1. Material Composition & Manufacturing Process

6061 large diameter aluminum alloy bar is a versatile, heat-treatable aluminum-magnesium-silicon alloy that offers excellent strength, good corrosion resistance, superior weldability, and machinability across a wide range of diameters, making it ideal for structural, mechanical parts, transportation, and general engineering applications:

Primary Alloying Elements:

Magnesium (Mg): 0.8-1.2% (enhances strength)

Silicon (Si): 0.4-0.8% (forms Mg₂Si strengthening phase with Magnesium)

Copper (Cu): 0.15-0.40% (improves strength, slightly reduces corrosion resistance)

Chromium (Cr): 0.04-0.35% (inhibits recrystallization, improves stress corrosion resistance)

Base Material:

Aluminum (Al): ≥95.8% (balance)

Controlled Impurities:

Iron (Fe): ≤0.70% max

Zinc (Zn): ≤0.25% max

Manganese (Mn): ≤0.15% max

Titanium (Ti): ≤0.15% max

Other elements: ≤0.05% each, ≤0.15% total

Premium Manufacturing Process:

Melt Preparation:

High-purity primary aluminum (99.7% minimum)

Precise alloying element additions with ±0.05% tolerance

Advanced filtration through ceramic foam filters (30-40 ppi)

SNIF degassing treatment (hydrogen < 0.10 ml/100g)

Grain refinement with Al-Ti-B master alloy

Direct-chill (DC) semi-continuous casting to produce large diameter ingots

Homogenization:

550-580°C for 6-12 hours

Uniform temperature control: ±5°C

Controlled cooling rate: 15-25°C/hour

Dissolution of coarse intermetallics, elimination of microsegregation

Hot Working (Extrusion or Forging):

Large extrusion presses: Capable of producing bars up to 400mm diameter

Or Forging: Processing ingots into bars via radial forging or closed-die forging

Deformation temperature: 450-500°C

Ensures adequate deformation and grain refinement for optimal internal quality and grain flow

Solution Heat Treatment:

520-550°C for 1-4 hours (diameter dependent)

Temperature uniformity: ±3°C

Rapid transfer to quenching medium (<10 seconds)

Quenching:

Water quench or polymer quench

Controlled cooling rate for optimal hardness

Stress Relief (for T651/T6511 Tempers):

Controlled stretching (1-3% plastic deformation) to reduce residual stress

Artificial Aging (T6 Temper):

160-180°C for 8-18 hours

Temperature uniformity: ±3°C

All production stages are subject to rigorous quality control and traceability management.

2. Mechanical Properties of 6061 Large Diameter Aluminum Bar

| Property | O (Annealed) | T4 | T6 | T651/T6511 | Test Method |

| Ultimate Tensile Strength | 110-145 MPa | 180-220 MPa | 290-320 MPa | 290-320 MPa | ASTM E8 |

| Yield Strength (0.2%) | 40-60 MPa | 90-120 MPa | 240-270 MPa | 240-270 MPa | ASTM E8 |

| Elongation (2 inch) | 16-25% | 14-20% | 8-15% | 8-15% | ASTM E8 |

| Hardness (Brinell) | 30-40 HB | 60-75 HB | 95-105 HB | 95-105 HB | ASTM E10 |

| Fatigue Strength (5×10⁸ Cycles) | 70-90 MPa | 90-110 MPa | 95-110 MPa | 95-110 MPa | ASTM E466 |

| Shear Strength | 70-90 MPa | 110-130 MPa | 190-210 MPa | 190-210 MPa | ASTM B769 |

| Modulus of Elasticity | 68.9 GPa | 68.9 GPa | 68.9 GPa | 68.9 GPa | ASTM E111 |

Property Distribution:

Axial vs. Radial properties: <5% variation in strength properties

Internal property variation across large diameter bars: typically less than 7% for T6/T651 tempers

Core to surface hardness variation: <5 HB

Residual stress: Low stress levels in T651/T6511 tempers, reducing machining distortion

3. Microstructural Characteristics

Key Microstructural Features:

Grain Structure:

Elongated grains with some recrystallized grains after hot working

ASTM grain size 4-7 (90-32μm)

Ensures uniform grain structure and refinement within large diameter bars through strict process control

Precipitate Distribution:

Mg₂Si strengthening phase: Fine and uniformly dispersed, providing primary strengthening

AlFeSi intermetallics: Controlled size and distribution

Cr₂Si or Al₁₂Mg₂Cr dispersoids: Inhibits grain growth, improves stress corrosion resistance

Texture Development:

Fiber texture introduced by extrusion/forging

Texture strength has minor impact on mechanical properties; grain refinement and precipitation hardening are dominant

Special Features:

Uniform distribution of precipitates at grain boundaries

Supersaturated solid solution after solution treatment

Formation of precipitation phases after aging treatment

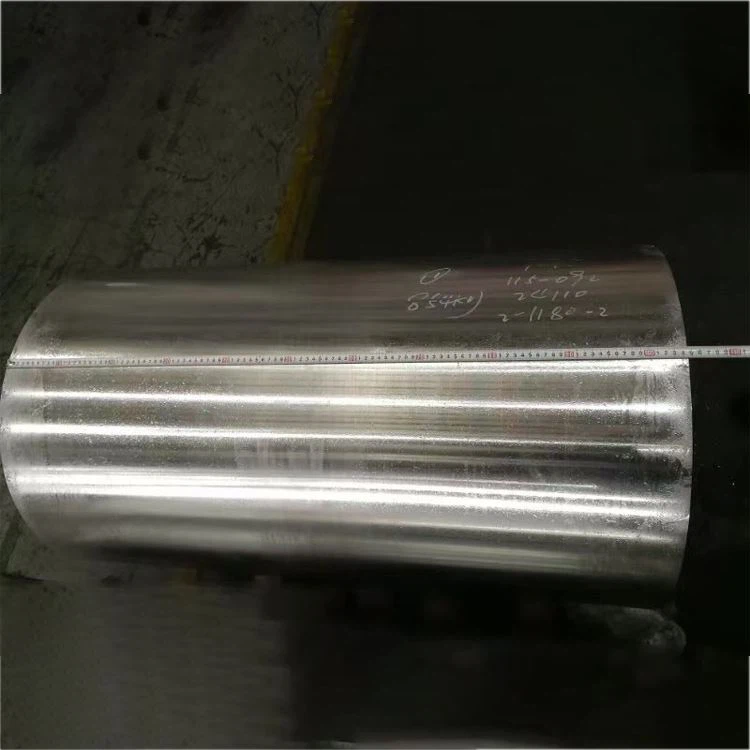

4. Dimensional Specifications & Tolerances

| Parameter | Standard Range | Precision Tolerance | Commercial Tolerance | Test Method |

| Diameter | 100-600 mm | ±0.5mm up to 200mm | ±1.0mm up to 200mm | Micrometer/Caliper |

| ±0.25% above 200mm | ±0.5% above 200mm | |||

| Ovality | N/A | 50% of diameter tolerance | 75% of diameter tolerance | Micrometer/Caliper |

| Length | 1000-7000 mm | ±5mm | ±10mm | Tape measure |

| Straightness | N/A | 0.8mm/m | 1.5mm/m | Straightedge/Laser |

| Surface Roughness | N/A | 3.2 μm Ra max | 6.3 μm Ra max | Profilometer |

| Cut End Squareness | N/A | 0.5° max | 1.0° max | Protractor |

Standard Available Forms:

Large Diameter Round Bar: Diameters 100mm to 600mm

Custom cut-to-length service available

Special tolerances and surface finishes (e.g., peeled, ground, precision turned) available upon request

Available in as-quenched and aged, or quenched-stretched-aged (T651) tempers

5. Temper Designations & Heat Treatment Options

| Temper Code | Process Description | Optimal Applications | Key Characteristics |

| O | Fully annealed, softened | Applications requiring maximum formability | Lowest strength, maximum ductility |

| T4 | Solution heat treated and naturally aged | Good formability with moderate strength requirements | Moderate strength, good formability |

| T6 | Solution heat treated and artificially aged | High-strength, structural applications | Maximum strength and hardness |

| T651 | T6 + stress relieved by stretching | Critical structural components, low residual stress | Excellent dimensional stability, low machining distortion |

| T6511 | T6 + slight stretch + straightening | Low residual stress for irregular shapes | Similar to T651, but for irregular cross-sections |

Temper Selection Guidance:

O: For complex cold forming operations

T4: For applications requiring subsequent forming or welding, with final heat treatment

T6: For general structural and mechanical parts requiring high strength

T651/T6511: For large diameter bars requiring minimal machining distortion and high dimensional stability

6. Machining & Fabrication Characteristics

| Operation | Tool Material | Recommended Parameters | Comments |

| Turning | Carbide, Diamond | Vc=250-600 m/min, f=0.1-0.5 mm/rev | High-speed machining yields excellent surface finish |

| Drilling | Carbide, TiN coated | Vc=80-200 m/min, f=0.15-0.40 mm/rev | Through-coolant drills recommended, good for deep holes |

| Milling | Carbide, HSS | Vc=200-800 m/min, fz=0.1-0.25 mm | High-positive rake angle tools, large depth of cut, high feed |

| Tapping | HSS-E-PM, TiCN coated | Vc=20-40 m/min | Good thread quality, easy to tap |

| Reaming | Carbide, HSS | Vc=80-150 m/min, f=0.2-0.6 mm/rev | H7/H8 tolerance achievable |

| Sawing | Carbide-tipped blade | Vc=1000-3000 m/min | Efficient cutting, smooth cut edges |

Fabrication Guidance:

Machinability Rating: 80% (1100 aluminum = 100%), improved machinability in T6 temper

Chip Formation: Easily forms short, curled chips, facilitating chip evacuation

Coolant: Water-soluble cutting fluid (5-10% concentration)

Tool Wear: Low, leading to long tool life

Weldability: Excellent with TIG and MIG welding, minimal strength loss after welding

Heat Treatment: Can be quenched and aged to enhance strength

Anodizing: Easily anodized for aesthetic and corrosion-resistant surfaces

Brazing and Soldering: Possible

Residual Stress: T651/T6511 tempers significantly reduce residual stress, minimizing machining distortion

7. Corrosion Resistance & Protection Systems

| Environment Type | Resistance Rating | Protection Method | Expected Performance |

| Industrial Atmosphere | Very Good | Clean surface, optional anodizing | 15-20+ years |

| Marine Atmosphere | Good | Anodizing + sealing or painting | 5-10+ years with maintenance |

| Seawater Immersion | Fair | Cathodic protection or painting | Dependent on coating quality |

| High Humidity | Very Good | Clean surface, optional anodizing | 10-15+ years |

| Stress Corrosion | Very Good | Excellent performance in T6 temper | Low susceptibility |

| Exfoliation | Very Good | Standard protection | Good resistance |

| Galvanic Corrosion | Good | Proper isolation | Careful design with dissimilar metals |

Surface Protection Options:

Anodizing:

Type II (Sulfuric): 10-25μm thickness, for decorative and general protection

Type III (Hard): 25-75μm thickness, for wear resistance and higher protection

Dyeing and sealing: Enhances aesthetics and corrosion resistance

Conversion Coatings:

Chromate conversion coatings (MIL-DTL-5541): Excellent adhesion and corrosion protection

Chromium-free alternatives: Environmentally compliant

Painting Systems:

Epoxy primer + polyurethane topcoat: For harsh environments

Powder coating: High durability and aesthetics

Others:

Electroplating, vacuum coating, etc.

8. Physical Properties for Engineering Design

| Property | Value | Design Consideration |

| Density | 2.70 g/cm³ | Weight calculation and structural optimization |

| Melting Range | 582-652°C | Heat treatment and welding window |

| Thermal Conductivity | 167 W/m·K | Heat dissipation and transfer design |

| Electrical Conductivity | 40-43% IACS | Electrical conductivity in electrical applications |

| Specific Heat | 897 J/kg·K | Thermal mass and heat capacity calculations |

| Thermal Expansion (CTE) | 23.6 ×10⁻⁶/K | Dimensional changes due to temperature variations |

| Young’s Modulus | 68.9 GPa | Deflection and stiffness calculations |

| Poisson’s Ratio | 0.33 | Structural analysis parameter |

| Damping Capacity | Medium-Low | Vibration and noise control |

Design Considerations:

Operating Temperature Range: -80°C to +150°C

High-Temperature Performance: Strength begins to decrease above 100°C

Cryogenic Performance: Slight increase in strength at low temperatures, no brittle transition

Magnetic Properties: Non-magnetic

Recyclability: 100% recyclable with high scrap value

Formability: Good in T4 temper, limited in T6 temper

Dimensional Stability: Excellent in T651/T6511 tempers, suitable for precision machining

Strength-to-Weight Ratio: Advantageous in structural applications

9. Quality Assurance & Testing

Standard Testing Procedures:

Chemical Composition:

Optical emission spectroscopy

X-ray fluorescence analysis

Verification of all major elements and impurity content

Mechanical Testing:

Tensile testing (longitudinal and transverse)

Hardness testing (Brinell, multiple locations)

Fatigue testing (as required)

Nondestructive Testing:

Ultrasonic inspection (100% volumetric, per ASTM B594/E2375)

Eddy current testing (surface and near-surface defects)

Penetrant inspection (surface defects)

Microstructural Analysis:

Grain size determination

Precipitate and intermetallic evaluation

Grain flow pattern verification (for forged bars)

Dimensional Inspection:

CMM (Coordinate Measuring Machine) verification

Diameter, length, straightness, ovality, etc.

Standard Certifications:

Material Test Report (EN 10204 3.1 or 3.2)

Chemical analysis certification

Mechanical properties certification

Heat treatment certification

Nondestructive testing certification

Conformance to ASTM B221 (for extruded bar), ASTM B211 (for rolled/cold-finished bar), or ASTM B247 (for forged bar) as applicable

10. Applications & Design Considerations

Primary Applications:

Structural Components:

Architectural frames and supports

Bridge components

Truck and marine structures

Automation machinery bases

Mechanical Parts:

Valve bodies, pump bodies

Drive shafts, gears

Bolts, nuts, fasteners

Jigs and fixtures

Transportation Industry:

Automotive parts (chassis, suspension)

Railway car components

Bicycle frames

Yacht and boat components

Electronics and Precision Equipment:

Semiconductor equipment parts

Electronic component housings

Medical device components

Optical equipment brackets

Recreation and Consumer Goods:

Fishing reels

Sporting goods

Photographic equipment

Design Advantages:

Good overall performance: high strength, corrosion resistance, easy to machine, weldable

Good strength-to-weight ratio in T6 temper

Significant strength improvement after quenching and aging

Low machining distortion in T651/T6511 tempers

Easy to anodize and apply various surface treatments

Excellent welding characteristics

Highly versatile for various industries

Non-magnetic for specific applications

Good recyclability

Design Limitations:

Lower strength compared to 7xxx series alloys

Corrosion resistance in some marine environments is not as good as 5xxx series alloys

Not suitable for applications requiring ultra-high hardness and wear resistance

Limited high-temperature strength performance (above 150°C)

Cold forming ability is not as good as alloys like 5052

Strength in the welded area may slightly decrease

Economic Considerations:

Excellent performance at a reasonable cost, making it ideal for many applications

Wide supply chain and production capacity

Relatively low machining costs

Good recyclability reduces scrap costs

Sustainability Aspects:

100% recyclable, high resource utilization

Lower energy consumption in production compared to steel

Relatively low environmental impact throughout its lifecycle

Long service life reduces replacement frequency

Complies with RoHS and REACH standards, free of harmful substances

Material Selection Guidance:

Choose 6061 when a general-purpose alloy with high strength, good weldability, and corrosion resistance is needed

Choose 5052 when maximum formability is required and strength is less critical

Consider 2xxx or 7xxx series alloys when higher strength is paramount and weldability is not a primary concern

T6 temper is suitable for most structural and mechanical parts

T651/T6511 tempers are suitable for parts requiring precision machining and low residual stress