1. Material Composition & Manufacturing Process

5052 aluminum alloy (ASTM B209, AMS 4015) is a non-heat-treatable Al-Mg alloy optimized for exceptional corrosion resistance and good formability. The forged plate variant offers enhanced mechanical properties through controlled deformation processing:

Alloy Chemistry:

Magnesium (Mg): 2.2-2.8% (solid solution strengthening)

Chromium (Cr): 0.15-0.35% (corrosion resistance enhancer)

Iron (Fe): ≤0.40% max

Silicon (Si): ≤0.25% max

Base Material:

Aluminum (Al): ≥96.5% (balance)

Controlled Impurities:

Copper (Cu): ≤0.10% max

Zinc (Zn): ≤0.10% max

Manganese (Mn): ≤0.10% max

Specialized Forging Process:

Cast Ingot Production: 650-690°C melt temperature

Homogenization: 540-560°C for 10-18 hours

Preheating: 400-450°C for 1.5-2.5 hours

Open Die Forging:

Initial Deformation: 425-450°C

Final Passes: 350-400°C

Deformation Ratio: 3:1 to 5:1

Controlled Cooling: 30-50°C/hour to ambient

Stress Relief: 290-315°C for 1-2 hours

Precision Machining: Custom tolerances

Produced under ISO 9001:2015 quality system with full material traceability.

2. Mechanical Properties of Forged 5052 Plate

| Property | Minimum | Typical | Test Standard | Advantage Over Rolled Plate |

| Ultimate Tensile Strength | 215 MPa | 230-260 MPa | ASTM B557 | 10-15% higher strength |

| Yield Strength (Rp0.2) | 170 MPa | 180-210 MPa | ASTM B557 | Improved through-thickness properties |

| Elongation (50mm gauge) | 12% | 16-20% | ASTM B557 | Better isotropic ductility |

| Shear Strength | 140 MPa | 150-170 MPa | ASTM B769 | Enhanced edge properties |

| Fatigue Strength (10⁷) | 130 MPa | 140-150 MPa | ASTM E466 | 15-20% superior fatigue resistance |

| Hardness (Brinell) | 60 HB | 68-75 HB | ASTM E10 | Uniform hardness profile |

| Impact Energy (Charpy) | 22 J | 25-30 J | ASTM E23 | Improved toughness |

| Modulus of Elasticity | 70.3 GPa | 71-72 GPa | ASTM E111 | Consistent elastic response |

| Compressive Yield | 180 MPa | 190-215 MPa | ASTM E9 | Better bearing capacity |

3. Forging Microstructure Control

Precision Forging Parameters:

Forging Ratio (Total Reduction):

Minimum: 3:1

Optimal: 4.5:1

Maximum: 6:1

Forging Direction Control:

Multi-directional deformation

Minimum 15% reduction in secondary direction

Temperature Profile:

Starting: 425-450°C

Final: 350-380°C

Cooling Rate: Controlled air cool

Microstructural Characteristics:

Grain Size: ASTM 6-8 (20-45μm)

Grain Structure: Equiaxed with minimal elongation

Intermetallic Phases:

Al₃Fe dispersoids

Al₈Mg₅ particles (controlled size)

Dislocation Density: 5-7×10¹⁰/cm²

Recrystallization Fraction: 90-100%

Texture: Randomized crystallographic orientation

Grain Boundary Engineering: Enhanced high-angle boundaries

4. Dimensional Specifications & Tolerances

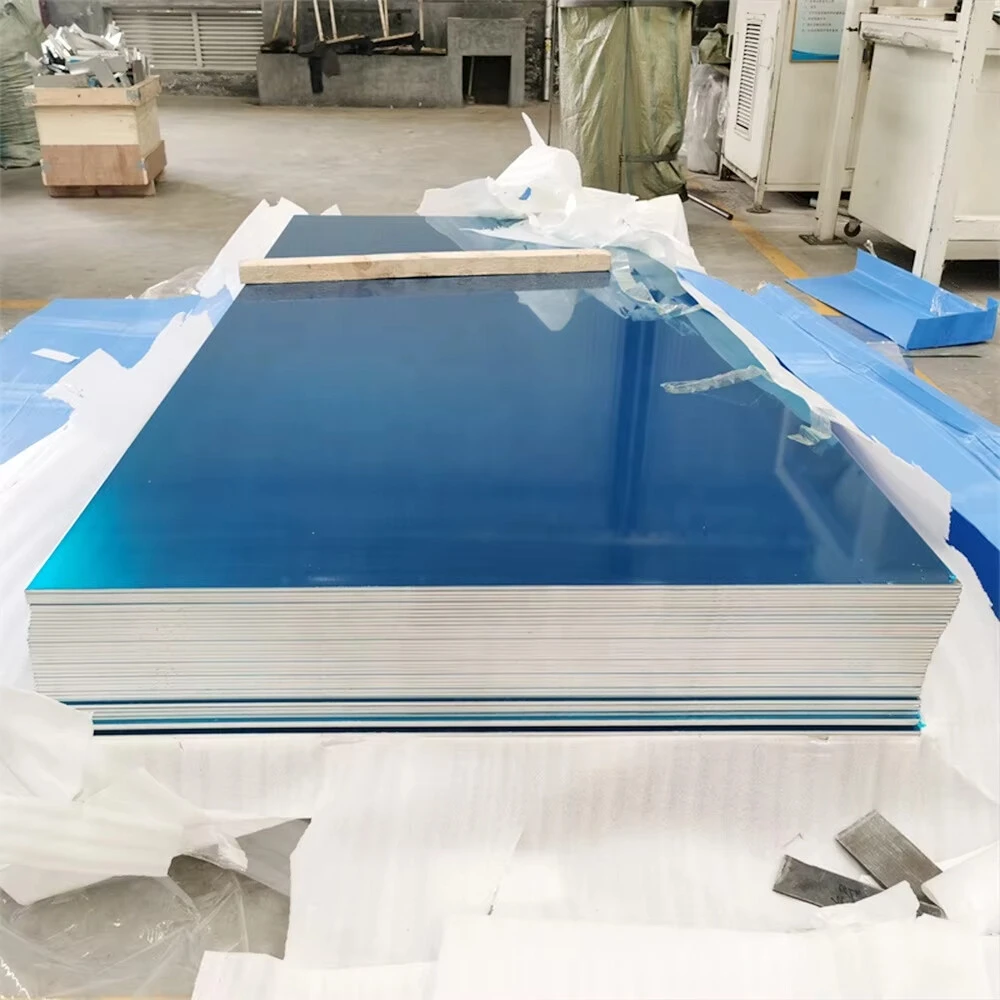

| Parameter | Standard Range | Premium Tolerance | Commercial Tolerance |

| Thickness | 10-200 mm | ±0.5 mm | ±1.0 mm |

| Width | 600-2500 mm | ±3 mm | ±5 mm |

| Length | 1000-4000 mm | ±5 mm | ±10 mm |

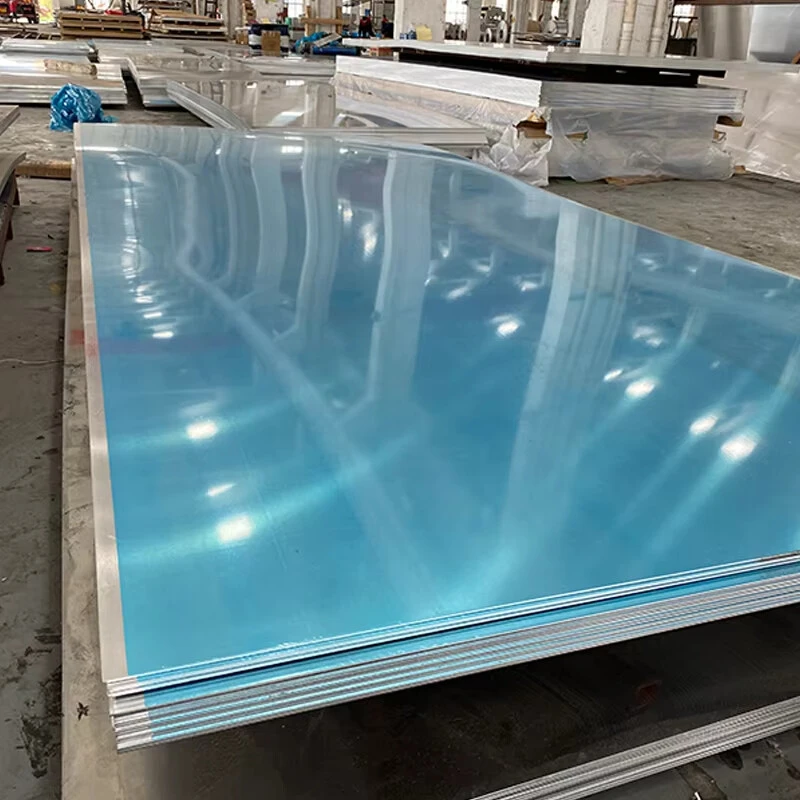

| Flatness | N/A | 0.2% of diagonal | 0.5% of diagonal |

| Surface Roughness | N/A | 3.2 μm Ra max | 6.4 μm Ra max |

| Corner Radius | 2-5 mm | ±1 mm | ±2 mm |

| Edge Straightness | N/A | 0.5 mm/m | 1.0 mm/m |

Special Capabilities:

Tapered Thickness: Up to 4:1 ratio

Contoured Surfaces: 3D profiling available

Near-Net Shape Options: Reduced machining allowance

Integral Features: Bosses, pads, and ribs possible

Weight Formula: Thickness(mm) × Width(m) × Length(m) × 2.68 = Weight(kg)

5. Corrosion Resistance Performance

| Environment | Performance | Corrosion Rate | Protection Method |

| Marine Atmosphere | Excellent | <0.05 mm/yr | Anodizing (Type II) |

| Fresh Water | Excellent | Negligible | None required |

| Salt Spray (ASTM B117) | Very Good | 1000+ hours | Chemical conversion |

| Industrial Exposure | Excellent | <0.1 mm/yr | Clear coat sealing |

| Stress Corrosion | Excellent | Immune at yield | None required |

| Galvanic Compatibility | Good | Isolation needed | Insulating washers |

| Crevice Corrosion | Good | Low tendency | Design optimization |

Surface Enhancement Options:

Anodizing:

Type II (Sulfuric): 10-25μm

Type III (Hard): 25-75μm

Boric-Sulfuric: 5-15μm

Chemical Conversion:

Chromate (MIL-DTL-5541)

Trivalent chromium

Titanium-zirconium systems

Mechanical Treatments:

Shot peening (8-12 Almen)

Brush finishing

Bead blasting

6. Machining & Fabrication Performance

| Operation | Tool Material | Recommended Parameters | Surface Quality |

| Milling | HSS-Co, Carbide | Vc=350-450 m/min, fz=0.2 mm | Ra 0.8-2.5 μm |

| Drilling | Carbide drills | Vc=80-120 m/min, fn=0.2 mm/rev | H8 tolerance |

| Turning | PCD inserts | Vc=500-800 m/min | Ra 0.4-1.6 μm |

| Tapping | HSS-E taps | Vc=15-25 m/min | Good thread profile |

| Sawing | Carbide-tipped | 60-80 m/min, 2-4 teeth engaged | Clean edge |

| Waterjet Cutting | Garnet abrasive | 3800 bar, 0.4-0.8 kg/min | ±0.1 mm tolerance |

Forming Characteristics:

Bend Radius (Minimum): 1.0t (t=thickness)

Elongation Capacity: 15-20% uniform strain

Springback Factor: 0.93-0.96

Cold Working Limit: 15-18% strain hardening

Hot Forming: 260-370°C recommended

Post-Form Treatment: None required

7. Welding & Joining Technologies

Recommended Welding Processes:

Gas Tungsten Arc Welding (GTAW):

Filler: ER5356 or ER5183

Shielding: 100% Argon

Pre-weld Cleaning: Essential

Gas Metal Arc Welding (GMAW):

Filler: ER5356

Shielding: Argon + 30% Helium

Mode: Pulse spray transfer

Friction Stir Welding (FSW):

Tool RPM: 800-1200

Feed Rate: 200-400 mm/min

Tool Material: H13 steel

Mechanical Joining Methods:

Self-Piercing Rivets: Excellent compatibility

Flow-Drill Screwing: Good for thin sections

Adhesive Bonding: Excellent with epoxy systems

Clinching: Good formability allows successful joints

Post-Weld Treatment:

Stress Relief: 175-200°C for 1 hour

PWHT: Not required (non-heat treatable)

Dressing: Recommended for fatigue applications

Inspection: Dye penetrant for critical joints

8. Physical Properties for Engineering Design

| Property | Value | Application Significance |

| Density | 2.68 g/cm³ | Lightweight structural design |

| Melting Range | 605-650°C | Process temperature limitation |

| Thermal Conductivity | 138 W/m·K | Heat sink applications |

| Electrical Conductivity | 35% IACS | Electrical enclosures |

| Specific Heat | 880 J/kg·K | Thermal management design |

| CTE (20-100°C) | 23.8 ×10⁻⁶/K | Expansion joint calculation |

| Modulus of Elasticity | 70.3 GPa | Deflection analysis |

| Poisson’s Ratio | 0.33 | FEA simulation parameter |

| Damping Capacity | 0.002-0.003 | Vibration control applications |

9. Quality Control & Certification

Testing Protocol:

Chemical Analysis: Optical emission spectroscopy

Mechanical Testing:

Full tensile test suite (L, LT, ST directions)

Hardness mapping across section

Microstructure Evaluation:

Grain size determination

Inclusion rating

Intermetallic phase analysis

Non-Destructive Testing:

Ultrasonic per ASTM B594

Dye penetrant for surface defects

X-ray for critical applications

Dimensional Inspection:

CMM verification of critical dimensions

3D laser scanning for complex geometries

Surface profile measurement

Available Certifications:

ISO 9001:2015 Quality Management

AS9100D Aerospace Standard

NORSOK M-650 for Marine Applications

NACE MR0175/ISO 15156 Compliance

PED 2014/68/EU for Pressure Equipment

Lloyd’s Register Material Certification

DNV-GL Material Approval

Material Test Certificate EN 10204 3.1/3.2

10. Industrial Applications & HandlingProducts Description

Primary Applications:

Marine components and fittings

Chemical processing equipment

Transportation structures

Food processing equipment

Architectural components

Pressure vessel nozzles and flanges

Semiconductor manufacturing equipment

Military hardware components

Valve bodies and pump housings

Railway vehicle structures

Material Handling Guidelines:

Lifting & Transport:

Use wide nylon slings

Avoid chain contact with surface

Support large plates fully

Prevent moisture accumulation

Storage Requirements:

Store in dry environment (<65% RH)

Avoid contact with steel materials

Use neutral pH packing materials

Store vertically when possible

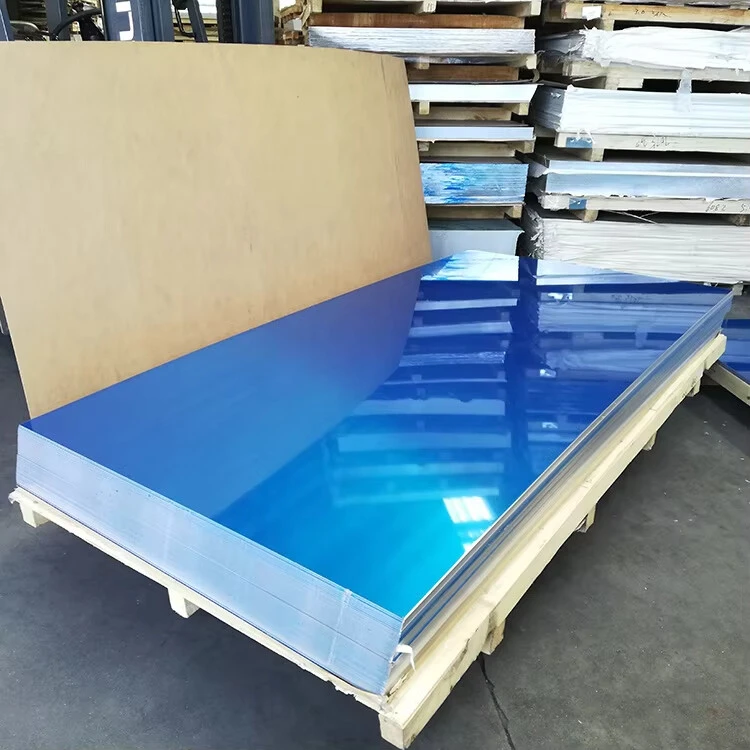

Surface Protection:

Protective film application

Interleaving with pH-neutral paper

VCI (volatile corrosion inhibitors)

Edge protectors during transport

Machining Preparation:

Acclimatize to shop temperature

Clean with non-alkaline detergents

Use dedicated aluminum tooling

Apply cutting fluid specifically for aluminum

11. Forged vs. Rolled Plate ComparisonProducts Description

Mechanical Property Advantages:

Improved through-thickness properties

Reduced directional variation (anisotropy)

Enhanced fatigue performance (15-20%)

Superior machinability and tool life

Better dimensional stability in service

Microstructural Benefits:

Refined grain structure

Reduced porosity (<0.5%)

Controlled intermetallic distribution

Minimized segregation effects

Favorable crystallographic textures

Performance Differentiators:

Higher damage tolerance

Improved stress corrosion resistance

Enhanced dynamic load capacity

Better high-temperature property retention

Superior resistance to cyclic deformation

12. Sustainability & Environmental ConsiderationsProducts Description

Material Production Metrics:

Embodied Energy: 165-180 MJ/kg

Carbon Footprint: 9.5-11 kg CO₂e/kg

Recycled Content: Up to 75% available

Water Usage: 11-15 m³/metric ton

Recyclability: 100% with no degradation

RoHS Compliance: Full compliance certified

REACH Status: No SVHC substances

Life Cycle Considerations:

Service Life: 25-40+ years in marine environments

Maintenance: Minimal requirements

End-of-Life: High scrap value and recycling efficiency

Energy Recovery: 95% energy saving vs. primary production

Disposal Impact: Non-toxic, non-hazardous classification