1. Material Composition & Standards

Conforming to ASTM B210, AMS 4005, and EN 573-3 standards, 5052 aluminum tubing features a magnesium-enriched alloy composition optimized for marine and industrial applications:

Primary Elements:

Magnesium (Mg): 2.2-2.8% (enhances strength and corrosion resistance)

Chromium (Cr): 0.15-0.35% (improves stress corrosion cracking resistance)

Base Material:

Aluminum (Al): ≥96.8% (balance)

Impurity Limits:

Iron (Fe): ≤0.40%

Silicon (Si): ≤0.25%

Copper (Cu): ≤0.10%

Manganese (Mn): ≤0.10%

Zinc (Zn): ≤0.10%

The alloy is supplied in strain-hardened tempers including H32 (¼ hard), H34 (½ hard), and H38 (full hard) per ASTM B210 specifications. Third-party verification through NADCAP AC7117 ensures consistent chromium distribution critical for pitting resistance in chloride environments.

5052 demonstrates superior ductility-to-strength ratios ideal for pressure vessels and structural forms:

| Property |

H32 Temper |

H34 Temper |

H38 Temper |

Test Standard |

| Tensile Strength (Rm) |

195-240 MPa |

230-275 MPa |

270-305 MPa |

ASTM E8 |

| Yield Strength (Rp0.2) |

160-195 MPa |

195-230 MPa |

250-285 MPa |

ASTM E8 |

| Elongation at Break (%) |

12-18% |

8-12% |

5-8% |

ASTM E8 |

| Shear Strength |

125 MPa |

145 MPa |

170 MPa |

ASTM B769 |

| Burst Pressure (OD20×WT2mm) |

18.5 MPa |

23.1 MPa |

28.7 MPa |

ASTM B641 |

| Fatigue Endurance (10⁷ cycles) |

100 MPa |

115 MPa |

130 MPa |

ISO 1099 |

| Impact Toughness (20°C) |

27 J |

22 J |

15 J |

ASTM E23 |

Retains >95% strength at -40°C and demonstrates consistent compressive yield strength within 2% of tensile values.

3. Heat Treatment & Processing

As a non-heat-treatable alloy, mechanical properties are achieved through strain hardening:

Cold Working Process

Hot Rolling: Initial reduction at 400-450°C to 12mm thickness

Cold Drawing: 15-25% area reduction per pass

H32: 8-15% total reduction

H34: 16-24% total reduction

H38: 25-30% total reduction

Stabilization: 150°C for 60 minutes to relieve residual stresses

Resulting Microstructure

Grain size: ASTM 7-10 (5-15μm elongated grains)

Dislocation density: 10⁹/cm² (H32) to 10¹⁰/cm² (H38)

Texture coefficient: <0.7 for deep drawing applications

Recrystallization threshold: 260-280°C

Post-forming annealing is permitted at 345°C for stress relief without property degradation.

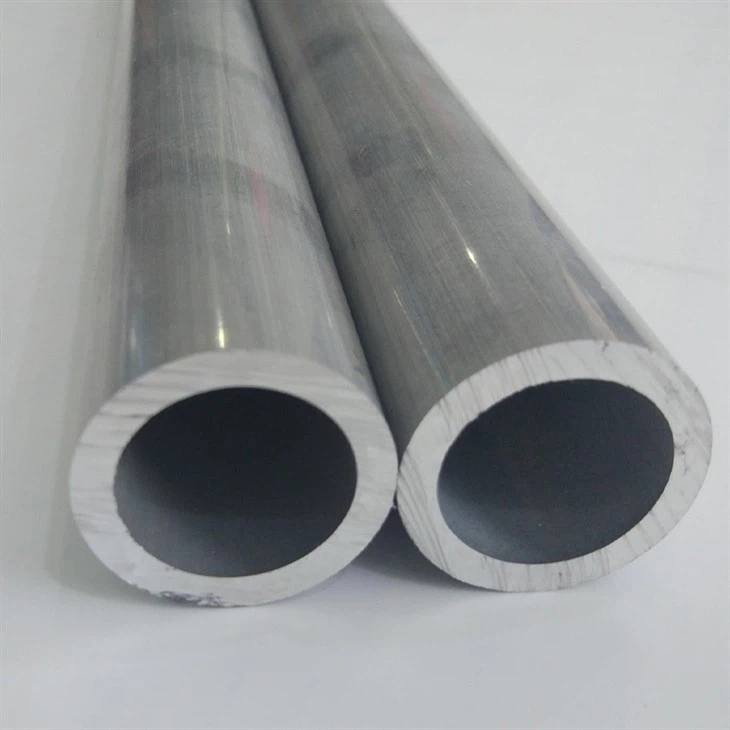

4. Dimensions & Customization

Manufactured to marine engineering standards with enhanced corrosion allowances:

| Parameter |

Standard Range |

Precision Tolerance |

Custom Options |

| Outer Diameter |

6-300 mm |

±0.1% OD |

Oval/rectangular profiles |

| Wall Thickness |

0.5-12 mm |

+10%/-5% WT |

Variable wall sections |

| Length |

1-12 m |

+3mm/-0mm |

Coiled lengths 30m+ |

| Straightness |

– |

1mm/m max. |

±0.3mm/m |

| Ovality |

– |

≤1.0% TIR |

≤0.3% TIR |

| Bend Radius (min) |

1.5× OD |

±5% |

Tight radius: 0.75× OD |

Fabrication Capabilities:

CNC rotary draw bending (up to 180° bends)

Hydroforming for complex cross-sections

Expanded ends for tube-to-tube joining

Thread rolling per ASME B1.20.1

5. Corrosion Resistance Properties

Environmental Performance Ratings

| Environment |

ISO 9223 Rating |

Corrosion Rate (μm/yr) |

Protection Recommendation |

| Marine Offshore |

RC5 (Excellent) |

<5 μm/yr |

MIL-PRF-85582 marine coat |

| Chemical Process |

RC4 (Good) |

8-20 μm/yr |

PVDF lining |

| Coastal Atmosphere |

RC4 (Good) |

5-15 μm/yr |

Anodize Type IIB |

| Deicing Salt Exposure |

RC4 (Good) |

10-25 μm/yr |

Ceramic-epoxy coating |

Protection Systems:

Anodizing:

Type IIB (hard coat): 25-75μm thickness

Chromic acid (Type I): 5-8μm for thin walls

Coatings:

Fluoropolymer systems (PVDF): 30-50μm DFT (30-year warranty)

Ceramic-modified epoxies: 200μm DFT

Thermal spray aluminum (TSA): 150μm arc-sprayed layer

Galvanic Isolation: Dielectric unions for dissimilar metal connections

6. Machinability Characteristics

Optimization Parameters

| Operation |

Tool Material |

Speed (m/min) |

Feed (mm/rev) |

Notes |

| Turning |

Carbide K01 |

300-500 |

0.20-0.40 |

Positive rake geometries |

| Milling |

Carbide K10 |

400-600 |

0.10-0.20 |

6-flute end mills preferred |

| Drilling |

TiN Coated |

70-100 |

0.05-0.12 |

118° point angle |

| Tapping |

HSS-Co8 |

15-25 |

Pitch matched |

85% thread depth |

Performance Metrics:

Machinability index: 80% (baseline: 2011-T3=100%)

Surface roughness: Ra 0.4μm achievable

Built-up edge resistance: Class 3 (ISO 3685)

Chip formation: Continuous chips requiring breakers

Coolant recommendation: 7-10% emulsion concentration

7. Weldability & Joining Methods

Exceptional Fusion Weldability

GTAW and GMAW approved per AWS D1.2 procedures:

Gas Tungsten Arc Welding (GTAW)

Filler wire: ER5356 (AlMg5Cr) or ER5556

Shielding gas: Ar +25-30% He mixture

Heat input: <1.2 kJ/mm

Interpass temp: <100°C

Tube-to-Tube Joining

Orbital Welding:

Rotation speed: 4-10 RPM

Current pulsation: 150Hz with 40% background

Brazing:

Aluminum-silicon filler: BAISi-4 (4047 alloy)

Torch temperature: 590-620°C

Mechanical Connections:

Swagelok fittings: Up to 400bar working pressure

Victaulic grooved couplings: Size range 15-300mm

| Property |

Value |

Test Standard |

| Density |

2.68 g/cm³ |

ASTM B311 |

| Thermal Conductivity (25°C) |

138 W/m·K |

ASTM E1461 |

| CTE (20-100°C) |

23.8 μm/m·°C |

ASTM E228 |

| Electrical Resistivity |

47 nΩ·m |

ASTM B193 |

| Modulus of Elasticity |

70.3 GPa |

ASTM E111 |

| Magnetic Permeability |

1.02 μH/m |

ASTM A342 |

| Sound Velocity |

5150 m/s |

ASTM E494 |

| Emissivity (100°C) |

0.10 (polished) |

ASTM C835 |

| Reflectivity (visible) |

75-85% |

ASTM E903 |

9. Surface Quality Standards

Seamless (ASTM B210) or welded (ASTM B491) construction

Surface finishes:

Mill finish: Ra 0.5-1.5μm

Smooth finish: Ra 0.2-0.5μm (for sanitary applications)

Mirror polish: Ra <0.025μm achievable

Defect classification (EN 10246-14):

Scratches: ≤0.03mm depth

Die lines: ≤0.1% OD

Inclusion size: ≤0.2mm

No visible seam on welded tubes

Cleaning protocols:

Electropolishing per ASTM B912

Degreasing to AMS 2658 Class D

10. Certifications & Testing

Non-Destructive Testing

Eddy Current: ASTM E309 with 0.25mm sensitivity

Hydrostatic: 1.5× design pressure for 60 seconds

Helium Leak Testing: <10⁻⁶ mbar·L/s sensitivity

Ultrasonic Wall Measurement: ±0.01mm resolution

Material Certifications

NORSOK M650 approved for offshore applications

PED 2014/68/EU Annex I compliance

FDA CFR 21.177.1500 for food contact

AD2000-Merkblatt HP0 approved for pressure vessels

Lloyd’s Register Type Approval Certificate

Marine Applications: Hull penetrations, railings, masts, heat exchangers, fuel lines, and desalination components where seawater corrosion resistance is paramount.

Packaging: VCI foam-end caps + shrink-wrap bundles, wooden crates with polyethylene moisture barrier. Standard lead time: 4 weeks for stocked sizes.