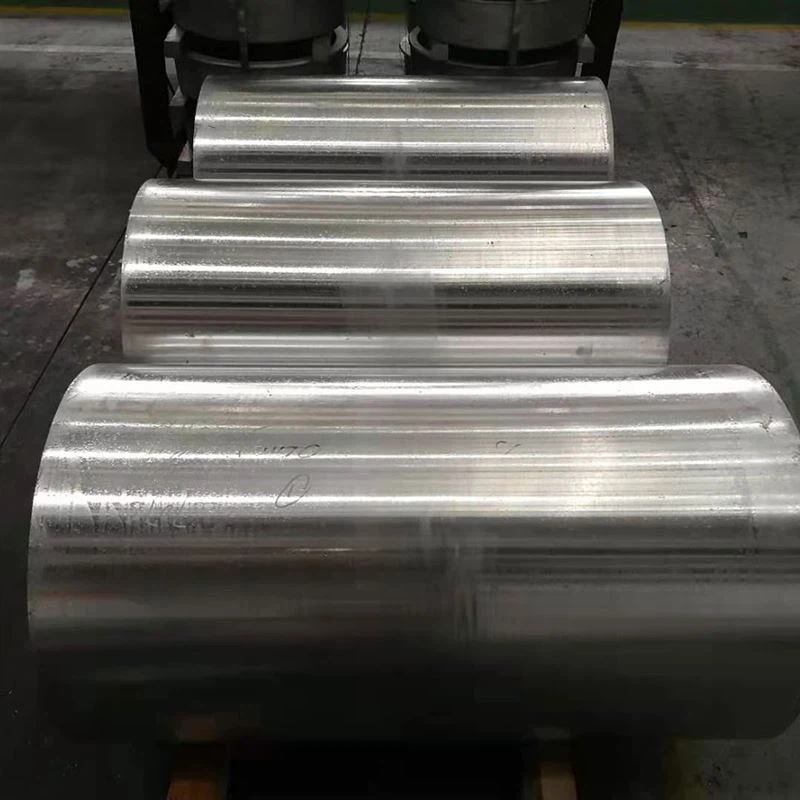

1. Material Composition & Manufacturing Process

7050 forged aluminum round bar is an ultra-high strength, heat-treatable aluminum-zinc-magnesium-copper alloy specifically engineered to provide exceptional strength, toughness, fatigue resistance, and superior stress corrosion cracking (SCC) resistance in critical structural components. Through precise forging, its internal microstructure is optimized, with grain flow aligned along the part’s contours, making it an ideal choice for aerospace, military, and extremely high-performance industrial applications:

Primary Alloying Elements:

Zinc (Zn): 5.9-6.9% (primary strengthening element)

Magnesium (Mg): 2.0-2.6% (works with zinc to form strengthening phases)

Copper (Cu): 2.0-2.6% (enhances strength and stress corrosion resistance)

Zirconium (Zr): 0.08-0.15% (grain refiner, inhibits recrystallization)

Base Material:

Aluminum (Al): Balance

Controlled Impurities:

Iron (Fe): ≤0.15% max

Silicon (Si): ≤0.12% max

Manganese (Mn): ≤0.10% max

Titanium (Ti): ≤0.06% max

Chromium (Cr): ≤0.04% max

Other elements: ≤0.05% each, ≤0.15% total

Premium Forging Process:

Melt Preparation:

High-purity primary aluminum (99.9% minimum)

Precise control of alloying elements with ±0.03% tolerance

Multi-stage filtration systems (ceramic foam filters, deep bed filters) for ultra-high cleanliness

Vacuum degassing or advanced SNIF degassing (hydrogen < 0.08 ml/100g)

Grain refinement and recrystallization control using Al-Zr master alloy

Advanced Direct-Chill (DC) casting technology for defect-free, large-sized ingots

Homogenization:

Multi-stage homogenization at 460-480°C for 24-48 hours

Strict temperature control: ±3°C

Slow cooling rates to ensure uniform distribution of alloying elements and eliminate macro-segregation

Billet Preparation:

Surface conditioning (scalping or milling)

100% ultrasonic inspection (conforming to AMS 2630 class A1 or ASTM E2375 Level 2)

Preheating: 380-420°C, with precise temperature uniformity control

Forging Sequence:

Multi-stage forging, including open-die, closed-die, or radial forging

Deformation temperature: 350-400°C (precisely controlled below recrystallization temperature)

Hydraulic press capacity: 5,000-50,000 tons (depending on bar size and complexity)

Computer-aided design and control to optimize grain flow and deformation rates

Minimum reduction ratio: 4:1 to 6:1, ensuring dense, uniform internal structure and elimination of cast structure

Solution Heat Treatment:

475-485°C for 2-4 hours (diameter dependent)

Temperature uniformity: ±3°C

Rapid transfer to quenching medium (<5 seconds)

Quenching:

Hot water quench (60-80°C) or polymer quench

Controlled cooling rate to optimize corrosion resistance

Stress Relief (for T7451/T74511 Tempers):

Controlled stretching (1-3% plastic deformation) to reduce residual stress

Two-Stage Artificial Aging (for T7451/T74511 Tempers):

First stage: 120°C for 6-10 hours (formation of GP zones)

Second stage: 160°C for 8-16 hours (formation of η’ and η phases, enhancing SCC resistance)

All production stages are subject to stringent quality control, non-destructive testing, and traceability management.

2. Mechanical Properties of 7050 Forged Round Bar

| Property | T7451 | T74511 | T7651 | T76511 | Test Method |

| Ultimate Tensile Strength | 500-550 MPa | 500-550 MPa | 520-570 MPa | 520-570 MPa | ASTM E8 |

| Yield Strength (0.2%) | 450-500 MPa | 450-500 MPa | 470-520 MPa | 470-520 MPa | ASTM E8 |

| Elongation (2 inch) | 8-12% | 8-12% | 7-10% | 7-10% | ASTM E8 |

| Hardness (Brinell) | 150-165 HB | 150-165 HB | 160-175 HB | 160-175 HB | ASTM E10 |

| Fatigue Strength (5×10⁷ Cycles) | 170-200 MPa | 170-200 MPa | 180-210 MPa | 180-210 MPa | ASTM E466 |

| Shear Strength | 280-320 MPa | 280-320 MPa | 300-340 MPa | 300-340 MPa | ASTM B769 |

| Fracture Toughness (K1C, typical) | 30-40 MPa√m | 30-40 MPa√m | 25-35 MPa√m | 25-35 MPa√m | ASTM E399 |

Property Distribution:

Axial vs. Radial properties: <5% variation in strength properties (forging provides excellent anisotropy)

Internal property variation across large diameter bars: typically less than 5%

Core to surface hardness variation: <5 HB

Toughness-strength balance: 7050 alloy offers superior fracture toughness compared to 7075-T6 while maintaining high strength

Stress Corrosion Cracking Resistance: T7451/T74511 tempers provide very high SCC resistance, superior to T6 tempers

3. Microstructural Characteristics

Key Microstructural Features:

Grain Structure:

Fine, uniform mixed structure of recrystallized and elongated grains

Grain flow aligned with the forging shape, oriented along the stress direction, providing excellent mechanical properties

Al₃Zr dispersoids formed by Zirconium effectively inhibit grain growth and recrystallization

ASTM grain size 6-9 (45-16μm)

Precipitate Distribution:

η’ (MgZn₂) and η (MgZn₂) phases: Formed via two-stage aging, providing primary strengthening

Cu and Mg content in solid solution is critical for SCC resistance

Extremely low quantity and controlled size of primary intermetallic compounds like Al₂CuMg, AlZnCu, Al₂Cu

Texture Development:

Controlled forging process creates specific texture, optimizing strength, toughness, and SCC resistance

Special Features:

Size and distribution of grain boundary precipitates (GP zones and η’) precisely controlled to maximize SCC resistance

Optimized zinc-depleted zones at grain boundaries, reducing anodic corrosion paths

High metallurgical cleanliness, minimizing inclusion defects

4. Dimensional Specifications & Tolerances

| Parameter | Standard Range | Precision Tolerance | Commercial Tolerance | Test Method |

| Diameter | 100-700 mm | ±0.4mm up to 200mm | ±0.8mm up to 200mm | Micrometer/Caliper |

| ±0.2% above 200mm | ±0.4% above 200mm | |||

| Ovality | N/A | 40% of diameter tolerance | 60% of diameter tolerance | Micrometer/Caliper |

| Length | 1000-6000 mm | ±3mm | ±6mm | Tape measure |

| Straightness | N/A | 0.4mm/m | 0.8mm/m | Straightedge/Laser |

| Surface Roughness | N/A | 1.6 μm Ra max | 3.2 μm Ra max | Profilometer |

| Cut End Squareness | N/A | 0.3° max | 0.6° max | Protractor |

Standard Available Forms:

Forged Round Bar: Diameters 100mm to 700mm

Custom cut-to-length service available

Special tolerances and surface finishes (e.g., peeled, ground, precision turned) available upon request

Available in various heat treatment tempers, such as T7451, T74511, T7651, T76511

5. Temper Designations & Heat Treatment Options

| Temper Code | Process Description | Optimal Applications | Key Characteristics |

| T7451 | Solution treated + stretched for stress relief + two-stage artificial aging | Excellent stress corrosion cracking resistance with high strength | High strength, superior SCC resistance, dimensional stability |

| T74511 | T7451 + straightened | Suitable for irregular sections, low residual stress | Similar to T7451, but for complex shapes |

| T7651 | Solution treated + stretched for stress relief + two-stage artificial aging | Excellent exfoliation corrosion resistance with high strength | High strength, superior exfoliation corrosion resistance |

| T76511 | T7651 + straightened | Suitable for irregular sections, low residual stress | Similar to T7651, but for complex shapes |

Temper Selection Guidance:

T7451/T74511: Primary choice when design requires a balance of high strength and exceptional stress corrosion cracking (SCC) resistance

T7651/T76511: Used when design requires slightly higher strength and specific resistance to exfoliation corrosion

Forging process provides more uniform properties in all directions and lower residual stress, making it more suitable for critical structural components

6. Machining & Fabrication Characteristics

| Operation | Tool Material | Recommended Parameters | Comments |

| Turning | Carbide, PCD | Vc=150-450 m/min, f=0.1-0.4 mm/rev | High-speed machining for excellent surface finish, attention to chip evacuation |

| Drilling | Carbide, TiN coated | Vc=60-150 m/min, f=0.1-0.3 mm/rev | Through-coolant drills recommended, good for deep holes |

| Milling | Carbide, HSS | Vc=200-700 m/min, fz=0.08-0.2 mm | High-positive rake angle tools, large depth of cut, high feed |

| Tapping | HSS-E-PM, TiCN coated | Vc=10-25 m/min | Proper lubrication for good thread quality |

| Reaming | Carbide, HSS | Vc=40-100 m/min, f=0.15-0.4 mm/rev | H7 tolerance achievable |

| Sawing | Carbide-tipped blade | Vc=600-1500 m/min | Suitable for precision cutting of large diameter bars |

Fabrication Guidance:

Machinability Rating: 50% (1100 aluminum = 100%), harder to machine than 6061, easier than 7075

Chip Formation: Tends to form fine, broken chips, but chips can pile up, requiring good chip evacuation

Coolant: Water-soluble cutting fluid (10-15% concentration), high flow rate cooling; oil-based cutting fluids can also be used

Tool Wear: Higher, recommend PCD or coated carbide tools

Weldability: Conventional welding methods are not recommended, limited to special applications (e.g., friction stir welding), significant strength loss after welding

Cold Working: Poor formability, not suitable for cold bending, stamping, etc.

Hot Working: Forging must be performed under strictly controlled temperature and strain rates

Surface Treatment: Can be anodized (sulfuric anodizing recommended), but may exhibit a yellowish tint due to higher copper content

Stress Corrosion Cracking: T7451/T74511 tempers offer very high SCC resistance, which is its primary advantage

7. Corrosion Resistance & Protection Systems

| Environment Type | Resistance Rating | Protection Method | Expected Performance |

| Industrial Atmosphere | Good | Anodizing + sealing | 10-15 years |

| Marine Atmosphere | Good | Anodizing + sealing/painting | 5-10 years |

| Seawater Immersion | Fair | Strict coating system, or cladding | Depends on coating quality and maintenance |

| High Humidity | Good | Anodizing + sealing | 10-15 years |

| Stress Corrosion | Excellent (T74/T76 tempers) | No additional protection needed | Extremely low susceptibility, superior to 7075-T6 |

| Exfoliation | Excellent (T76 temper) | No additional protection needed | Extremely low susceptibility |

| Galvanic Corrosion | Good | Proper isolation | Careful design with dissimilar metals |

Surface Protection Options:

Anodizing:

Type II (Sulfuric): 10-25μm thickness, enhances wear and corrosion resistance, can be dyed

Type III (Hard): 25-75μm thickness, for high wear applications

Conversion Coatings:

Chromate conversion coatings (MIL-DTL-5541): Excellent base for paints or adhesives, provides corrosion protection

Chromium-free alternatives: Environmentally compliant

Painting Systems:

Epoxy primer + polyurethane topcoat: Provides excellent long-term protection, suitable for aerospace environments

Cladding:

In extreme corrosive environments, cladding with pure aluminum or corrosion-resistant alloy layers may be considered

8. Physical Properties for Engineering Design

| Property | Value | Design Consideration |

| Density | 2.80 g/cm³ | Weight calculation and structural optimization |

| Melting Range | 482-635°C | Heat treatment window and welding limitations |

| Thermal Conductivity | 150 W/m·K | Thermal management, heat transfer design |

| Electrical Conductivity | 37-39% IACS | Electrical conductivity in electrical applications |

| Specific Heat | 860 J/kg·K | Thermal mass and heat capacity calculations |

| Thermal Expansion (CTE) | 23.6 ×10⁻⁶/K | Dimensional changes due to temperature variations |

| Young’s Modulus | 71.0 GPa | Deflection and stiffness calculations |

| Poisson’s Ratio | 0.33 | Structural analysis parameter |

| Damping Capacity | Medium-Low | Vibration and noise control |

Design Considerations:

Operating Temperature Range: -60°C to +100°C (strength significantly degrades above this)

Cryogenic Performance: Slight increase in strength at low temperatures, toughness remains good

Magnetic Properties: Non-magnetic

Recyclability: High-value recyclable material

Dimensional Stability: Excellent in T7451/T74511 tempers, suitable for precision machining

Strength-to-Weight Ratio: Among the highest for aluminum alloys, ideal for aerospace materials

9. Quality Assurance & Testing

Standard Testing Procedures:

Chemical Composition:

Optical emission spectroscopy

Inert gas fusion (hydrogen content)

Verification of all alloying elements and ultra-low impurity content

Mechanical Testing:

Tensile testing (longitudinal, transverse, short transverse)

Hardness testing (Brinell, multiple locations)

Fracture toughness testing (K1C, per ASTM E399)

Fatigue testing (as required, e.g., rotating beam fatigue)

Stress Corrosion Cracking testing (SCC, per ASTM G44, G47)

Nondestructive Testing:

Ultrasonic inspection (100% volumetric, per AMS 2630 class A1, AMS-STD-2154, or ASTM E2375 Level 2)

Eddy current testing (surface and near-surface defects)

Penetrant inspection (surface defects)

Radiographic testing (internal macroscopic defects)

Microstructural Analysis:

Grain size determination

Grain flow pattern verification

Precipitate evaluation (TEM/SEM)

Recrystallization degree assessment

Dimensional Inspection:

CMM (Coordinate Measuring Machine) verification

Diameter, length, straightness, ovality, etc.

Standard Certifications:

Mill Test Report (EN 10204 3.1 or 3.2)

Chemical analysis certification

Mechanical properties certification

Heat treatment/forging certification

Nondestructive testing certification

Conformance to AMS 4106 (forgings), AMS 4107 (bar), ASTM B247 (forgings), and other aerospace standards

AS9100 or ISO 9001 quality management system certification

10. Applications & Design Considerations

Primary Applications:

Aerospace Structures:

Fuselage frames, wing spars, stringers

Landing gear components

Aircraft connectors and fasteners

Engine pylon components

Military and Defense:

Military aircraft structural components

Missile and rocket structures

Critical load-bearing parts for armored vehicles

High-Performance Machinery:

High-precision test equipment components

Critical racing car parts

Molds and die components (in specific cases)

Design Advantages:

Ultra-high strength and excellent strength-to-weight ratio

Superior stress corrosion cracking (SCC) resistance (especially in T7451 temper)

Good fracture toughness, better than 7075-T6

Forging process optimizes grain flow, enhancing fatigue resistance and anisotropy

Lower quenching residual stress (through stress relief treatment)

Excellent dimensional stability, suitable for precision machining

Non-magnetic

Design Limitations:

High cost, primarily used for critical aerospace applications

Poor weldability, conventional welding not recommended

Extremely poor formability, not suitable for cold working

Poor heat resistance, performance degrades rapidly at elevated temperatures

Extremely demanding processing and heat treatment requirements, necessitating specialized equipment and strict control

Moderate corrosion resistance, typically requires anodizing or coating protection

Economic Considerations:

A high-performance alloy, initial cost is significantly higher than general-purpose aluminum alloys

Complex manufacturing and inspection processes add to production costs

Despite the high cost, its superior performance is irreplaceable in critical applications

Sustainability Aspects:

High-value recyclable material, contributing to circular economy

Lightweight design in aerospace contributes to reduced fuel consumption and carbon emissions

Production processes are under strict environmental regulation

Material Selection Guidance:

Choose 7050 when the design requires a balance of maximum strength, excellent fracture toughness, fatigue resistance, and superior stress corrosion cracking resistance, and cost is not the primary limiting factor

Particularly suitable for pressure-bearing components, landing gear, wing spars, and other critical aerospace structures

Choose T7651 temper when slightly higher strength is needed and specific resistance to exfoliation corrosion is required

Not suitable for applications requiring welding or complex cold forming