1. Material Composition & Manufacturing Process

7050 aluminum alloy (AMS 4050, ASTM B247) represents an advanced aerospace-grade Al-Zn-Mg-Cu alloy engineered for superior damage tolerance and exceptional strength-to-weight ratio. The ultra-hard forged plate variant delivers optimized mechanical properties through precision thermomechanical processing:

Alloy Chemistry:

Zinc (Zn): 5.7-6.7% (primary strengthening element)

Copper (Cu): 2.0-2.6% (precipitation hardening)

Magnesium (Mg): 1.9-2.6% (strengthening precipitates)

Zirconium (Zr): 0.08-0.15% (grain structure control)

Base Material:

Aluminum (Al): ≥87.3% (balance)

Controlled Impurities:

Iron (Fe): ≤0.15% max

Silicon (Si): ≤0.12% max

Manganese (Mn): ≤0.10% max

Titanium (Ti): ≤0.06% max

Chromium (Cr): ≤0.04% max

Premium Forging Production Sequence:

Ingot Casting: Proprietary low-hydrogen, vacuum-degassed process

Homogenization: 470-490°C for 24-36 hours (computer-controlled ramp)

Surface Scalping: Minimum 10mm per surface to eliminate segregation

Pre-forging Preparation: Protective coating application

Multi-directional Forging:

Initial Deformation: 400-425°C

Intermediate Passes: 375-395°C

Final Deformation: 350-370°C

Minimum Deformation Ratio: 4:1

Post-forge Annealing: 413°C for 4-8 hours (stress equalization)

Precision Machining: Surface preparation for heat treatment

Solution Heat Treatment: 475-485°C for thickness-dependent time

Controlled Quenching: High-velocity polymer quench (>100°C/sec)

Cryogenic Treatment: Optional -75°C stabilization (24 hours)

Multi-stage Aging:

T7451: 120°C/8hr + 175°C/8hr

T7651: 120°C/6hr + 165°C/24hr

Full material traceability with digital process monitoring throughout manufacturing.

2. Mechanical Properties Of Ultra-Hard 7050 Forged Plate

| Property | Minimum | Typical | Test Standard | Performance Advantage |

| Ultimate Tensile Strength | 510 MPa | 540-570 MPa | ASTM E8/E8M | 15% higher than 7075-T6 |

| Yield Strength (0.2%) | 455 MPa | 480-510 MPa | ASTM E8/E8M | Superior aerospace loading capacity |

| Elongation (2 inch) | 8% | 10-13% | ASTM E8/E8M | Better damage tolerance than 7075 |

| Fracture Toughness (K₁c) | 30 MPa√m | 33-38 MPa√m | ASTM E399 | 25% improvement over 7075-T6 |

| Shear Strength | 305 MPa | 320-345 MPa | ASTM B769 | Enhanced joint performance |

| Bearing Strength (e/D=2.0) | 785 MPa | 800-850 MPa | ASTM E238 | Exceptional fastener capacity |

| Fatigue Strength (10⁷) | 145 MPa | 160-180 MPa | ASTM E466 | Superior cyclic loading resistance |

| Hardness (Brinell) | 140 HB | 150-165 HB | ASTM E10 | Improved wear resistance |

| Compressive Yield | 470 MPa | 490-520 MPa | ASTM E9 | Critical for compression structures |

Directionality Performance:

L/LT Tensile Strength Ratio: 1.05-1.08

L/ST Tensile Strength Ratio: 1.07-1.12

L/45° Tensile Strength Ratio: 1.02-1.06

Core-to-Surface Property Variation: <5% in thickness up to 150mm

3. Microstructural Engineering for Ultra-Hard Performance

Precision Thermomechanical Control:

Grain Structure Management:

Unrecrystallized, fibrous grain morphology

Controlled pancaking ratio: 5:1 to 8:1

Zr-stabilized substructure retention

Precipitate Engineering:

η’ (MgZn₂) primary strengthening

η (MgZn₂) overaging controlled

T (Al₂Mg₃Zn₃) phase distribution

S (Al₂CuMg) phase minimization

Quench Rate Control:

Critical cooling rate: >100°C/sec at surface

Core cooling rate: >60°C/sec minimum

Residual stress minimization through polymer quenchant

Multi-stage Aging Kinetics:

Nucleation stage: 120°C/6-8hr (GP zone formation)

Growth stage: 165-175°C/8-24hr (η’ precipitation)

Microstructural Characteristics:

Grain Size: ASTM 8-10 (15-30μm)

Dispersoid Size: 50-100nm (Al₃Zr)

Precipitate Density: >10^17/cm³

Recrystallized Fraction: <5% maximum

Texture: Strong brass {011}<211> component

Inclusion Rating: ≤0.3 per ASTM E45

Void Content: <0.1% volumetric

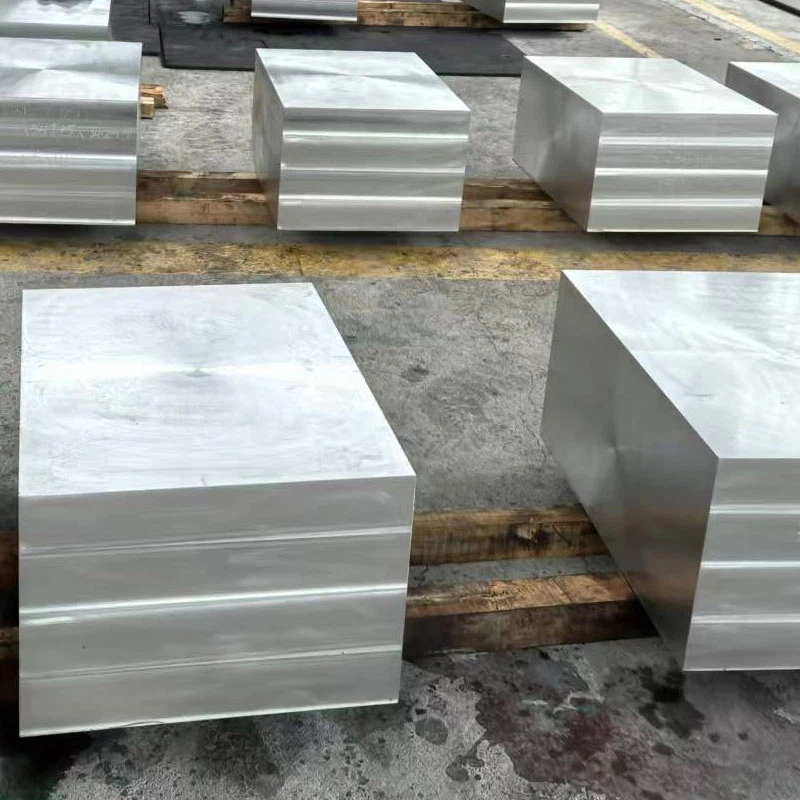

4. Dimensional Specifications & Tolerances

| Parameter | Standard Range | Aerospace Tolerance | Commercial Tolerance |

| Thickness | 20-250 mm | ±0.5mm or ±1%* | ±1.5mm or ±2%* |

| Width | 1000-2500 mm | ±2 mm | ±5 mm |

| Length | 2000-10000 mm | +10/-0 mm | +20/-0 mm |

| Flatness | N/A | 0.1% of length | 0.2% of length |

| Surface Roughness | N/A | 3.2 μm Ra max | 6.3 μm Ra max |

| Edge Straightness | N/A | 1 mm per meter | 3 mm per meter |

| Parallelism | N/A | 0.5% of thickness | 1.0% of thickness |

*Whichever is greater

Special Processing Options:

Near Net Shape Forging: Reduced machining allowance

Contour Pre-machining: 15mm minimum stock allowance

Stress Relief: Pre-machining stress equalization

Ultrasonic Inspection: 100% volumetric testing per AMS 2154

Density: 2.83 g/cm³ (±0.02)

Weight Formula: Thickness(mm) × Width(m) × Length(m) × 2.83 = Weight(kg)

5. Heat Treatment & Performance Optimization

| Temper Designation | Process Details | Optimized Properties | Target Applications |

| T7451 | Solution heat treat, controlled stretch (1.5-3%), stress relief, overaged | Best SCC resistance with high strength | Primary aircraft structures |

| T7651 | Solution heat treat, controlled stretch (1.5-3%), overaged (higher peak temperature) | Maximum strength with good SCC resistance | Critical load-bearing components |

| T7351 | Solution heat treat, stress relief by stretching, specially overaged | Optimal combination of strength/fracture toughness | Fatigue-critical structures |

| T74 | Solution heat treat, multi-stage overaging | Maximum SCC resistance | Marine/naval aerospace applications |

Heat Treatment Parameters:

Solution Temperature: 475-485°C

Soak Time: 1 hour per 25mm thickness (minimum)

Quench Delay: <10 seconds maximum

Quench Medium: Polymer concentration 12-18%

Quench Velocity: 3-5 m/sec minimum

Aging Temperature Control: ±3°C tolerance

Post-quench Storage: <8 hours at <20°C before aging

Material Response Characteristics:

Natural Aging: Significant property changes within 48 hours

Artificial Aging: 90% of properties developed in first aging stage

Thermal Stability: Maintains >95% of properties at 100°C

Cryogenic Performance: Increased strength at subzero temperatures

Stress Relief: 2-3% permanent deformation recommended

6. Machinability & Manufacturing Considerations

| Operation | Tool Material | Recommended Parameters | Special Considerations |

| High-Speed Milling | Premium carbide | Vc=500-1000 m/min, fz=0.1-0.25 mm | Climb milling essential |

| Deep Hole Drilling | Carbide coolant-fed | Vc=80-150 m/min, fn=0.15-0.35 mm/rev | Pecking cycle required |

| Turning | PCD/CBN inserts | Vc=600-1200 m/min | Sharp cutting edges vital |

| Threading | Premium HSS-E-PM | Vc=15-25 m/min | Thread rolling preferred |

| Reaming | Carbide reamers | Vc=40-70 m/min | H7 tolerance achievable |

| EDM | Copper electrodes | Low current settings | Recast layer removal required |

Machining Optimization Strategies:

Cutting Fluids: Water-soluble coolants (pH 8.5-9.5)

Tool Coatings: TiAlN or Diamond preferred

Chip Management: High-pressure (70+ bar) coolant

Clamping Force: Moderate (avoid distortion)

Feeds/Speeds: High speed, moderate feed approach

Tool Engagement: Maximum 60% of cutter diameter

Roughing Strategy: High-efficiency machining (HEM)

Finishing: Light cuts with high surface speed

7. Corrosion Resistance & Protection Systems

| Environment Type | Resistance Rating | Protection Method | Performance Expectation |

| Industrial Atmosphere | Moderate | Anodizing + primer/topcoat | 10+ years with maintenance |

| Marine Environment | Poor-Fair | Anodizing + chromated primer + topcoat | 5-8 years with maintenance |

| High-Humidity | Fair | Anodizing Type II or III | 3-5 years without topcoat |

| Chemical Exposure | Fair | Chemical conversion + sealed anodize | Application dependent |

| Stress Corrosion | Good (T7 tempers) | Overaging + surface compression | Significant improvement over 7075 |

| Exfoliation | Good (T7 tempers) | Proper heat treatment | EXCO rating of EA or better |

Surface Treatment Options:

Anodizing:

Type II (Sulfuric): 10-25μm

Type III (Hard): 25-75μm

Thin Film Sulfuric: 3-8μm

Tartaric-Sulfuric: 5-15μm

Conversion Coatings:

Chromate per MIL-DTL-5541 Class 1A

Trivalent chromium pretreatment

Sol-gel technology

Paint Systems:

High-solids epoxy primer

Polyurethane topcoat

Rain erosion coatings

Specialty anti-corrosion primers

Mechanical Surface Enhancement:

Shot peening (0.008-0.012A intensity)

Laser shock peening

Burnishing

8. Physical Properties for Engineering Design

| Property | Value | Design Significance |

| Density | 2.83 g/cm³ | Weight-critical structures |

| Melting Range | 490-630°C | Welding/heat treatment limitations |

| Thermal Conductivity | 153-167 W/m·K | Heat dissipation capability |

| Electrical Conductivity | 35-40% IACS | EMI shielding applications |

| Specific Heat | 860 J/kg·K | Thermal mass calculations |

| Thermal Expansion (CTE) | 23.5 ×10⁻⁶/K | Thermal stress prediction |

| Young’s Modulus | 71.7 GPa | Structural stiffness |

| Poisson’s Ratio | 0.33 | Elasticity modeling |

| Fatigue Crack Growth Rate | da/dN = 3×10⁻⁹(ΔK)³·⁵ | Damage tolerance design |

| Fracture Energy (G₁c) | 28-32 kJ/m² | Impact resistance assessment |

9. Quality Assurance & Testing Protocolsption

Mandatory Inspection Regime:

Chemical Composition:

Optical emission spectroscopy

Verification of all major elements and impurities

Mechanical Testing:

Full tensile test (L, LT, ST directions)

K₁c fracture toughness testing

Hardness survey (25mm grid minimum)

Non-Destructive Testing:

Ultrasonic inspection per AMS-STD-2154 Class A

Penetrant inspection of critical surfaces

Eddy current testing (optional)

Microstructural Analysis:

Grain size and morphology

Recrystallization assessment

Inclusion rating per ASTM E45

Production Testing:

Heat treatment parameters verification

Quench sensitivity testing

Electrical conductivity mapping

Certification Documentation:

Material Test Report (MTR) per EN 10204 3.1/3.2

Chemical analysis certification

Mechanical properties certification

Heat treatment chart records

NDT reports with acceptance criteria

Temper verification documentation

Process control parameters

Statistical process data summary

Lot traceability information

10. Applications & Performance Advantages

Primary Aerospace Applications:

Bulkhead structures

Wing spars and carry-through structures

Landing gear components

Fuselage frames and longerons

Thick section structural members

Upper wing skins

High-load fittings

Missile structures

Structural backup hardware

Critical connection fittings

Performance Advantages vs. 7075:

10-15% higher tensile strength

20-25% improved fracture toughness

Superior stress corrosion resistance

Enhanced exfoliation corrosion resistance

Better fatigue crack growth resistance

Improved damage tolerance

Higher residual strength after impact

Better thermal stability

Superior machinability in thick sections

Enhanced through-thickness properties

11. Storage & Handling RequirementsProducts Description

Material Handling Protocol:

Storage Environment:

Temperature: 15-25°C

Humidity: <65% RH

Protection from precipitation

Isolation from steel products

Lifting Guidelines:

Multi-point lifting with spreader bars

Non-metallic slings