1. Material Composition & Manufacturing Process

2024 aluminum alloy (AMS 4035, ASTM B209, EN 485) is a high-strength Al-Cu-Mg alloy engineered for critical structural applications. The T351 temper provides optimal fracture toughness through solution heat treatment, controlled stretching, and natural aging:

Alloy Chemistry:

Copper (Cu): 3.8-4.9% (precipitation hardening)

Magnesium (Mg): 1.2-1.8% (S-phase formation)

Manganese (Mn): 0.30-0.9% (grain refinement)

Iron (Fe): ≤0.50% max

Base Material:

Aluminum (Al): ≥93.5% (balance)

Controlled Impurities:

Zinc (Zn): ≤0.25% max

Chromium (Cr): ≤0.10% max

Silicon (Si): ≤0.50% max

Precision Thermomechanical Processing:

Direct Chill Casting: 700-750°C molten temperature

Homogenization: 480-495°C for 12-24 hours

Hot Rolling: Reduction at 400-440°C

Solution Heat Treatment: 493-502°C (±3°C) for 1.5-2 hours

Water Quenching: Cooling rate >170°C/sec

Stretching: Permanent set 1.5-3% (T351 specific)

Natural Aging: 30-120 days at ambient temperature

Certified to AMS 4035 and NAS 402 specifications with full aerospace traceability from melt to plate.

2. Mechanical Properties of T351 Temper State

| Property | Minimum | Typical | Test Standard | Aerospace Significance |

| Ultimate Tensile Strength | 415 MPa | 440-480 MPa | ASTM B557 | Superior to T3 temper |

| Yield Strength (Rp0.2) | 275 MPa | 300-320 MPa | ASTM B557 | 85% retention at 150°C |

| Elongation (50mm gauge) | 8% | 10-15% | ASTM B557 | Higher in rolling direction |

| Shear Strength | 255 MPa | 285 MPa | ASTM B831 | 65% of tensile strength |

| Bearing Strength | 580 MPa | 620 MPa | ASTM E238 | e/D=2.0 condition |

| Fatigue Strength (10⁷) | 140 MPa | 160 MPa | ASTM E466 | R=0.1 condition |

| Hardness (Brinell) | 120 HB | 125-135 HB | ASTM E10 | Consistent through section |

| Fracture Toughness (K₁c) | 35 MPa√m | 40 MPa√m | ASTM E399 | L-T orientation preferred |

| Compression Yield | 275 MPa | 300 MPa | ASTM E9 | Rib/spar applications |

3. Microstructure & Thermomechanical Processing

T351 Temper Specifics:

Solution Heat Treatment:

Temperature: 495±5°C

Soak Time: 30 min/inch thickness

Quench Delay: <10 seconds

Stretching Process:

Permanent Set: 2.0-2.5%

Uniformity Tolerance: ±0.15%

Natural Aging Kinetics:

80% properties in 4 days

Full stabilization in 30 days

Microstructural Characteristics:

Grain Structure: Unrecrystallized with pancake grains

Aspect Ratio: 8-10:1 in rolling direction

Precipitate Phases:

θ’ (Al₂Cu) platelets (10-100nm)

S (Al₂CuMg) phases

Dispersoids:

Al₂₀Cu₂Mn₃ compounds

Dislocation Density: 5-8×10¹⁰/cm²

Subgrain Size: 1-3μm

4. Dimensional Specifications & Tolerances

| Parameter | Aerospace Tolerance | Commercial Tolerance | Notes |

| Thickness (3-150mm) | ±0.3% | ±0.7% | AMS 4035 Class A |

| Width (1200-3000mm) | ±3 mm | ±12 mm | Edge exclusion zone 25mm |

| Length (2400-12000mm) | +5/-0 mm | +20/-0 mm | Precision cuts available |

| Flatness | 0.2% of length | 0.5% of length | Per NAS 402 requirements |

| Squareness | 1 mm/1000 mm | 3 mm/1000 mm | Critical for spars |

| Surface Roughness | 0.4-0.8 μm Ra | 1.0-3.0 μm Ra | Mirror finish optional |

Special Capabilities:

Oversize Plates: Up to 4000mm wide × 15000mm long

Ultrasonic Inspection: ASTM B594 Level AA

Edge Conditions: Machined, sheared, or abrasive cut

Weight Formula: Thickness(mm) × Width(m) × Length(m) × 2.78 = Weight(kg)

5. Corrosion Resistance & Protection Systems

| Environment | Performance | Protection Method | Aerospace Application |

| Humidity Exposure | Fair | Alclad version recommended | Skin panels |

| Salt Spray (500hr) | Poor | Anodizing + primer required | External structures |

| Stress Corrosion | Moderate | Overaging (T851) optional | Critical load components |

| Exfoliation | Poor | Cladding essential | Wing surfaces |

| Fuel Tank Environment | Good | Integral fuel tank coatings | Wing box structures |

| Galvanic Corrosion | Fair | Isolation washers | Fastened joints |

Surface Treatment Systems:

Alclad Coating: 5-10% total thickness per side

Anodizing:

Chromic acid: 2.5-5.0μm

Sulfuric acid: 10-25μm

Primers:

Epoxy primers (8-15μm)

Chromate primers (5-8μm)

Topcoats:

Polyurethane topcoats (25-50μm)

Specialty fuel tank sealants

Chemical Conversion: Titanium-zirconium systems

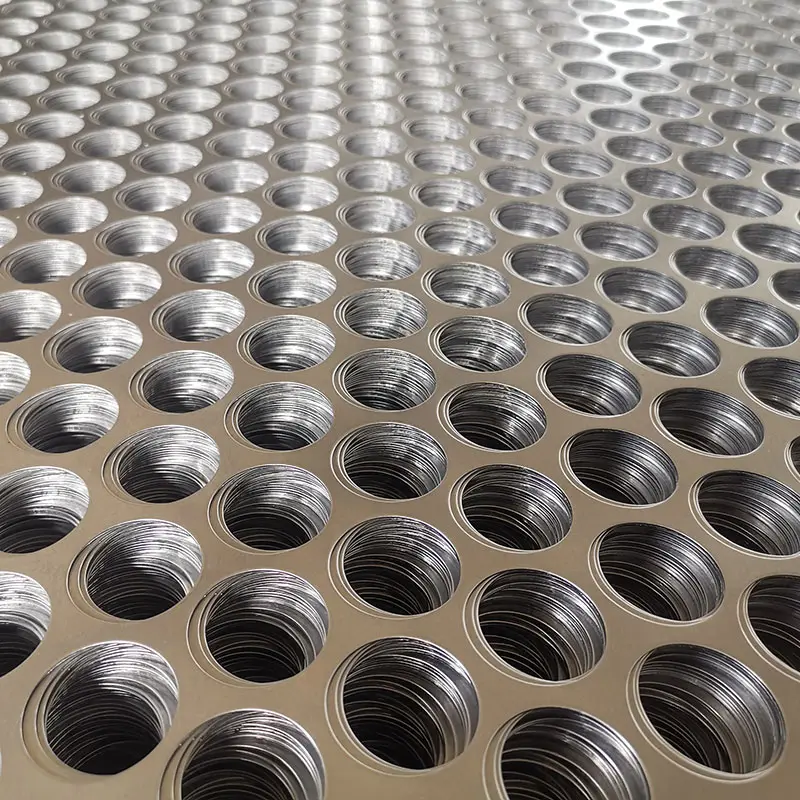

6. Machining & Fabrication Properties

| Operation | Tool Material | Recommended Parameters | Aerospace Practice |

| Milling | Carbide inserts | Vc=600-1000 m/min, fz=0.15 mm | High RPM machining |

| Drilling | Carbide drills | Vc=80-150 m/min, fn=0.1 mm/rev | Peck drilling cycle required |

| Turning | PCD/CBN tools | Vc=600-900 m/min | Dry machining feasible |

| Reaming | Coated reamers | Vc=20-30 m/min | H8 tolerance achievable |

| Grinding | CBN wheels | Vc=30-35 m/sec | Surface finish Ra 0.2μm |

| EDM | Graphite electrodes | Current: 15-30A | Precision cavity machining |

Forming Considerations:

Bend Radius: 3T minimum (T=thickness)

Springback Compensation: 2-4° overbend required

Hot Forming: 150-190°C recommended

Creep Age Forming: 120-130°C for 8-24 hours

Post-forming Heat Treatment: Prohibited in T351

7. Welding & Joining Technologies

Process Limitations:

Fusion Welding: Generally not recommended

Alternative Joining Methods:

Riveting: CherryMAX aerospace rivets

Adhesive Bonding: FM-300 film adhesive

Friction Stir Welding: Limited applications

Laser Beam Welding: Experimental only

Brazing: Vacuum furnace brazing

Repair Welding Protocol:

Material Condition: Only T351 plate

Filler Metal: 4043 or 2319 alloys

Preheat: 120-150°C mandatory

Post-Weld Aging: 120°C/24hr recommended

NDT Requirements: Dye penetrant mandatory

8. Physical Properties for Aerospace Design

| Property | Value | Flight Application Significance |

| Density | 2.78 g/cm³ | Weight-critical structures |

| Melting Range | 500-635°C | Firewall protection limits |

| Thermal Conductivity | 121 W/m·K | Heat sink components |

| Electrical Conductivity | 34% IACS | Avionics housing applications |

| CTE (20-100°C) | 22.9 ×10⁻⁶/K | Thermal stress calculations |

| Young’s Modulus | 73.1 GPa | Wing flexure modeling |

| Poisson’s Ratio | 0.33 | Finite element analysis |

| Fatigue Crack Growth Rate | 4×10⁻⁴ mm/cycle | Damage tolerance design |

| Damping Capacity | 0.001 | Vibration-sensitive components |

9. Quality Control & Certification

Testing Protocol:

Chemical Analysis: Spark OES per ASTM E1251

Mechanical Testing:

Longitudinal/transverse specimens

Tensile tests per 1000kg lot

Fracture Toughness Testing:

K₁c values for all plate shipments

Corrosion Testing:

ASSET per ASTM G66

EXCO per ASTM G34

NDT Requirements:

Ultrasonic per AMS 2631

Fluorescent penetrant inspection

Eddy current for surface flaws

Microstructure Control:

Grain size per ASTM E112

Precipitate distribution analysis

Aerospace Certifications:

AS9100 Rev D Quality System

NADCAP Accredited:

Heat Treating

Chemical Processing

NDT

MIL-Specs:

MIL-A-83377

MIL-PRF-6855

OEMS Approval: Boeing D6, Airbus AIMS

EU Aviation Safety: EASA Form 1

10. Industrial Applications & Handling

Aerospace Applications:

Aircraft fuselage skins

Wing stringers and ribs

Landing gear components

Engine mounting structures

Rotorcraft transmission platforms

Spacecraft fuel tanks

Missile airframes

Flight control surfaces

Material Handling Protocol:

Storage Conditions:

Temperature: 15-30°C

Humidity: <45% RH

Isolation from corrosive materials

Stacking Requirements:

Wooden dunnage at 300mm intervals

Maximum stack height: 800mm

Protective interleaving paper

Lifting Systems:

Vacuum pad lifters

Spread beam systems

Non-magnetic handling fixtures

Transport Precautions:

VCI (Vapor Corrosion Inhibitor) protection

Desiccant packages

Weatherproof enclosures

Post-processing:

Immediate surface cleaning

Temporary corrosion protection

Controlled aging period

Time-limited storage before use