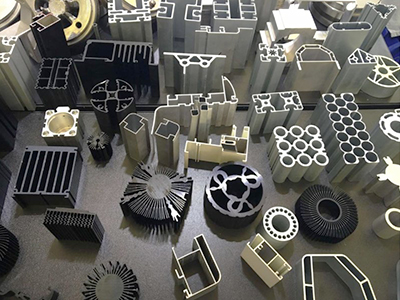

When the geometric complexity, strength requirements, or performance demands of your project exceed the capabilities of standard aluminum tubes, SWA Forging’s custom-forged aluminum rings and discs provide integrated, high-strength solutions with optimized material properties.

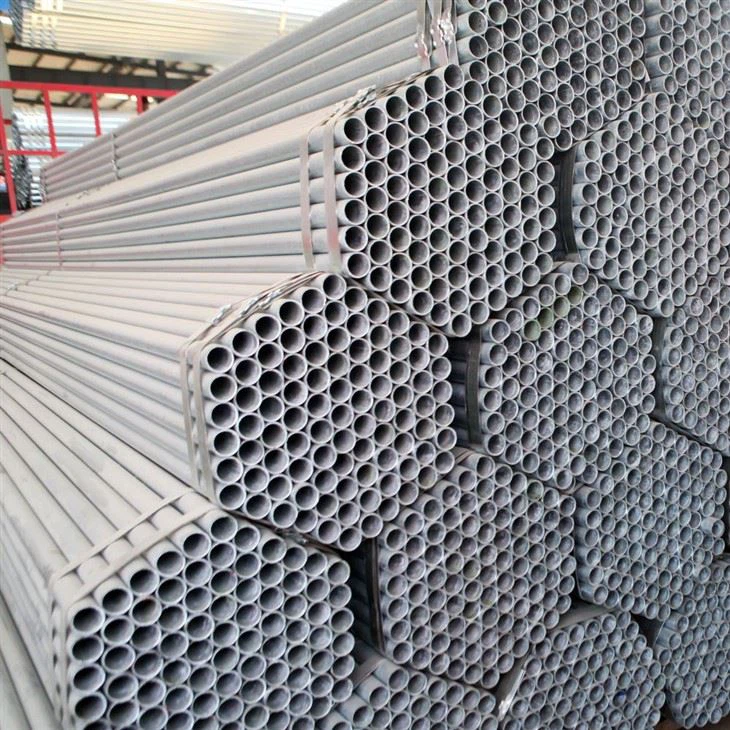

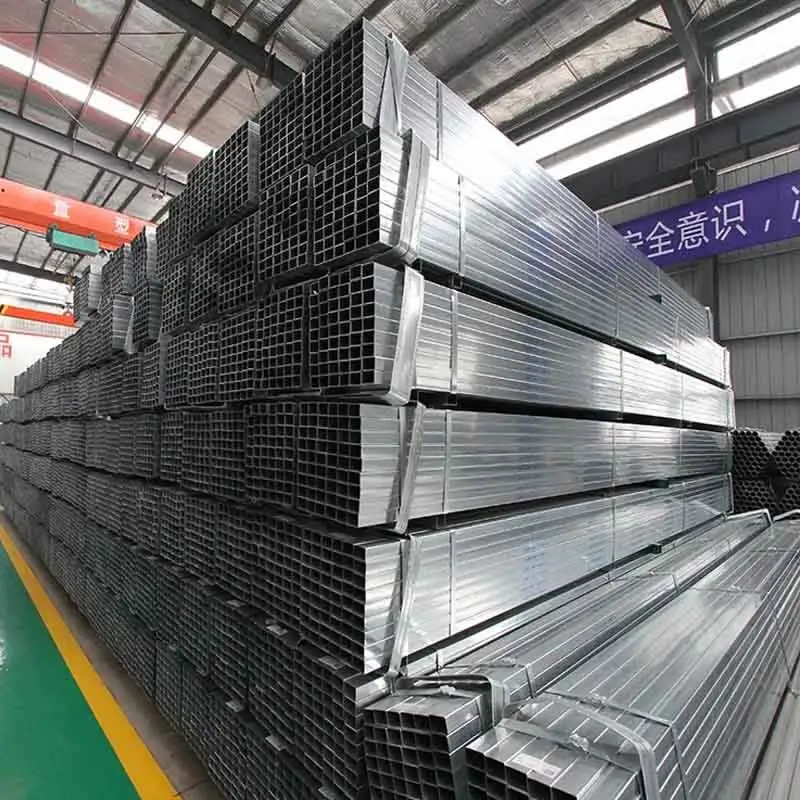

Many clients come to SWA Forging initially considering standard aluminum tubes. These are versatile components used across a vast range of industries. They are fundamental in applications like fluid transport (hydraulics, pneumatics, fuel lines), structural components (frame elements in furniture, vehicles, or machinery), heat exchangers, and conduits for electrical wiring or cables. Their hollow, cylindrical shape offers a good strength-to-weight ratio, making them efficient for many structural and fluid-carrying purposes. However, the limitations become apparent when a project demands intricate shapes, superior load-bearing capacity in complex stress paths, or integrated functionalities that cannot be achieved through simple machining of a tube. For instance, creating a component with precise internal contours for improved fluid dynamics, or a ring with integrated mounting features that must withstand high pressures uniformly, is often beyond the scope of what standard tubes can efficiently provide. This is precisely where SWA Forging’s expertise in custom forging of aluminum rings and discs becomes invaluable, offering solutions that deliver enhanced performance and design freedom.

What are aluminum tubes used for?

Aluminum tubes are widely utilized across many industries due to their lightweight nature, corrosion resistance, and ease of fabrication, serving diverse functional roles.

Aluminum tubes are primarily used for fluid conveyance, structural framing, heat transfer applications, and as protective conduits. Their excellent strength-to-weight ratio and resistance to corrosion make them ideal for everything from automotive fuel lines and aerospace hydraulic systems to furniture frames, bicycle tubing, and heat exchangers.

For our clients at SWA Forging, understanding the broad applications of aluminum tubes helps them appreciate why custom-forged alternatives are sometimes necessary. In the automotive sector, aluminum tubing is crucial for fuel lines, brake lines, and air conditioning systems, where its lightweight nature contributes to fuel efficiency and its corrosion resistance ensures longevity. In aerospace, they are vital for hydraulic systems, fuel lines, and structural components within the aircraft fuselage and wings, where reliability and weight savings are paramount. In construction and industrial settings, aluminum tubes serve as framing for structures, supports, and enclosures, valued for their strength and ease of assembly. They are also integral to heat exchangers in HVAC systems and radiators because of aluminum’s excellent thermal conductivity. Even in everyday items like bicycles and furniture, aluminum tubing provides the necessary strength and lightness. However, when specific shapes, very high pressures, or complex load-bearing requirements are involved, the standard tube’s limitations often lead clients to consider our custom forged solutions for enhanced performance.

Common uses of aluminum tubes:

Fluid Transport: Fuel lines, hydraulic lines, pneumatic lines, coolant lines.

Structural Components: Frames for vehicles, furniture, machinery, architectural elements.

Heat Exchange: Radiators, heat sinks, intercoolers.

Conduits: Electrical wiring protection, cable management.

Sporting Goods: Bicycle frames, hockey sticks, camping equipment.

Their versatility makes them a fundamental material in modern manufacturing.

What is the best Aluminium tube for bending?

The best aluminum alloy for bending depends on the desired bend radius and the complexity of the bend, with alloys offering a good balance of strength and ductility being preferred.

For applications requiring smooth, tight bends without kinking or cracking, aluminum alloys from the 6000 series, particularly 6061-T6, are generally considered the best for bending. This alloy offers a favorable combination of strength and ductility, allowing it to deform effectively without compromising its structural integrity.

When our clients at SWA Forging consider applications where aluminum tubing needs to be bent, the choice of alloy is critical for successful fabrication. Bending aluminum tubing involves stretching the outer radius and compressing the inner radius of the bend. If the alloy is too brittle, it can crack on the outer radius. If it’s too soft, it might collapse or kink on the inner radius, especially for tighter bends. The 6061-T6 alloy is highly recommended because its tempering provides a good level of strength, preventing collapse, while still retaining enough ductility to be formed without fracturing, especially when proper bending techniques and tooling are used. Other alloys, like the stronger 7075, can be more challenging to bend to tight radii without defects due to their lower ductility. For less demanding bends or applications where strength is less critical, alloys like 3003 or 5052 might also be suitable, offering good formability. However, for a reliable balance that works across many applications requiring significant bending, 6061-T6 is typically the preferred choice, which is why we often use it as a base for our forged components when similar properties are needed but with enhanced structural integrity.

Best aluminum alloys for bending:

6061: Excellent balance of strength and ductility, making it ideal for most bending applications.

3003: Softer and more ductile than 6061, making it easier to bend but less strong.

5052: Offers good corrosion resistance and formability, suitable for moderate bending.

7075: Very strong but less ductile, requiring careful bending techniques and tooling for tighter radii.

Proper technique and the right alloy are key to successful tube bending.

How to connect two aluminum tubes together?

Connecting aluminum tubes can be achieved through various methods, depending on the application’s requirements for strength, sealing, and aesthetics.

The most common methods for connecting aluminum tubes include welding (TIG or MIG), using mechanical fasteners like bolts and rivets with appropriate fittings or flanges, employing compression fittings or flare fittings for fluid systems, or using specialized adhesives and bonding agents for lighter-duty or vibration-dampened connections.

When clients at SWA Forging are designing systems that might involve multiple aluminum components, they often ask about connecting them. The best method depends heavily on the intended use. For structural applications requiring high strength and a permanent, robust connection, welding is often preferred. TIG (Tungsten Inert Gas) welding is typically used for aluminum due to its precision and clean finish, provided the correct filler material and technique are employed. MIG (Metal Inert Gas) welding is faster and can be used for thicker sections. For applications that need to be disassembled or where welding is not feasible, mechanical connections are used. This can involve drilling holes and using bolts with nuts, often in conjunction with flanges or special connectors that fit over or into the tube ends. Compression fittings are excellent for fluid lines, creating a seal by compressing a ferrule onto the tube. Flare fittings involve creating a cone-shaped flare on the tube end, which is then compressed against a matching fitting. For less critical or aesthetically driven connections, specialized industrial adhesives can create strong bonds, especially when combined with mechanical interlocking features. Our forged rings and discs often feature integrated connection points or flanges, simplifying assembly and ensuring strength.

Methods for connecting aluminum tubes:

Welding: TIG or MIG welding for strong, permanent joints.

Mechanical Fasteners: Bolts, rivets, used with flanges or connecting sleeves.

Compression Fittings: Ideal for plumbing and fluid lines, creating a reliable seal.

Flare Fittings: Used in high-pressure fluid systems, forming a metal-to-metal seal.

Adhesives/Bonding: For lightweight, non-structural, or vibration-sensitive applications.

The choice is dictated by strength, sealing needs, and maintenance requirements.

How do we select the proper aluminum alloy for structural repairs?

Selecting the right aluminum alloy for structural repairs is critical to ensure the repair matches the original material’s properties for strength, ductility, and corrosion resistance.

To select the proper aluminum alloy for structural repairs, you must first identify the original alloy of the component being repaired. Matching the alloy composition and temper is crucial, prioritizing strength and ductility characteristics that are compatible with the original material to avoid stress concentrations and ensure the integrity of the repair.

At SWA Forging, we understand that the integrity of aluminum structures relies on material compatibility. When performing structural repairs, especially on critical components that have been precision-forged or machined, selecting the correct aluminum alloy is non-negotiable. The first step is always to accurately identify the original alloy and its temper. This is often done through material testing, spectrographic analysis, or by checking original specifications if available. If the original alloy is known, the repair should ideally use the same alloy and temper. For example, repairing a component made of 6061-T6 with a weaker 3000 series alloy or a different temper of 6061 could create a weak point or stress riser, compromising the entire structure. If the original alloy is unknown or unavailable, one must select a repair alloy that closely matches the mechanical properties, particularly yield strength and elongation (ductility), of the original material. Using an alloy with significantly lower strength can lead to failure at the repair site, while using one that is too brittle might cause cracking. For welding repairs, specific welding filler alloys are also chosen based on compatibility with the base metal to maintain strength and corrosion resistance. Our forged components are engineered from specific alloys, ensuring predictable performance and repairability.

Key considerations for selecting repair alloys:

Identify Original Alloy: Crucial for compatibility in strength and properties.

Match Temper: Ensures the hardness and strength are consistent.

Strength Compatibility: Repair material should not be significantly weaker.

Ductility Compatibility: Avoid materials that are too brittle, which can cause cracking.

Corrosion Resistance: Repair material should offer comparable resistance to the environment.

Weldability: If welding is used, choose a filler alloy compatible with the base metal.

Accurate material identification and selection are vital for successful and safe repairs.