1. Material Composition & Manufacturing Process

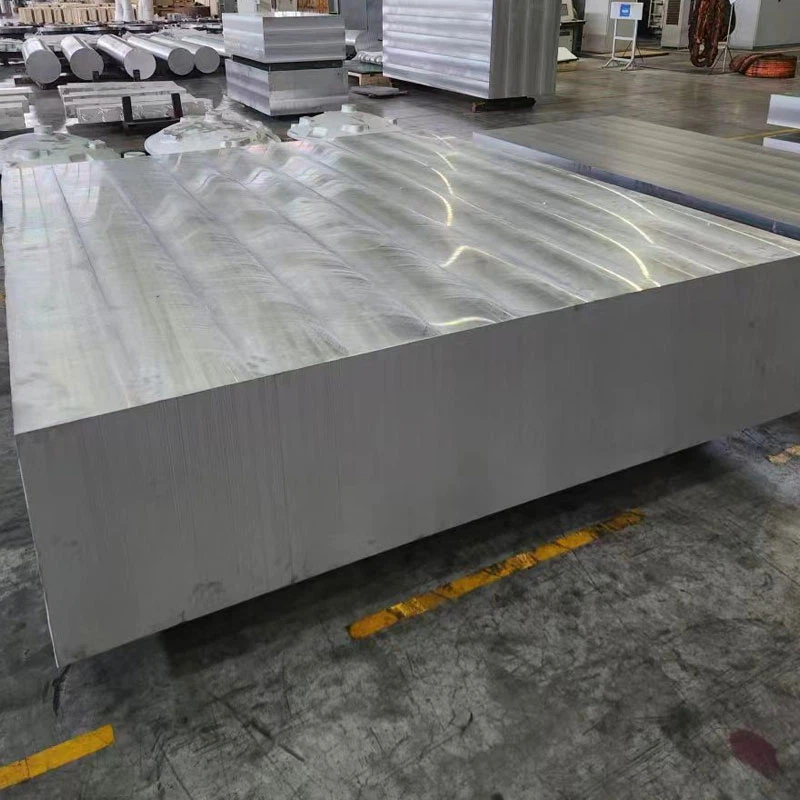

5083 aluminum alloy (ASTM B209, EN AW-5083) is a high-strength, non-heat-treatable Al-Mg alloy renowned for exceptional weldability and superior corrosion resistance in marine environments. The ultra-thick forged plate variant offers enhanced mechanical properties through controlled deformation processing:

Primary Alloying Elements:

Magnesium (Mg): 4.0-4.9% (primary solid-solution strengthener)

Manganese (Mn): 0.40-1.0% (grain structure refinement)

Chromium (Cr): 0.05-0.25% (corrosion resistance enhancement)

Titanium (Ti): 0.05-0.15% (grain refinement)

Base Material:

Aluminum (Al): ≥92.4% (balance)

Controlled Impurities:

Iron (Fe): ≤0.40% max

Silicon (Si): ≤0.40% max

Copper (Cu): ≤0.10% max

Zinc (Zn): ≤0.25% max

Specialized Ultra-Thick Forging Process:

Premium Ingot Production:

Direct Chill (DC) semi-continuous casting

Grain refinement with Ti-B additions

Melt degassing to <0.1ml H₂/100g Al

Filtration through ceramic foam filters

Homogenization Treatment:

500-520°C for 24-36 hours

Computer-controlled cooling rate

Microstructural equilibration

Surface Preparation:

Scalping of segregation layer (minimum 10mm)

Surface inspection for defects

Preheating for Forging:

Staged heating to 380-430°C

Temperature uniformity ±5°C

Multi-Directional Open-Die Forging:

Initial forging temperature: 400-425°C

Final forging temperature: 340-380°C

Deformation ratio: 3:1 to 5:1

Multi-directional working to optimize properties

Specialized dies for ultra-thick sections

Controlled Cooling:

Programmed cooling rate to minimize residual stress

Air-cooling with thermal blankets for thick sections

Stress Relief Treatment:

240-300°C for 1 hour per 25mm thickness

Furnace cooling to below 200°C

Final Processing:

Precision machining to customer specifications

Surface inspection and cleaning

Protective packaging for shipment

All manufacturing processes are performed under ISO 9001 quality management system with complete traceability.

2. Mechanical Properties of Ultra-Thick 5083 Forged Plate

| Property | Minimum | Typical | Test Standard | Ultra-Thick Advantage |

| Ultimate Tensile Strength | 290 MPa | 305-330 MPa | ASTM B557 | Uniform properties throughout section |

| Yield Strength (0.2%) | 145 MPa | 160-185 MPa | ASTM B557 | Enhanced through-thickness strength |

| Elongation (50mm gauge) | 12% | 16-22% | ASTM B557 | Superior ductility across full section |

| Hardness (Brinell) | 85 HB | 90-100 HB | ASTM E10 | Consistent hardness profile |

| Shear Strength | 175 MPa | 185-200 MPa | ASTM B769 | Enhanced joint reliability |

| Fatigue Strength (10⁸) | 120 MPa | 125-140 MPa | ASTM E466 | Improved cyclic loading performance |

| Compressive Yield | 145 MPa | 160-190 MPa | ASTM E9 | Critical for load-bearing applications |

| Bearing Strength (e/D=2.0) | 385 MPa | 400-430 MPa | ASTM E238 | Superior fastener performance |

| Impact Energy (Charpy) | 35 J | 40-50 J | ASTM E23 | Enhanced toughness at low temperatures |

Through-Thickness Performance:

Property variation <5% between surface and core (up to 200mm thickness)

Directionality ratio (L:LT:ST): 1.00:0.95:0.90 for tensile strength

Core temperature maintained within critical processing window

Hardness variation <8 HB from surface to center

3. Microstructural Control for Ultra-Thick Sections

Critical Forging Parameters:

Strain Distribution Control:

Minimum total true strain: 1.1-1.3

Strain rate: 0.01-0.1 s⁻¹

Multi-directional working (minimum 25% in secondary direction)

Intermittent reheating for sections >150mm

Temperature Management:

Maximum temperature gradient: 30°C across section

Computer-controlled thermal profile monitoring

Extended dwell times for temperature homogenization

Specialized handling equipment for minimal heat loss

Microstructural Characteristics:

Grain Size: ASTM 5-7 (30-60μm)

Grain Morphology: Partially recrystallized structure

Al₆Mn dispersoid distribution: 0.1-0.5μm diameter

Mg₂Si precipitate control: <0.5 volume percent

Al-Fe-Mn intermetallic phases: Controlled morphology

Recrystallized Volume Fraction: 40-60%

Texture: Mixed deformation/recrystallization texture

Grain Aspect Ratio: 1.5:1 maximum in final product

Special Features:

Subgrain structure with high misorientation angles

Limited recovery due to Mg solute drag effect

Al₃Mg₂ precipitation controlled to prevent sensitization

Enhanced dislocation density: 5-8×10¹⁰/cm²

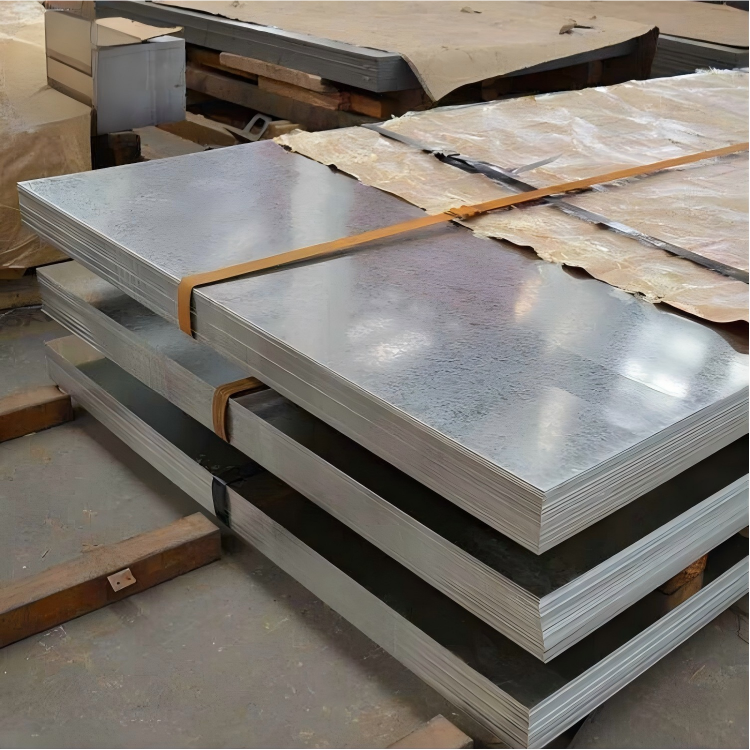

4. Dimensional Specifications & Tolerances

| Parameter | Standard Range | Precision Tolerance | Commercial Tolerance |

| Thickness | 150-400 mm | ±3 mm | ±5 mm |

| Width | 1000-3000 mm | ±5 mm | ±8 mm |

| Length | 2000-8000 mm | ±7 mm | ±12 mm |

| Flatness | N/A | 0.2% of length | 0.4% of length |

| Parallelism | N/A | 0.6% of thickness | 1.0% of thickness |

| Edge Straightness | N/A | 2 mm/m | 4 mm/m |

| Surface Roughness | N/A | 6.4 μm Ra max | 12.5 μm Ra max |

Ultra-Thick Specific Parameters:

Density: 2.66 g/cm³ (±0.01)

Weight Calculation: Thickness(mm) × Width(m) × Length(m) × 2.66 = Weight(kg)

Maximum Single Plate Weight: 20,000 kg

Machining Allowance: Recommend 15mm per side minimum for critical dimensions

Stress Relief: Required before precision machining for plates >200mm

Plate Flatness: Measured under self-weight on flat surface

Ultrasonic Testing: 100% volumetric inspection available

5. Corrosion Resistance Performance

| Environment | Performance | Corrosion Rate | Expected Service Life |

| Marine Atmosphere | Excellent | <0.02 mm/year | 30+ years |

| Immersed Seawater | Very Good | <0.10 mm/year | 25+ years |

| Industrial Exposure | Excellent | <0.05 mm/year | 25+ years |

| Fresh Water | Excellent | Negligible | 40+ years |

| Stress Corrosion | Excellent | Highly resistant | Design life |

| Exfoliation | Excellent | EXCO rating EA | Design life |

| Galvanic Coupling | Fair | Isolation required | Application dependent |

Corrosion Protection Options:

Anodizing:

Type II (Sulfuric acid): 10-25μm thickness

Type III (Hard anodize): 25-75μm thickness

Marine-grade sealing treatments

Conversion Coatings:

Chromate conversion per MIL-DTL-5541

Chrome-free alternatives for environmental compliance

Titanium/Zirconium-based treatments

Protective Systems:

Epoxy primer + polyurethane topcoat

Marine-grade multi-layer systems

Sacrificial zinc-rich primers

High-build epoxy coatings for immersion service

Environmental Performance Factors:

Sensitization Resistance: Superior to 5086 alloy

NAMLT Test Performance: <15mg/cm²

IGC Resistance: Excellent after stabilization treatment

H₂ Embrittlement: Minimal susceptibility

6. Machining & Fabrication Characteristics

| Operation | Tool Material | Recommended Parameters | Notes for Ultra-Thick Sections |

| Heavy Milling | Carbide | Vc=300-600 m/min, fz=0.15-0.30 mm | Climb milling recommended |

| Deep Hole Drilling | Carbide drills | Vc=60-100 m/min, fn=0.15-0.25 mm/rev | Step drilling for deep holes |

| Face Milling | PCD cutters | Vc=500-1000 m/min | High positive rake angles |

| Turning | Carbide/PCD | Vc=200-500 m/min | Rigid setup essential |

| Tapping | HSS-E taps | Vc=10-20 m/min | 50% thread recommended |

| Sawing | Carbide-tipped | 40-60 m/min | Flood coolant mandatory |

Fabrication Considerations:

Forming Limits: Minimum bend radius 2.5× material thickness

Cold Working: Limited to 15-20% before annealing

Hot Working: 260-370°C optimal temperature range

Weldability: Excellent with 5183, 5356, or 5556 filler

Welding Methods: GMAW, GTAW, FCAW suitable

Post-weld Treatment: Brush/needle scaling recommended

Stress Relief After Welding: 200°C for 1 hour per 25mm

Cutting Methods: Plasma, waterjet, or sawing preferred

7. Welding Performance & Recommendations

| Welding Process | Filler Material | Parameters | Special Considerations |

| GMAW (MIG) | ER5183, ER5556 | DCEP, 22-26V, 140-250A | Pulse spray transfer recommended |

| GTAW (TIG) | ER5183, ER5356 | AC, 12-15V, 120-200A | Thoriated tungsten electrodes |

| FCAW | E5183T, E5556T | DCEP, 24-28V, 150-260A | Minimal interpass cleaning |

| SAW | ER5183, ER5356 | 26-30V, 350-550A | Neutral or slightly basic flux |

Welding Best Practices for Ultra-Thick Sections:

Joint Preparation:

X-groove or double-V for thickness >25mm

Root gap 2-4mm

Root face 1-3mm

Bevel angle 50-60°

Thorough degreasing with acetone or MEK

Preheating:

Generally not required

For sections >200mm, preheat 50-80°C to reduce thermal gradient

Interpass Temperature:

Maximum 120°C

Monitor with infrared thermometer

Post-weld Treatment:

Stress relief recommended for thick sections

Thorough cleaning of flux and spatter

Inspection Methods:

Visual inspection per AWS D1.2

Radiographic or ultrasonic testing for critical joints

Dye penetrant for surface defects

8. Physical Properties for Engineering Design

| Property | Value | Design Implications |

| Density | 2.66 g/cm³ | Weight calculations and buoyancy |

| Melting Range | 574-638°C | Welding and heat treatment parameters |

| Thermal Conductivity | 117 W/m·K | Heat dissipation in thermal applications |

| Electrical Conductivity | 29% IACS | Electrical applications and design |

| Specific Heat Capacity | 900 J/kg·K | Thermal inertia calculations |

| Thermal Expansion | 23.8 ×10⁻⁶/K | Expansion joint design and thermal stress |

| Young’s Modulus | 71 GPa | Structural stiffness and deflection |

| Poisson’s Ratio | 0.33 | Strain relationships in complex loading |

| Damping Capacity | Moderate (0.01-0.02) | Vibration control applications |

Environmental Performance:

Operating Temperature Range: -196°C to +200°C

Cryogenic Performance: Excellent toughness retention

Fire Resistance: Non-combustible

Magnetic Properties: Non-magnetic

Radiation Resistance: Excellent

Recyclability: 100% recyclable with no quality loss

Environmental Impact: Lower energy footprint than steel

9. Quality Assurance & Testing Protocol

Standard Inspection Regime:

Chemical Composition Testing:

Optical emission spectroscopy

Verification of all alloying elements

Mechanical Testing:

Tensile testing (longitudinal and transverse directions)

Hardness mapping (surface and cross-section)

Impact testing for critical applications

Non-Destructive Testing:

Ultrasonic inspection per ASTM A578/A578M

Dye penetrant inspection for surface defects

Dimensional Inspection:

CMM verification of critical dimensions

Thickness mapping at specified grid points

Flatness measurement under self-weight

Microstructural Analysis:

Grain size determination

Inclusion rating per ASTM E45

Sensitization testing for H tempers

Metallographic examination

Certification Options:

Mill Test Report (EN 10204 3.1)

Third-party inspection certification (EN 10204 3.2)

DNV-GL certification for marine applications

ABS certification for marine structures

Lloyd’s Register certification

Customer-specific certification requirements

Material traceability documentation

Production record documentation

10. Industrial Applications & Use Cases

Primary Applications:

Naval and commercial shipbuilding

Offshore oil & gas platforms

Pressure vessel components

Cryogenic storage and transport

Heavy transportation structures

Bridge decking and structural components

Defense industry applications

Chemical processing equipment

Mining equipment structures

Marine propulsion system components

Specific Use Cases:

LNG Carrier Structural Components:

Superior low-temperature toughness

Excellent weldability for complex structures

Good strength-to-weight ratio