1. Material Composition & Manufacturing Process

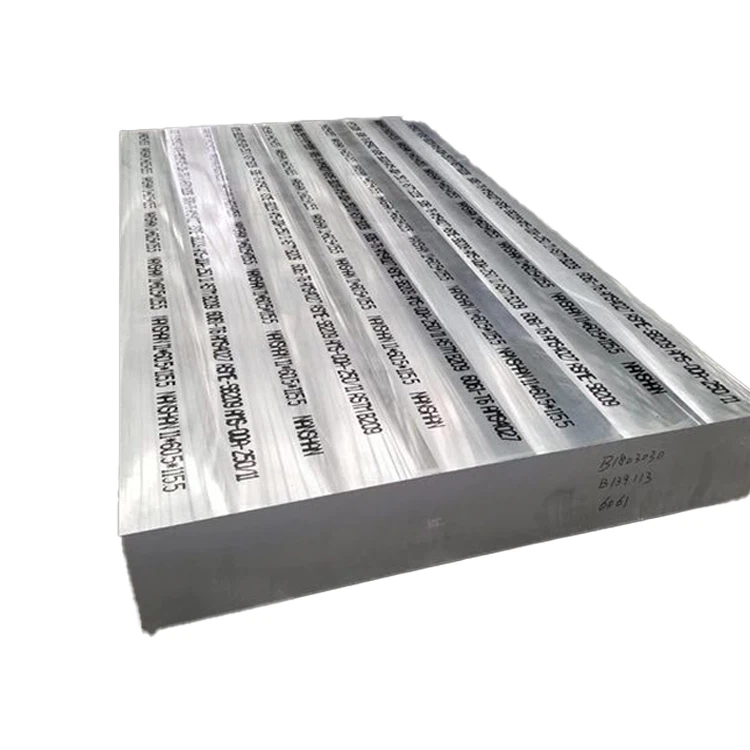

6061 aluminum alloy (ASTM B209, AMS 4025) is a heat-treatable Al-Mg-Si alloy engineered for versatility and excellent mechanical properties. Ultra-thick forged plate variants (>150mm) offer exceptional structural integrity through specialized manufacturing:

Alloy Chemistry:

Magnesium (Mg): 0.8-1.2% (Mg₂Si precipitation)

Silicon (Si): 0.4-0.8% (Mg₂Si formation)

Copper (Cu): 0.15-0.40% (strengthening)

Chromium (Cr): 0.04-0.35% (corrosion resistance)

Base Material:

Aluminum (Al): ≥97.5% (balance)

Controlled Impurities:

Iron (Fe): ≤0.7% max

Zinc (Zn): ≤0.25% max

Titanium (Ti): ≤0.15% max

Manganese (Mn): ≤0.15% max

Advanced Ultra-Thick Forging Process:

Ingot Casting: Premium double-degassed 7000-12000kg ingots

Pre-homogenization Inspection: Ultrasonic testing to Level A

Homogenization: 580-590°C for 24-36 hours (core temperature controlled)

Scalping: Surface machining to remove segregation zone

Preheating: Staged heating to 450-470°C with ±5°C uniformity

Open-Die Forging:

Multi-directional deformation

10,000-15,000 ton hydraulic press

Deformation ratio 3:1 minimum

Intermediate Annealing: 410°C for 6-8 hours when required

Solution Heat Treatment: 530-550°C for 2-5 hours (thickness dependent)

Precision Quenching: Polymer quench with controlled cooling rate 45-90°C/min

Straightening: Hydraulic press with distributed load

Artificial Aging: T6 or T651 temper at 170-190°C for 8-12 hours

Full quality documentation with melt-to-product traceability.

2. Mechanical Properties of Ultra-Thick Forged PlateProducts Description

| Property | Minimum | Typical | Test Standard | Significance for Ultra-Thick Sections |

| Ultimate Tensile Strength | 290 MPa | 310-330 MPa | ASTM B557 | Maintained through entire cross-section |

| Yield Strength (0.2% offset) | 240 MPa | 260-280 MPa | ASTM B557 | Less than 10% variation core to surface |

| Elongation (2 inch) | 8% | 10-14% | ASTM B557 | Critical for thick section ductility |

| Shear Strength | 170 MPa | 180-210 MPa | ASTM B769 | Joint design parameter for bolted connections |

| Bearing Strength (e/D=2.0) | 430 MPa | 450-480 MPa | ASTM E238 | Fastener hole performance |

| Fatigue Strength (10⁷) | 95 MPa | 100-120 MPa | ASTM E466 | Long-term cyclic loading resistance |

| Hardness (Brinell) | 95 HB | 95-105 HB | ASTM E10 | ≤5% variation through thickness |

| Fracture Toughness (K₁C) | 29 MPa√m | 32-37 MPa√m | ASTM E399 | Critical for damage tolerance |

| Through-Thickness Reduction | 6% min | 8-12% | ASTM E8 | Z-direction ductility |

Directionality (Typical Ratios):

L vs. LT: ≤1.05:1 tensile strength ratio

L vs. ST: ≤1.10:1 tensile strength ratio

Core vs. Surface: ≤1.08:1 yield strength ratio

3. Ultra-Thick Forging Microstructure ControlProducts Description

Thickness-Specific Processing:

Deformation Distribution:

Multi-axial forge compression

Minimum 25% reduction in final pass

Constant temperature control through section

Quench Rate Management:

Polymer concentration: 12-18%

Agitation velocity: 2.5-3.5 m/s

Temperature rise control: <15°C max

Thermal Gradient Mitigation:

Isothermal holds at critical temperatures

Core temperature monitoring during processing

Controlled cooling rate: 60-80°C/min surface, 40-55°C/min core

Microstructural Characteristics:

Grain Size: ASTM 4-6 (40-70μm)

Recrystallization: >85% recrystallized structure

Precipitate Distribution:

Primary Mg₂Si: 0.5-2μm

β” needles: 4-8nm in diameter

Q-phase and B’-phase controlled

Dispersoid Density: 1-3×10⁶/mm²

Texture: Modified cube with reduced anisotropy

Inclusion Rating: ≤0.5 per ASTM E45

Maximum Grain Size Variation: 2 ASTM numbers through thickness

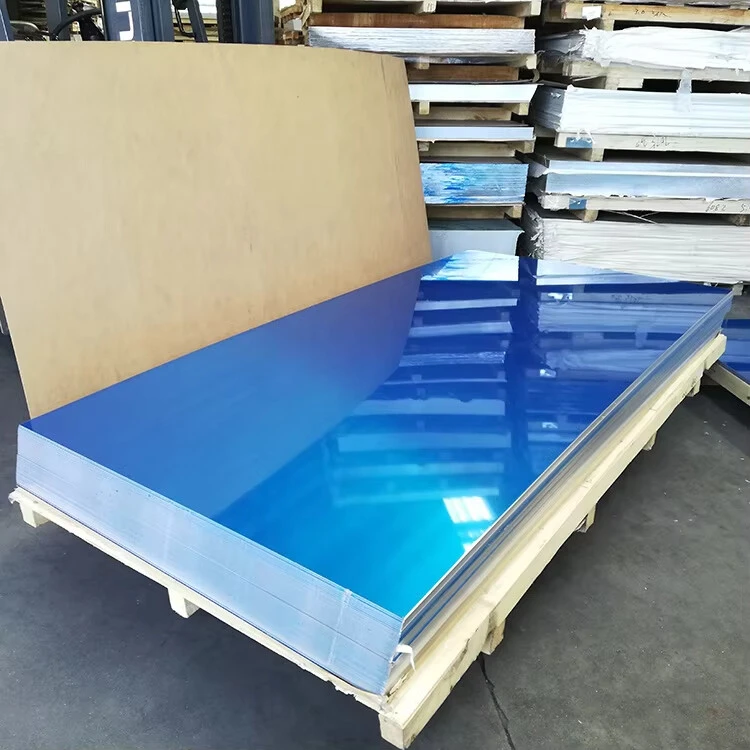

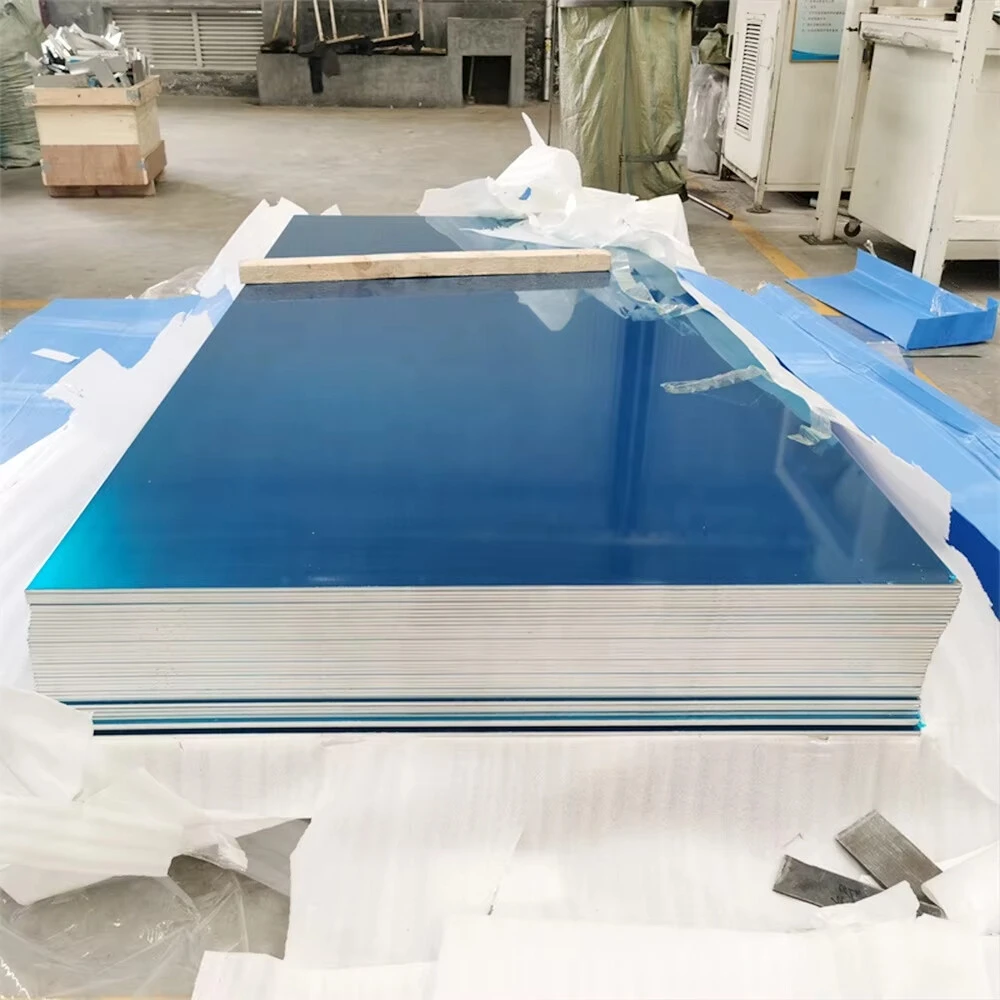

4. Dimensional Specifications & Tolerances

| Parameter | Standard Range | Precision Tolerance | Commercial Tolerance |

| Thickness | 150-500 mm | ±3 mm | ±5 mm |

| Width | 1000-3500 mm | ±5 mm | ±8 mm |

| Length | 2000-12000 mm | +15/-0 mm | +25/-0 mm |

| Flatness | N/A | 0.15% of length | 0.30% of length |

| Parallelism | N/A | 0.5% of thickness | 1.0% of thickness |

| Edge Straightness | N/A | 1 mm/1000 mm | 2 mm/1000 mm |

| Surface Roughness | N/A | 6.3 μm Ra max | 12.5 μm Ra max |

Specialized Parameters:

Machining Allowance: 15mm per side recommended

Stress Relief: Required before precision machining

Ultrasonic Testing: 100% volumetric inspection

Density: 2.70 g/cm³ (±0.01 g/cm³)

Weight Formula: Thickness(mm) × Width(m) × Length(m) × 2.70 = Weight(kg)

Maximum Single Piece Weight: 25,000 kg

5. Heat Treatment & Property Optimization

| Temper Designation | Process | Applications | Key Properties |

| T651 | Solution treated, stress relieved by stretching (1.5-3%), artificial aging | Primary aerospace, defense, moldmaking | Maximum strength with good stress corrosion resistance |

| T6511 | Solution treated, stress relieved by stretching (controlled), artificially aged | Critical structural components, precision parts | Excellent dimensional stability with high strength |

| T6510 | Solution treated, minimal stress relief, artificially aged | Complex geometries, bridge components | Balanced properties with minimized distortion |

| T73 | Solution treated, overaged | High temperature service, stress corrosion critical applications | Superior stress corrosion resistance, thermal stability |

Solution Heat Treatment Parameters:

Temperature: 530-550°C

Time: 25 min/inch of thickness (minimum 2 hours)

Temperature Uniformity: ±5°C maximum variation

Quenching Delay: <15 seconds maximum

Transfer Equipment: Specialized handling fixtures

Artificial Aging Options:

T6 Cycle: 175-185°C for 8-10 hours

T651 Cycle: 175-185°C for 6-8 hours

T73 Cycle: Dual stage (175°C/4hr + 215°C/8hr)

6. Machining & Fabrication Characteristics

| Operation | Tool Material | Recommended Parameters | Notes for Ultra-Thick Plate |

| Heavy Milling | Carbide inserts | Vc=300-700 m/min, fz=0.15-0.25 mm | Climb milling preferred |

| Deep Hole Drilling | Carbide drills | Vc=60-120 m/min, fn=0.15-0.30 mm/rev | Peck cycle required |

| Boring | PCD tooling | Vc=500-1000 m/min | Dampened boring bars essential |

| Face Milling | Carbide face mills | Vc=350-800 m/min | High positive rake geometry |

| Tapping | HSS-E-PM taps | Vc=15-30 m/min | H-limits preferred |

| Sawing | Carbide-tipped | 40-60 m/min, 2-3 teeth engaged | Flood cooling mandatory |

Special Considerations:

Residual Stress Management: Release 75% of stock prior to final machining

Fixturing: Distributed clamping force to prevent distortion

Tool Engagement: Maximum 60% cutter diameter width of cut

Coolant: High-pressure (70+ bar) for deep features

Heavy Machining: Maximum 5mm depth of cut per pass

Heat Generation: Monitor workpiece temperature during machining

Chip Evacuation: Critical for deep pocket milling

7. Corrosion Resistance & Surface Treatmentson

| Environment | Performance | Protection Method | Service Life Expectation |

| Industrial Atmosphere | Very Good | Anodizing Type II/III | 15-20+ years |

| Marine Environment | Good | Chromate conversion + paint | 10-15+ years |

| Fresh Water | Excellent | Minimal protection needed | 30+ years |

| Chemical Processing | Fair to Good | PTFE impregnated anodize | Application specific |

| High Temperature | Fair | High-temperature coatings | 5-10+ years |

| Buried Service | Very Good | Bituminous coatings | 40+ years |

Surface Treatment Options:

Anodizing:

Type II: 10-25μm thickness

Type III (Hard): 25-75μm thickness

PTFE impregnated options

Conversion Coatings:

Chromate conversion (MIL-DTL-5541)

Trivalent chromium treatments

Non-chromate alternatives (Ti/Zr based)

Painting Systems:

Epoxy primer + polyurethane topcoat

Powder coating (190-210°C cure)

High-solids industrial coatings

Special Surface Preparations:

Mechanical: Grit blast Sa 2.5

Chemical: Acid etch and desmut

Laser texturing for specialized applications

8. Physical Properties for Design Engine

ering

| Property | Value | Significance in Ultra-Thick Applications |

| Density | 2.70 g/cm³ | Weight calculation for large components |

| Melting Range | 582-652°C | Stress relieving limitations |

| Thermal Conductivity | 167 W/m·K | Heat dissipation in large masses |

| Electrical Conductivity | 43% IACS | EMI shielding applications |

| Specific Heat | 896 J/kg·K | Thermal inertia in processing |

| Thermal Expansion | 23.6 ×10⁻⁶/K | Differential expansion in assemblies |

| Young’s Modulus | 68.9 GPa | Stiffness in structural applications |

| Poisson’s Ratio | 0.33 | Dimensional changes under load |

| Damping Capacity | 0.008-0.01 | Vibration characteristics |

| Thermal Diffusivity | 69 mm²/s | Processing heat transfer rate |

9. Quality Control & Testing Protocols

Mandatory Testing Protocol:

Chemical Analysis: Optical emission spectroscopy

Mechanical Testing:

Tensile testing (surface, t/4, t/2 positions)

Hardness survey (traverse and longitudinal)

Non-Destructive Evaluation:

Ultrasonic inspection per AMS-STD-2154 Class A

Penetrant inspection of critical surfaces

Metallurgical Evaluation:

Grain size measurement per ASTM E112

Inclusion rating per ASTM E45

Microstructural analysis for precipitate distribution

Dimensional Inspection:

CMM verification of critical dimensions

Laser scanning for profile accuracy

Thickness mapping at defined grid points

Certification Package:

Material Test Report (EN 10204 Type 3.1/3.2)

Chemical composition certificate

Mechanical property certification

Heat treatment chart records

NDT reports and acceptance criteria

Dimensional inspection reports

Traceability documentation (melt to product)

Compliance declarations (RoHS, REACH, etc.)

10. Industrial Applications & Handling

Primary Applications:

Aerospace structural components

Defense system platforms

Semiconductor manufacturing equipment

Plastic injection mold bases

Bridge structural elements

Nuclear industry components

Heavy transportation frames

Machine tool structural bases

Rolling mill backup rolls

High-strength fixturing elements

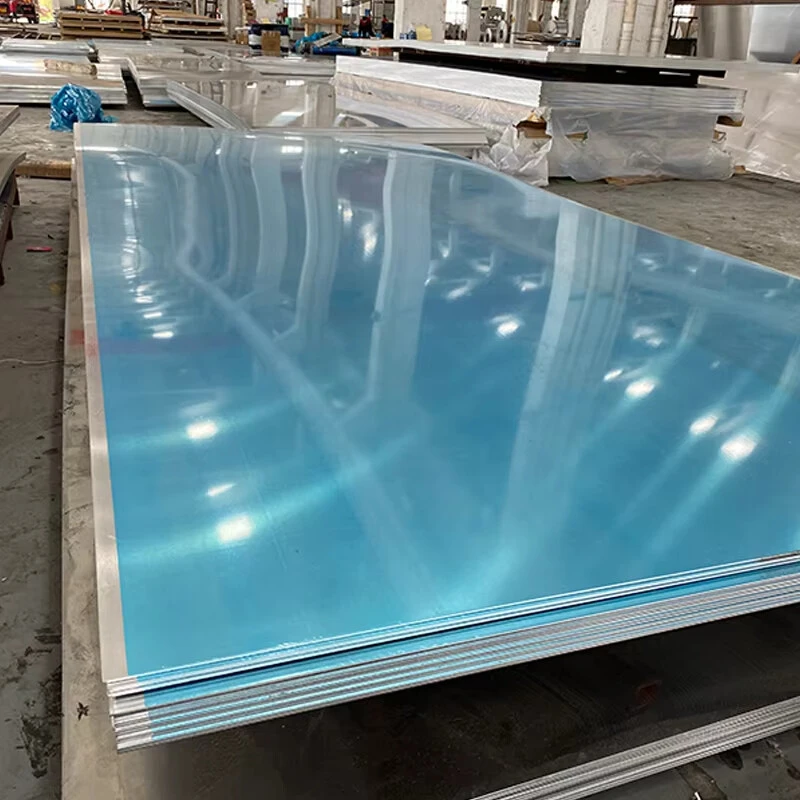

Material Handling Protocol:

Lifting Requirements:

Minimum 4-point lifting system

Spreader bars mandatory

Maximum sling angle: 60° from horizontal

Lifting capacity: Safety factor of 3:1

Storage Conditions:

Indoor storage recommended

Support at minimum 300mm intervals

Stacking height limitation: 1.5m maximum

Avoid direct contact with dissimilar metals

Transportation:

Secure with non-metallic strapping

Vibration dampening materials

Edge protection mandatory

Moisture protection during transit

Machining Preparation:

Temperature stabilization: 24 hours minimum

Stress relieving recommended before critical machining

Sequential material removal plan

Progressive clamping force adjustment

11. Design Considerations for Ultra-Thick Sections

Structural Design Factors:

Section Modulus Optimization:

Utilize full thickness advantage for bending resistance

I-beam equivalent performance with reduced weight

Consider internal web structures in very thick sections

Fastener Selection:

Minimum edge distance: 2× bolt diameter

Recommended thread engagement: 1.5× bolt diameter

Torque specifications: 65-75% of standard steel values

Bearing strength utilization up to 480 MPa

Thermal Management:

Allow for thermal expansion of 2.36mm per meter per 100°C

Design expansion joints for large structures

Consider thermal gradients during welding

Dynamic Loading:

Fatigue endurance limit approximately 100 MPa

Apply stress concentration factors at design phase

Shot peening for fatigue-critical surfaces

Weight Reduction Strategies:

Pocket milling of non-critical areas

Selective thickness distribution

Hybrid structures with composite elements

Topology optimization for