Carbon Steel: Properties, Production, Examples and Applications

Carbon steel is an iron-carbon alloy, which contains up to 2.1 wt.% carbon. For carbon steels, there is no minimum specified content of other alloying elements, however, they often contain manganese. The maximum manganese, silicon and copper content should be less than 1.65 wt.%, 0.6 wt.% and 0.6 wt.%, respectively.

Types of carbon steel and their properties

Carbon steel can be classified into three categories according to its carbon content: low-carbon steel (or mild-carbon steel), medium-carbon steel and high-carbon steel . Their carbon content, microstructure and properties compare as follows:

| Carbon content (wt.%) | Microstructure | Properties | Examples |

| Low-carbon steel | < 0.25 | Ferrite, pearlite | Low hardness and cost. High ductility, toughness, machinability and weldability |

| Medium-carbon steel | 0.25 – 0.60 | Martensite | Low hardenability, medium strength, ductility and toughness |

| High-carbon steel | 0.60 – 1.25 | Pearlite | High hardness, strength, low ductility |

Carbon Steel Description

Grade:

1)GB: Q195, Q215, Q235A, Q235B, Q235C, Q235D, Q255A, 255B, Q275, Q295A, Q295B, Q345B, Q345C, Q345D, Q345E, Q390A, Q390B, Q390C,Q390D, Q390E, Q420, Q420B, Q420C, Q420D, Q420E, Q460D, Q460E, Q500D, Q500E, Q550D, Q550E, Q620D, Q620E, Q690D, Q690E

2)EN: S185,S235JR, S275JR, S355JR, S420NL, S460NL S500Q, S550Q, S620Q, S690Q

3)ASTM: Grade B, Grade C, Grade D, A36, Grade 36, Grade 40, Grade42, Grade 50, Grade 55, Grade 60, Grade 65, Grade 80

4)JIS: SS330, SPHC, SS400, SPFC, SPHD, SPHE

PRODUCT DETAILS

| AISI/SAE 8620 Carbon Steel Rod |

| 8620 steel rod is made of a kind of low alloy steel mainly composed of iron, carbon, silicon, manganese, phosphorus, sulfur, chromium, nickel and other elements. It has good hardenability and weldability, and can obtain excellent mechanical properties through heat treatment. |

| Product Parameters | ||||

| Product Name | AISI/SAE 8620 Carbon Steel Rod | |||

| Standard | EN/DIN/JIS/ASTM/BS/ASME/AISI, etc. | |||

| Common Round Rod Specifications | 3.0-50.8 mm, Over 50.8-300mm | |||

| Flat Steel Common Specifications | 6.35×12.7mm, 6.35×25.4mm, 12.7×25.4mm | |||

| Hexagon Rod Common Specifications | AF5.8mm-17mm | |||

| Square Rod Common Specifications | AF2mm-14mm, AF6.35mm, 9.5mm, 12.7mm, 15.98mm, 19.0mm, 25.4mm | |||

| Length | 1-6meters, Size Accept Custom | |||

| Diameter(mm) | Hot Rolling Round Rod | 25-600 | Cold Rolling Square Rod | 6-50.8 |

| Hot Rolling Square Rod | 21-54 | Cold Rolling Hexagon Rod | 9.5-65 | |

| Cold Rolling Round Rod | 6-101.6 | Forged Rebar | 200-1000 | |

| Surface Process | Bright, Polished, Black | |||

| Other Services | Machining(cnc), Centerless Grinding(cg), Heat Treatment, Annealing, Pickling, Polishing, Rolling, Forging, Cutting, Bending, Small Machining, etc. | |||

| Chemical Composition | |||||||

| C | Mn | Si | Mo | Cr | Ni | S | P |

| 0.18-0.23 | 0.70-0.90 | 0.15-0.35 | 0.15-0.25 | 0.40-0.60 | 0.40-0.70 | 0.035 | 0.04 |

| Mechanical Properties | |||||

| Grade | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation in 100-150 mm(%) | Reduction in Area | Hardness |

| SAE 8620 | ≥ 380 | ≥ 210 | ≥ 25 | ≥ 50 | ≤ 111HB |

| Scope of Application |

| AISI 8620 can be used in a variety of medium strength applications, such as camshafts, fasteners, gears and chains/chain pins. |

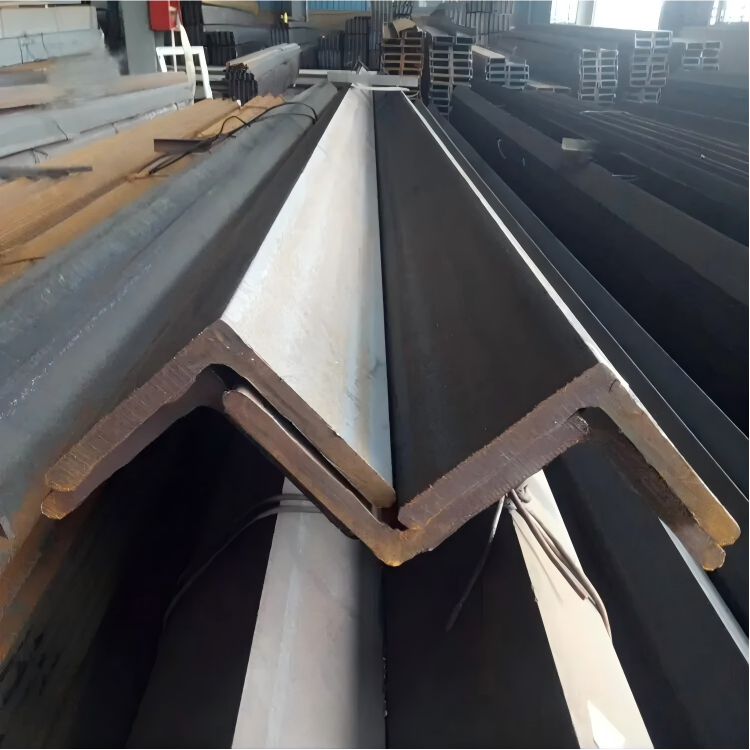

Product Display

Product Application

Product Packaging