1. Material Composition & Manufacturing Process

5052 aluminum alloy (ASTM B209, AMS 4002) features a magnesium-chromium alloying system optimized for corrosion resistance and formability:

Alloy Chemistry:

Magnesium (Mg): 2.2-2.8% (solution strengthening)

Chromium (Cr): 0.15-0.35% (corrosion resistance)

Iron (Fe): ≤0.40% max

Silicon (Si): ≤0.25% max

Copper (Cu): ≤0.10% max

Base Material:

Aluminum (Al): ≥96.7% (balance)

Trace Elements:

Zinc (Zn): ≤0.10% max

Manganese (Mn): ≤0.10% max

Titanium (Ti): ≤0.15% max

Advanced Manufacturing Process:

Continuous Casting: 680-720°C molten metal temperature

Hot Rolling: Initial reduction at 450-510°C

Cold Rolling: Final gauge reduction (30-80% reduction)

Stabilization Treatment:

H32: Slightly strain hardened + stabilized

H34: Medium strain hardened + stabilized

H38: Hard strain hardened + stabilized

Surface Treatment: Mill finish, brushed or embossed options

Certified to ASME SB209 and EN 485 standards with full traceability documentation.

2. Mechanical Properties by Temper State

| Property | O Temper | H32 Temper | H34 Temper | Test Standard |

| Ultimate Tensile Strength | 170-215 MPa | 230-265 MPa | 260-290 MPa | ASTM B557 |

| Yield Strength (Rp0.2) | 65-105 MPa | 195-215 MPa | 220-240 MPa | ASTM B557 |

| Elongation (%) | 18-25% | 8-14% | 6-10% | ASTM B557 |

| Shear Strength | 125-145 MPa | 155-175 MPa | 170-190 MPa | ASTM B831 |

| Bearing Strength | 310-350 MPa | 440-480 MPa | 480-520 MPa | ASTM E238 |

| Fatigue Strength (10⁷) | 90-115 MPa | 110-135 MPa | 120-145 MPa | ASTM E466 |

| Hardness (Brinell) | 47-52 HB | 60-68 HB | 68-75 HB | ASTM E10 |

| Impact Toughness | 25-30 J | 20-24 J | 15-20 J | ASTM E23 |

3. Heat Treatment & Microstructure Control

Strain Hardening Mechanism:

Cold rolling reduction determines final properties:

H32: 8-15% reduction

H34: 15-22% reduction

H38: 30-40% reduction

Stabilization Treatment: 120-160°C for 1-3 hours

Microstructural Characteristics:

Grain Size: ASTM 5-6 (40-60μm)

Dispersoid Phases:

Al₃Mg₂ particles (2-5nm)

Al₇Cr precipitates (10-30nm)

Dislocation Density:

O temper: 1×10⁸/cm²

H38 temper: 6×10¹⁰/cm²

Texture Components: Strong Brass {110}<112>

Recrystallization Fraction: Fully recrystallized in O temper

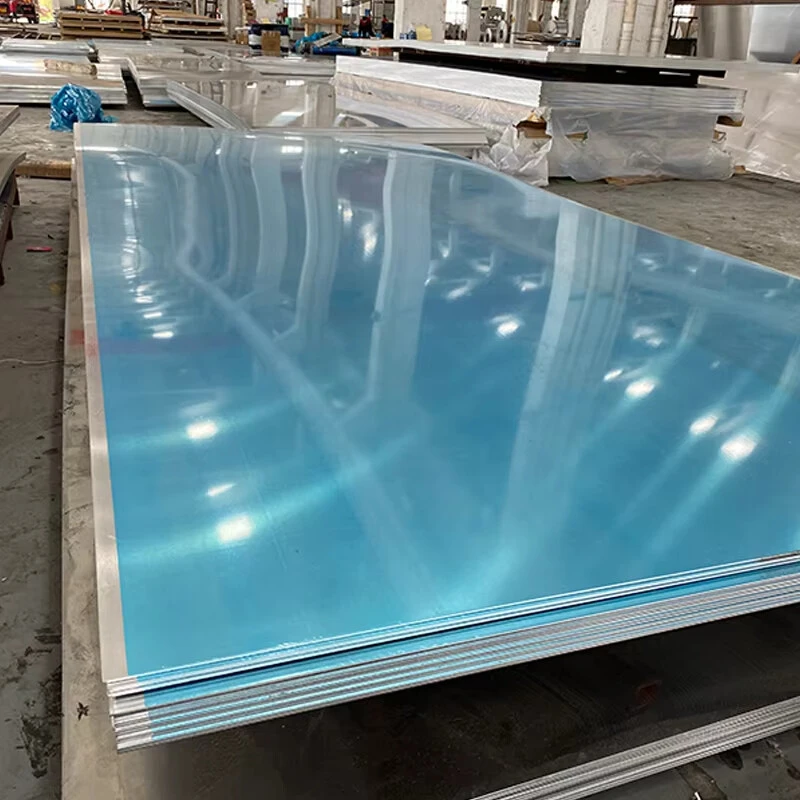

4. Dimensional Specifications for Plate

| Parameter | Standard Range | Precision Tolerance | Special Capabilities |

| Thickness | 0.5-150 mm | ±1-3% (varies by gauge) | Up to 200 mm |

| Width | 1000-3000 mm | ±5-15 mm | Up to 4500 mm |

| Length | 2000-12000 mm | ±10-30 mm | Up to 18,000 mm |

| Flatness | 5-15 mm/m | 1-3 mm/m (precision) | – |

| Surface Roughness | 0.4-1.2 μm Ra | 0.2-0.4 μm Ra (polished) | Mirror finish |

| Edge Condition | Mill edge | Squared or beveled | CNC edge profiling |

Forming Capabilities:

Stretch Forming: Up to 30% elongation

Deep Drawing: LDR of 1.8-2.2

Hydroforming: Complex shapes

Brake Forming: Minimum bend radius 1t (O temper)

Roll Forming: Continuous profiles

5. Corrosion Resistance Performance

| Environment | Performance Rating | Corrosion Rate | Protection Methods |

| Seawater Immersion | Excellent | <0.002 mm/year | Alodine 1200S conversion |

| Coastal Atmosphere | Excellent | 0.001-0.003 mm/year | Paint systems |

| Chemical Exposure | Good | 0.01-0.1 mm/year | PVDF coating |

| Automotive Salt Spray | Excellent | ASTM B117 Rating A | E-coat pretreatment |

| Stress Corrosion | Excellent | SCC threshold >50MPa | – |

Surface Treatment Options:

Mill Finish: Standard protective film

Anodizing: Decorative or hard coat

Powder Coating: Multiple color options

PVDF Coating: Superior weather resistance

Chromate Conversion: Alodine 600 series

Embossed Surfaces: Diamond or linear patterns

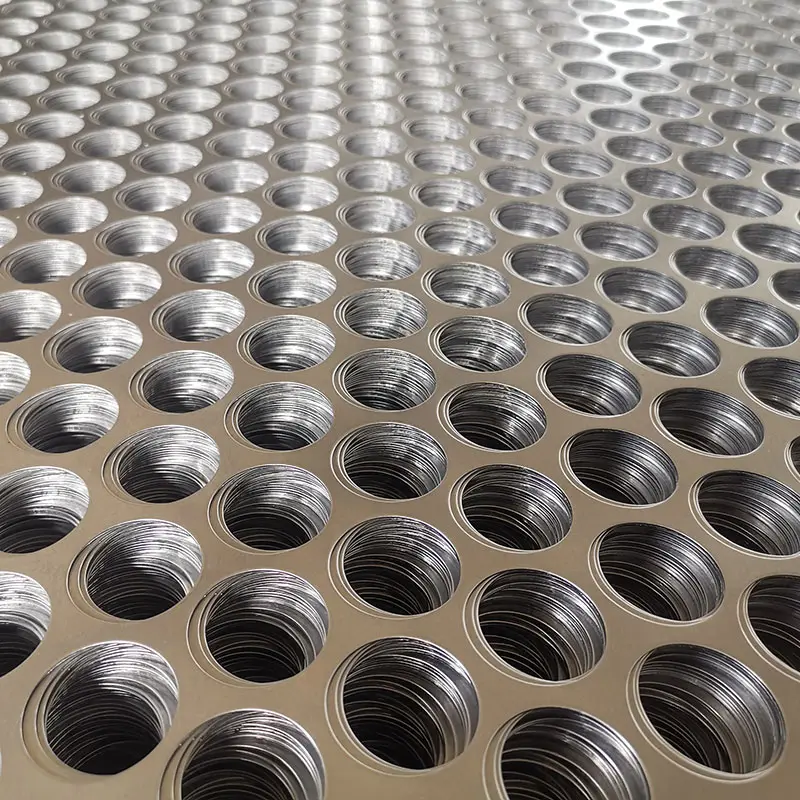

6. Machining & Fabrication Properties

| Operation | Tool Material | Recommended Parameters | Quality Output |

| Waterjet Cutting | High-pressure | 3500-4000 bar, 8-15 mm/min | ±0.1-0.3 mm |

| Laser Cutting | Fiber laser | 3-6 kW power, 5-20 m/min | Ra 3-8 μm |

| Routing | Carbide tools | 3000-5000 RPM, 1500-3000 mm/min | Burr-free edges |

| Punching | HSS tooling | 60-100 strokes/min | IT12 tolerance |

| Blanking | D2 tool steel | Clearance 8-12% material thick | Minimum 1.5t radius |

Fabrication Advantages:

Weldability: Excellent without preheat

Shearability: Low tool wear rate

Formability: High ductility in annealed state

Joinability: Compatible with all standard methods

Polishability: Excellent surface finishing characteristics

7. Welding & Joining Technologies

Optimal Welding Processes:

Gas Metal Arc Welding (GMAW):

Wire: ER5356 or ER5556

Shielding Gas: Argon or Ar+25%He

Tungsten Inert Gas (GTAW):

Electrode: EWTh-2 (2% thorium)

Gas Flow: 12-18 L/min

Resistance Spot Welding:

Pressure: 2.5-4.0 kN

Time: 0.2-0.5 sec

Specialized Joining Methods:

Adhesive Bonding:

Epoxy structural: 15-25 MPa

Methacrylate: 12-20 MPa

Mechanical Fastening:

Self-piercing rivets

Blind rivets

Clinching technology

Brazing Systems:

Aluminum-silicon filler metals

Furnace or torch brazing

8. Physical Properties for Engineering Design

| Property | Value | Design Significance |

| Density | 2.68 g/cm³ | Lightweight advantage |

| Young’s Modulus | 70.3 GPa | Stiffness in design |

| Poisson’s Ratio | 0.33 | Stress distribution |

| CTE (20-100°C) | 23.8 μm/m·°C | Thermal expansion |

| Thermal Conductivity | 138 W/m·K | Heat transfer capability |

| Electrical Conductivity | 35% IACS | Electrical applications |

| Melting Range | 605-650°C | Processing safety margin |

| Magnetic Permeability | <1.01 | Electromagnetic neutrality |

9. Quality Control & Certification

Comprehensive Testing Protocol:

Chemical Analysis: Optical emission spectroscopy

Mechanical Testing: Batch/lot certification

Corrosion Testing:

ASTM G67 for intergranular corrosion

ASTM G85 for salt spray

Non-Destructive Testing:

Ultrasonic scanning (ASTM B594)

Eddy current examination

Surface Quality Inspection:

Visual per ASTM B209

Profilometer measurement

Certification & Compliance:

ISO 9001:2015 Quality System

AS9100 Aerospace Certification

NADCAP Special Processing

RoHS & REACH Compliance

Marine Classification: ABS, DNV, LR

FDA Compliance for food contact

10. Industrial Applications & Handling

Primary Application Sectors:

Marine components and superstructures

Transportation flooring and panels

Architectural cladding systems

Chemical processing equipment

Food & beverage processing

Electrical enclosures

HVAC ductwork

Automotive body panels

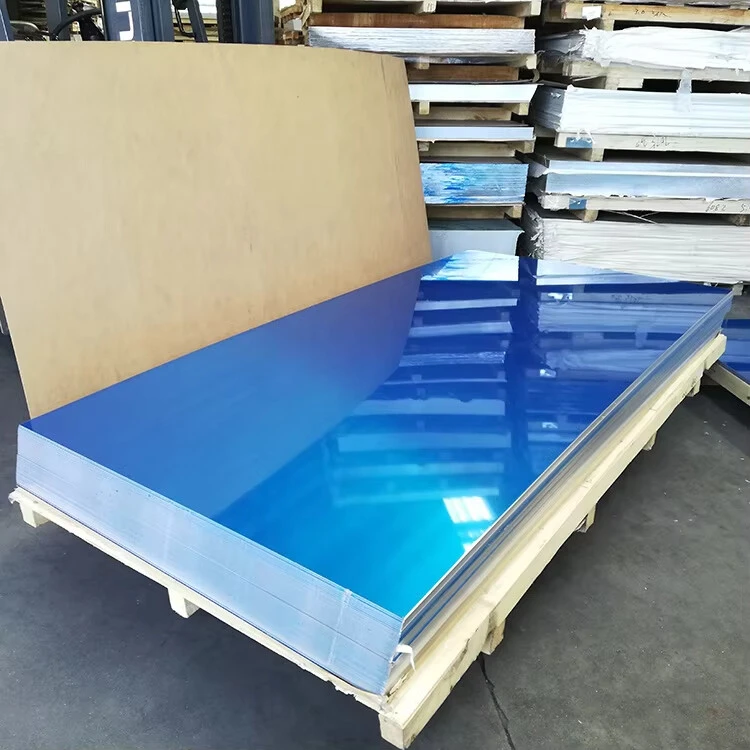

Handling & Storage Protocols:

Protective film: PE or PET coating

Storage orientation: Vertical or flat

Stacking: Wood separators every layer

Lifting: Wide belt slings (>150mm)

Environmental control: <70% humidity

Packaging: Desiccant loaded systems

Transportation Requirements:

Weatherproof covering

Edge protection systems

Non-metallic blocking

Cradle supports for plates

ISO container specifications