Trying to understand the subtle yet crucial differences between roll forging and standard rolling? Both shape metal, but how they do it and the results they yield are distinct.

Roll forging uses grooved rollers to shape heated metal, gradually reducing its cross-section and increasing its length, while standard rolling involves passing flat metal sheets or plates between smooth rollers to reduce thickness.

Many of my clients, especially traders and those in machining, often inquire about different metal shaping processes. Understanding these distinctions is vital for specifying the correct material and manufacturing method for their projects.

What is the difference between rolling and forging?

When clients ask about rolling versus forging, they’re essentially asking about two different fundamental ways metal can be shaped and strengthened.

Rolling is a process that reduces the thickness of a metal workpiece by passing it between rollers, often producing flat products like sheets or bars. Forging, on the other hand, shapes metal by applying compressive forces, typically using dies, to deform it into a desired form, enhancing its internal structure.

The distinction between rolling and forging is a key concept in metalworking. While both alter the shape of metal, the underlying mechanisms and the resulting material properties are quite different. My experience has shown that understanding this difference helps clients select the most appropriate manufacturing route for their specific needs, whether it’s for structural components or custom parts.

Here’s a breakdown of the core differences:

Process Mechanism: Rolling primarily involves reducing the cross-sectional area of a metal by squeezing it between rotating rolls. Forging involves deforming the metal through impact or pressure, often within shaped dies, to achieve a specific form.

Material Structure: Rolling can alter the grain structure, but forging fundamentally refines it by aligning the grains along the direction of metal flow. This alignment significantly enhances the material’s strength, toughness, and fatigue resistance.

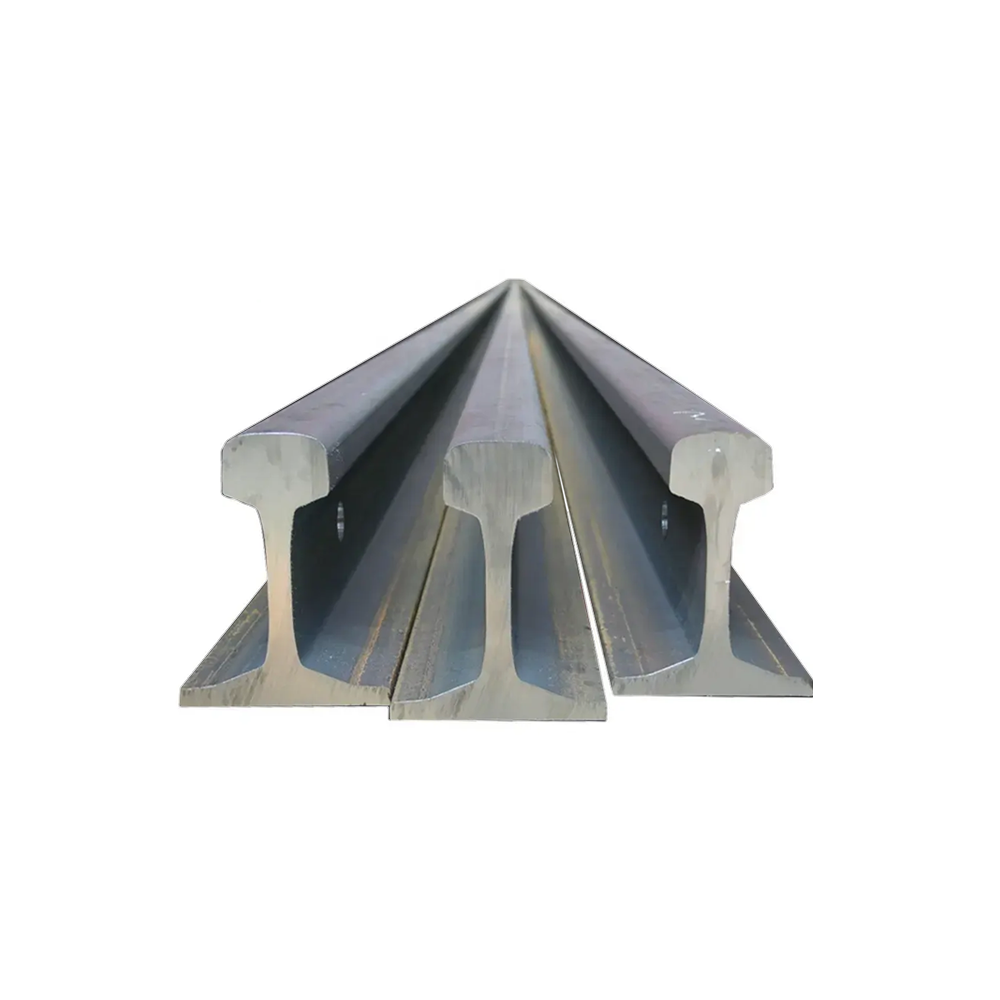

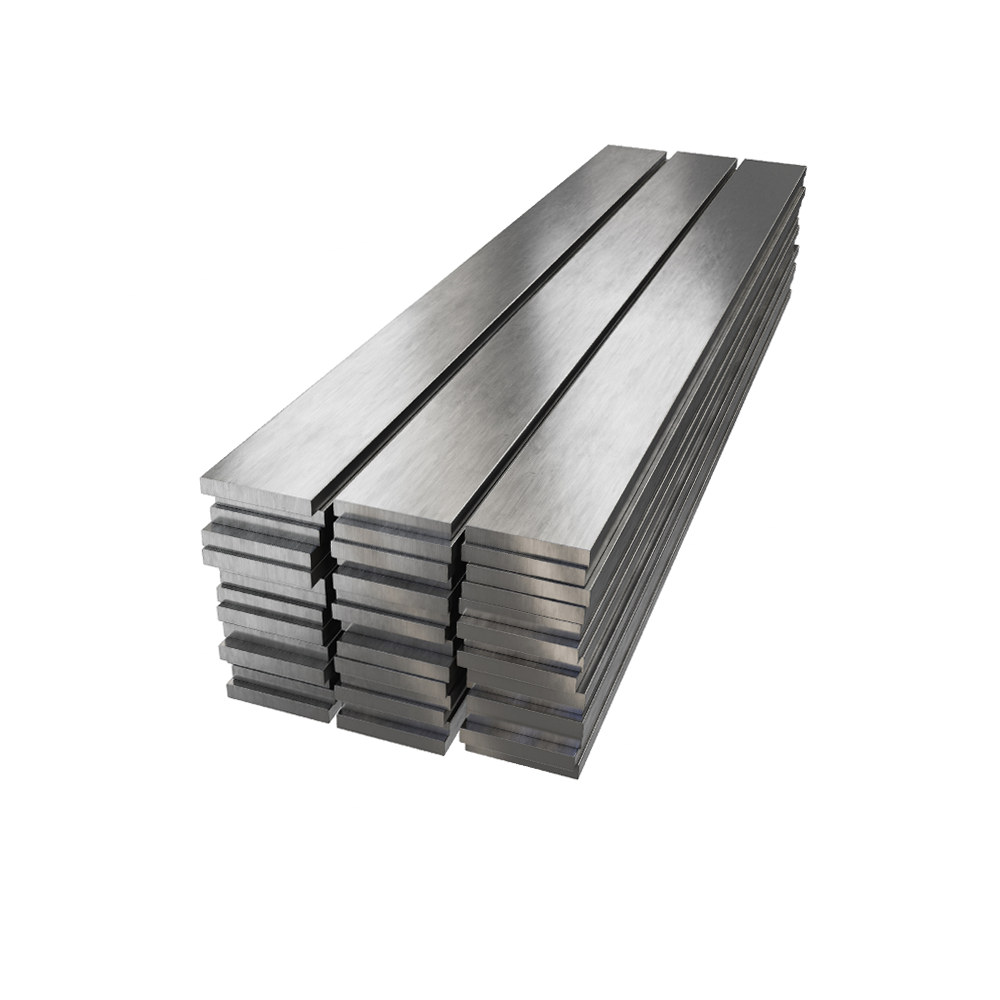

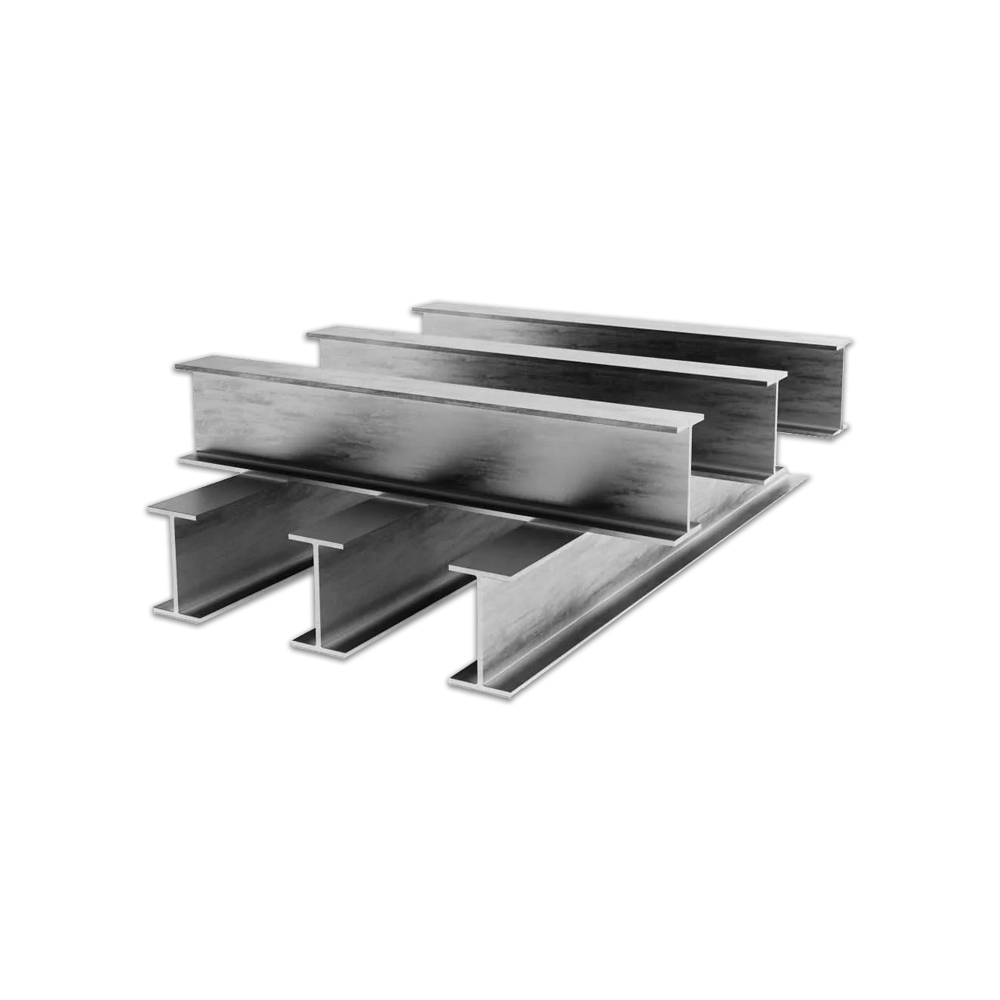

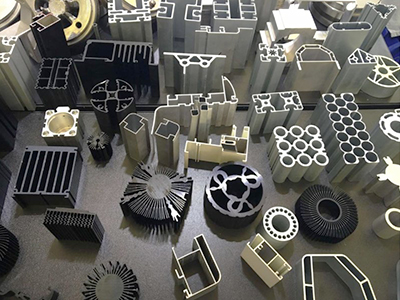

Product Forms: Rolling is often used to produce continuous products like sheets, plates, bars, and structural shapes. Forging is typically used to create discrete parts with complex shapes and precise dimensions, such as crankshafts, gears, or structural components for aerospace.

Strength and Durability: Forged parts generally exhibit superior mechanical properties (strength, toughness, wear resistance) compared to rolled parts made from the same alloy because of the refined grain structure achieved through forging.

Tooling: Rolling requires large, often smooth, cylindrical rolls. Forging uses specialized dies that conform to the desired part shape.

In essence, rolling is about reducing thickness and creating forms like sheets, while forging is about shaping and strengthening the metal, often into more complex, high-performance components.

What is the difference between rolled steel and forged steel?

The difference between rolled steel and forged steel lies in how they are manufactured and, consequently, their internal structure and performance characteristics.

Rolled steel is formed by passing heated steel through rollers to reduce its thickness or shape it, while forged steel is shaped by applying compressive forces, often using dies, which refines its grain structure for superior strength, toughness, and fatigue resistance.

Clients often want to know why one steel product might be “forged” and another “rolled.” The answer impacts performance significantly. Understanding this difference is crucial for selecting the right material for demanding applications where strength and reliability are paramount.

The key distinctions are:

Grain Flow: This is the most critical difference. In rolled steel, the grain structure follows the rolling direction, which can lead to directional properties. In forged steel, the grain structure follows the contours of the part, providing uniform strength and resistance to stress from all directions.

Strength and Toughness: Forged steel typically has higher tensile strength, yield strength, and toughness compared to rolled steel of the same grade. This is due to the refined grain structure and the absence of defects that can sometimes be introduced during rolling.

Mechanical Properties: Rolled steel’s properties can be more anisotropic (direction-dependent). Forged steel generally exhibits more isotropic properties, meaning its strength is more uniform regardless of the direction of applied stress.

Defect Reduction: The forging process tends to eliminate internal voids and imperfections present in the original ingot or billet. Rolling, while it can reduce defects, may sometimes elongate them in the direction of rolling.

Applications: Rolled steel is common for structural elements, sheets, plates, and rails where uniform strength in a specific direction is acceptable or desired. Forged steel is used in high-stress applications like aircraft components, automotive engines, and heavy machinery parts where exceptional strength, durability, and reliability are critical.

For applications requiring the highest levels of strength and performance, forged steel is generally the preferred choice.

What are the advantages of roll forging?

Roll forging, a specific type of forging, offers unique benefits that make it ideal for certain manufacturing needs, particularly for creating symmetrical parts.

The advantages of roll forging include its efficiency in reducing the cross-section of heated metal blanks, its ability to create symmetrical parts with uniform grain flow, and its cost-effectiveness for high-volume production of components like shafts and axles.

Roll forging is a specialized process that offers significant advantages when the goal is to shape symmetrical parts efficiently. For my clients, understanding these benefits helps them see how this method can be applied to their specific product requirements, especially when high volume and consistent quality are key.

Here are the main advantages of using roll forging:

Efficient Cross-Section Reduction: Roll forging is highly effective at reducing the cross-sectional area of a heated metal bar or billet. The rotating dies can work the metal progressively, making it more pliable for subsequent shaping steps.

Uniform Grain Structure: Similar to other forging processes, roll forging aligns the metal’s grain structure along the contours of the die impressions. This results in superior mechanical properties, including increased strength, toughness, and fatigue life, distributed evenly throughout the part.

Cost-Effectiveness for High Volumes: For parts that are symmetrical or can be formed in segments, roll forging can be very cost-effective. The process is relatively fast, and the tooling can be designed for high-volume production runs.

Improved Material Yield: By gradually shaping the metal, roll forging often leads to better material utilization and less waste compared to some other forming processes.

Creating Specific Shapes: It’s particularly useful for creating parts with variations in diameter along their length, such as shafts, axles, and connecting rods, which often require precise dimensional control.

These advantages make roll forging a valuable technique for manufacturing critical components in industries ranging from automotive to general machinery.

What are the two main types of forging?

Understanding the fundamental classifications of forging helps to grasp the breadth of this metal-shaping technique and its applicability.

The two main types of forging are open-die forging and closed-die forging (also known as impression-die forging). These categories are distinguished by the design of the dies used and how the metal is contained and shaped during the process.

When discussing forging, it’s essential to start with its two primary classifications: open-die and closed-die. These categories represent fundamentally different approaches to shaping metal, each with its own set of advantages and applications. As SWA Forging, we utilize both to meet a wide array of client needs.

Let’s look at each type:

Open-Die Forging:

Description: In open-die forging, the workpiece is deformed between dies that do not completely enclose the metal. The dies usually have simple shapes, like flat surfaces or slight indentations.

Process: The heated metal is placed on the bottom die, and the top die is brought down to compress and shape it. The operator can manipulate the workpiece (rotate, move it) between blows to achieve the desired form.

Characteristics: This method is very versatile for producing custom or one-of-a-kind parts, as well as for preliminary shaping. It’s suitable for large parts and allows for significant changes in cross-section.

Typical Products: Shafts, rings, discs, flanges, bars, and large structural components.

Closed-Die Forging (Impression-Die Forging):

Description: In closed-die forging, the dies contain impressions (cavities) that match the desired final shape of the part. The heated metal is placed between these dies, and the tooling completely encloses the metal during deformation.

Process: The metal is forced to flow into the impression cavities of the dies. Excess metal is squeezed out around the edges as “flash,” which is later trimmed. This process often requires multiple die sets to gradually form the part.

Characteristics: This method is used for mass production of parts with complex shapes and tight tolerances. It offers excellent strength and uniformity due to precise grain flow.

Typical Products: Crankshafts, connecting rods, gears, automotive components, aerospace parts, and tools.

Both open-die and closed-die forging are crucial in manufacturing, each serving different purposes and production scales, ultimately providing strong, reliable metal components.