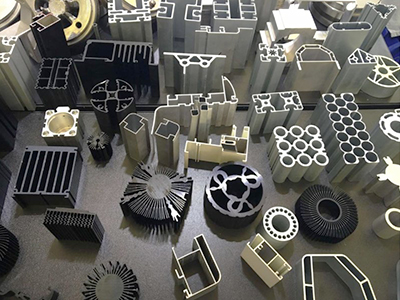

Aluminum solution heat treatment furnaces are highly specialized industrial ovens designed to precisely control the heating of aluminum alloys to a specific elevated temperature, ensuring that alloying elements dissolve uniformly into the aluminum matrix. These furnaces are characterized by their ability to maintain tight temperature uniformity, rapid heat transfer, and often, rapid quenching mechanisms integrated or positioned nearby, which are critical for achieving the desired metallurgical changes and optimal mechanical properties in heat-treatable aluminum alloys.

At SWA Forging, our solution heat treatment furnaces are central to our quality assurance. They allow us to precisely control the initial stages of strengthening our forged aluminum components, ensuring they meet the stringent material specifications demanded by our global clients.

What Is the Solution Heat Treatment for Aluminum?

Are you wondering about the initial and most critical step in strengthening heat-treatable aluminum alloys? It’s a precise thermal process that prepares the material for further property enhancement.

Solution heat treatment (SHT) for aluminum is the first stage of the precipitation hardening process, where an aluminum alloy is heated to a precise high temperature below its melting point and held there long enough for all soluble alloying elements to dissolve completely into the aluminum matrix, forming a homogeneous solid solution. This step is essential to create the supersaturated condition necessary for subsequent strengthening during quenching and aging.

Every time we perform a solution heat treatment, I emphasize the importance of hitting the exact temperature and holding time. It lays the groundwork for all the strength our customers expect.

The Purpose and Process of SHT

Solution heat treatment is not just about heating aluminum; it’s a meticulously controlled scientific process:

Purpose:

Dissolve Alloying Elements: The primary goal is to take the various alloying elements (like copper, magnesium, silicon, zinc) that are present in the aluminum alloy and get them to dissolve completely into the aluminum crystal structure. At room temperature, these elements often exist as distinct intermetallic compounds within the aluminum matrix.

Create Homogeneous Solution: By dissolving these elements, the material becomes a uniform, single-phase solid solution. This is crucial because it distributes the strengthening elements evenly throughout the material.

Prepare for Strengthening: This dissolved state is a “supersaturated” condition when cooled rapidly. This supersaturated state is inherently unstable, and the alloying elements will later precipitate out in a controlled manner during the aging step, leading to significant strengthening.

Process Steps:

Heating: The aluminum parts are placed in a specialized furnace and heated to a specific temperature. This temperature is critical – it must be high enough to dissolve the alloying elements but below the alloy’s solidus temperature (the temperature at which melting begins) to prevent incipient melting and grain boundary issues. Typical temperatures range from 450°C to 550°C (840°F to 1020°F), depending on the specific alloy.

Soaking: Once the desired temperature is reached, the parts are held at this temperature for a specific period, known as the “soak time.” The soak time depends on the alloy composition, section thickness, and the type of furnace. It must be long enough to ensure complete dissolution of the alloying elements. For thin sections, this might be minutes; for thick forgings, it could be several hours.

Uniformity: Maintaining uniform temperature throughout the load is paramount. Hot spots can cause melting, while cold spots lead to incomplete dissolution and reduced properties. Furnaces designed for SHT often have powerful air circulation systems to ensure this uniformity.

Rapid Transfer: Immediately after the soak, the material must be rapidly transferred to a quenching medium. Any delay can lead to undesirable precipitation and a significant loss of final properties.

| Stage of SHT | Key Action | Why it’s done | Critical Parameters |

| Heating | Raise temperature to specific set point | Enable dissolution of alloying elements | Rate of heating, maximum temperature |

| Soaking | Hold at set temperature for prescribed time | Ensure complete and uniform dissolution | Soak temperature, soak time |

| Transfer | Rapidly move from furnace to quench medium | Prevent premature precipitation, retain supersaturated state | Transfer speed |

I once witnessed a situation where an SHT furnace experienced a brief power fluctuation during a soak cycle. Even though the temperature dip was minimal, the subsequent material testing showed a noticeable reduction in strength for that batch. It taught me just how sensitive this process is and why precise temperature control is non-negotiable.

How Do You Heat Treat 6061 Aluminum Solution?

Are you interested in the precise steps involved in performing solution heat treatment on 6061 aluminum, a crucial part of achieving its strong T6 temper? It requires careful adherence to specific parameters.

To heat treat 6061 aluminum for solution, you heat it to a temperature range of approximately 520°C to 540°C (968°F to 1004°F) and hold it at that temperature for a specified soak time, which depends on the material’s thickness. This process allows the magnesium and silicon to dissolve into the aluminum matrix, preparing the alloy for subsequent rapid quenching and artificial aging to achieve its desired T6 strength.

For our 6061 forgings at SWA, getting the solution heat treatment right is the first step in ensuring they can withstand the demanding applications our clients have in mind.

Steps for 6061 Solution Heat Treatment

The solution heat treatment of 6061 aluminum is a critical precursor to its subsequent strengthening through artificial aging (to achieve T6 temper). Here’s how it’s typically performed:

Pre-Treatment (Optional but Recommended):

Cleaning: Ensure the 6061 parts are clean and free of oils, grease, or other contaminants. These can vaporize during heating and potentially cause surface defects or interfere with heat transfer.

Loading: Load the parts into the furnace in a way that allows for uniform heat distribution and easy, rapid removal for quenching. Avoid stacking parts too densely.

Heating:

Furnace Type: Use a furnace with excellent temperature uniformity and control, typically an air-circulating furnace (convection oven) to ensure heat reaches all surfaces evenly.

Target Temperature: Heat the 6061 aluminum to a temperature range of 520°C to 540°C (968°F to 1004°F). The most common and recommended temperature is often cited as 530°C (985°F). It’s crucial not to exceed the upper limit of this range, as incipient melting can occur, leading to permanent damage and reduced properties.

Soaking:

Hold Time: Once the entire part reaches the target temperature, hold it at that temperature for a specific period. The soak time depends primarily on the thickest section of the part:

Sheet/Thin sections: 10 minutes to 1 hour.

Thicker sections (e.g., plates, forgings): Approximately 1 hour per inch of thickness. For very large or complex parts, this could extend to several hours. The goal is to ensure complete dissolution of the Mg2Si precipitates throughout the material.

Rapid Transfer:

Minimize Delay: Immediately upon completion of the soak time, the 6061 parts must be transferred from the hot furnace to the quenching medium as quickly as possible.

Maximum Transfer Time: For 6061, the transfer time should ideally be less than 10-15 seconds. Any longer delay can cause “quenching delay precipitation,” where the dissolved elements start to precipitate out in an uncontrolled manner, reducing the effectiveness of the subsequent artificial aging and ultimately lowering the strength.

Quenching:

Medium: Quench the material in cold water (room temperature or colder). This rapid cooling locks the alloying elements in a supersaturated solid solution. For some applications, polymer quenchants may be used to reduce distortion, but this can sometimes slightly compromise mechanical properties.

The precise control over temperature and time, especially during transfer to the quench, is what ensures that the 6061 alloy reaches its full strength potential after subsequent artificial aging. When we produce large 6061 forged rings, this solution heat treatment is a highly automated and closely monitored process to guarantee consistent quality.

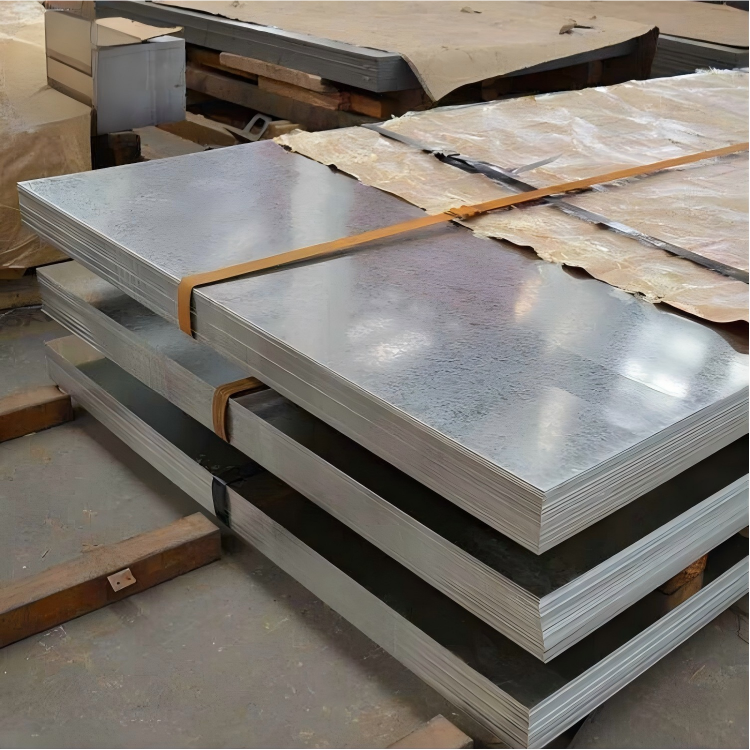

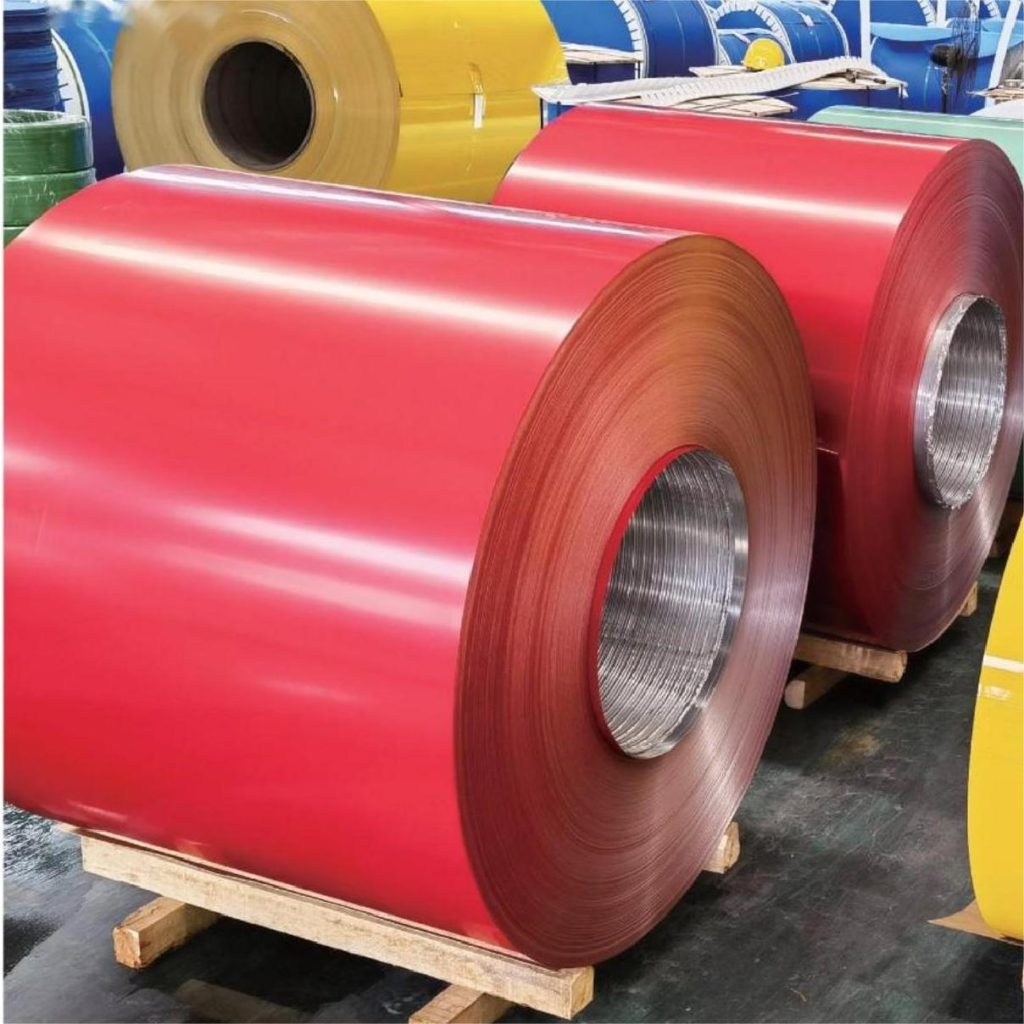

What Is the Heat Treatment for Aluminum Sheets?

Are you curious about how aluminum sheets, which are vital for everything from beverage cans to aircraft skins, undergo heat treatment to achieve their specific properties? It’s a tailored process depending on the alloy type.

The heat treatment for aluminum sheets varies significantly based on whether the alloy is heat-treatable (like 2xxx, 6xxx, 7xxx series) or non-heat-treatable (like 1xxx, 3xxx, 5xxx series). For heat-treatable sheets, it involves solution heat treatment, rapid quenching, and subsequent aging to increase strength. For non-heat-treatable sheets, heat treatment primarily consists of annealing to soften the material and relieve stresses, or stabilization heat treatments to prevent age softening in some cases.

While SWA Forging specializes in larger forged components, the principles of heat treating sheets are familiar, as many of our clients integrate our forgings into assemblies made from various sheet materials.

Heat Treatment Categories for Aluminum Sheets

The approach to heat treating aluminum sheets depends entirely on their alloy designation:

Heat-Treatable Alloys (e.g., 2xxx, 6xxx, 7xxx Series):

Purpose: To significantly increase strength, hardness, and often fatigue resistance.

Process:

Solution Heat Treatment (SHT): Sheets are heated in a furnace to a specific temperature (e.g., 460-530°C or 860-985°F, depending on the alloy) and soaked to dissolve alloying elements. For sheets, continuous furnaces are often used, where the sheet passes through heated zones.

Quenching: Immediately after SHT, the sheets are rapidly cooled. For thin sheets, this can be done by air blast, water spray, or immersion. The speed is critical to trap the dissolved elements.

Aging:

Natural Aging (T4 temper): For some alloys (e.g., 2024-T4), significant strengthening occurs spontaneously at room temperature over several days.

Artificial Aging (T6, T7, T8 tempers): Sheets are reheated to a lower, intermediate temperature (e.g., 120-200°C or 250-390°F) for several hours to accelerate precipitation hardening. This is common for 6061-T6 and 7075-T6.

Considerations: Distortion can be a significant issue with thin sheets during quenching. Techniques like roller quenching or stretch forming after quenching but before aging are used to minimize this.

Non-Heat-Treatable Alloys (e.g., 1xxx, 3xxx, 5xxx Series):

Purpose: These alloys cannot be strengthened by heat treatment in the same way heat-treatable alloys can. Their strength is primarily achieved through work hardening (cold working, indicated by H tempers like H14, H32) or solid solution strengthening. Heat treatment for these alloys usually means softening or stabilization.

Process:

Annealing (O temper): This is the most common heat treatment for non-heat-treatable sheets. Sheets are heated to a specific temperature (e.g., 340-415°C or 650-780°F) and slowly cooled. This softens the material, removes internal stresses from prior cold working, and improves ductility and formability. It’s used when a soft, formable sheet is required, or as an intermediate step during severe forming operations.

Stabilization (H3x temper): For certain 5xxx series alloys, a low-temperature thermal treatment is performed after work hardening to stabilize mechanical properties and prevent age softening or susceptibility to stress corrosion cracking over time. This is typically done at temperatures around 120-175°C (250-350°F) for a few hours.

| Alloy Type | Primary Heat Treatment Goal | Common Processes | Resulting Properties (Sheets) |

| Heat-Treatable | Maximize strength, hardness | Solution HT, Quenching, Artificial Aging (or Natural) | High strength, good hardness, reduced ductility |

| Non-Heat-Treatable | Soften, improve formability, relieve stress | Annealing | Low strength, high ductility, good formability |

| Stabilize properties | Stabilization (for H3x tempers) | Stable properties, enhanced corrosion resistance |

The choice of heat treatment for aluminum sheets is fundamentally driven by the desired end-use properties and the alloy’s specific metallurgical characteristics. It’s a sophisticated process vital for producing reliable and high-performance aluminum products.

What Is Solution Treatment in Heat Treatment?

Are you looking for a general understanding of “solution treatment” as a core concept in the broader field of heat treatment, not just for aluminum? It’s a foundational process for many alloys.

Solution treatment, or solution annealing, in heat treatment is a high-temperature process applied to certain alloys (including many aluminum, stainless steel, and nickel alloys) where the material is heated to a temperature high enough to dissolve one or more of its alloying elements into a solid solution. The material is then typically rapidly quenched to “trap” these elements in solution, creating a supersaturated state that is then amenable to subsequent strengthening processes like precipitation hardening.

In my work with aluminum, solution treatment is the critical first step. It’s the process where we prepare the material’s internal structure to unleash its full strength potential later.

The Universal Principle of Solution Treatment

Solution treatment is a powerful metallurgical tool used across various alloy systems, not just aluminum. Its fundamental principle remains consistent:

The Concept of Solid Solution:

Imagine a metal (the solvent, e.g., aluminum) with other elements (the solutes, e.g., copper, magnesium, silicon) mixed into it.

At room temperature, these solute elements might form distinct, separate phases or compounds within the main metal structure. These phases can be hard and brittle or might not contribute effectively to strengthening.

When heated to a sufficiently high temperature (but below the melting point), these solute atoms become more mobile and can dissolve into the main metal’s crystal lattice, forming a single, homogeneous “solid solution.” Think of it like sugar dissolving completely in hot water.

Steps of Solution Treatment (General):

Heating: Raise the alloy to a specific, high temperature. This temperature is carefully chosen based on the alloy’s phase diagram to ensure maximum dissolution of the soluble elements.

Soaking: Hold the alloy at this temperature for a sufficient “soak time.” This ensures that the diffusion process allows for complete dissolution and homogenization throughout the material, especially for thicker sections.

Quenching: Rapidly cool the material. This is a critical step. The rapid cooling rate prevents the dissolved solute atoms from “falling out” of solution in a coarse, uncontrolled way. Instead, they are trapped in a supersaturated solid solution. This supersaturated state is thermodynamically unstable.

Why it’s Done:

Precursor to Age Hardening: For alloys that undergo precipitation hardening (like many aluminum alloys, maraging steels, some stainless steels), solution treatment is absolutely essential. The supersaturated solid solution created by quenching is the necessary starting point for controlled precipitation during subsequent aging. Without it, the alloy cannot achieve its maximum strength.

Improve Ductility/Formability: For some alloys, solution treatment (followed by rapid quenching) leaves the material in a relatively soft and ductile state, making it easier to form, machine, or weld before a final strengthening treatment.

Improve Corrosion Resistance: In some stainless steels (e.g., 304, 316), solution treatment is used to dissolve harmful chromium carbides that might form at grain boundaries during welding or slow cooling, thus restoring full corrosion resistance.

Solution treatment is a testament to how precisely we can manipulate the atomic structure of metals through thermal cycles to engineer specific and enhanced material properties for various demanding applications.

Conclusion

Aluminum solution heat treatment furnaces are essential for precisely heating aluminum alloys to dissolve alloying elements, preparing them for strengthening. Solution heat treatment for 6061 involves heating to 520-540°C, holding for soak time, and rapid quenching to prepare for T6 temper. For aluminum sheets, heat treatment varies: heat-treatable alloys undergo solution heat treatment, quenching, and aging for strength, while non-heat-treatable alloys are typically annealed for softness. Generally, solution treatment in heat treatment is a high-temperature process that dissolves alloying elements into a solid solution, followed by rapid quenching to enable subsequent strengthening processes like precipitation hardening.