1. Material Composition & Standards

• Conforms to ASTM B209, GB/T 3190, EN 485-2

• Key elements: Zn (5.6%), Mg (2.5%), Cu (1.6%), Al (~87.1%)

2. Strength Properties

• Tensile Strength: ≥572 MPa (T6 temper)

• Yield Strength: ≥503 MPa

• Hardness: ~150 HB (Brinell)

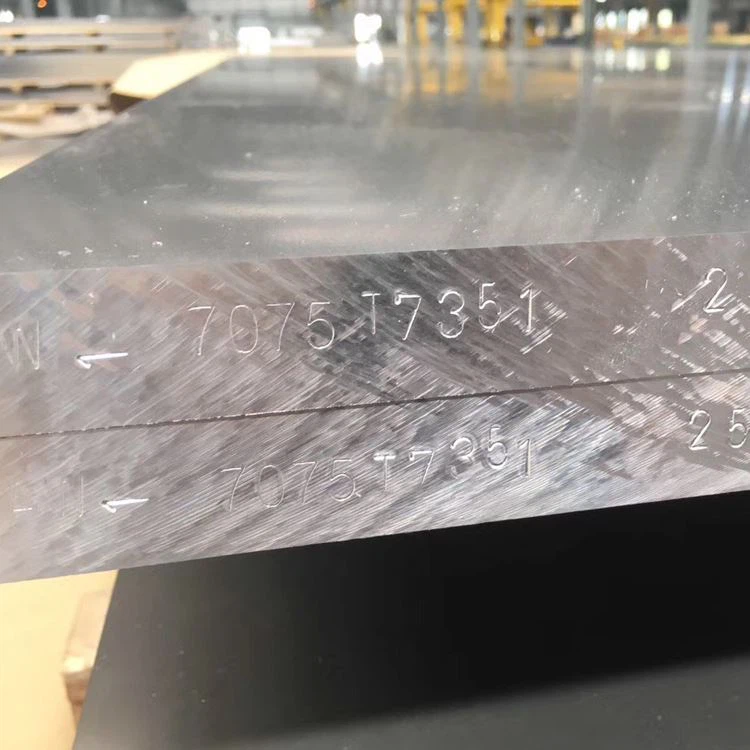

3. Heat Treatment Tempers

Common tempers: O, T6, T651, T73, T7351

Optimal choice: T651 (excellent machinability + low distortion)

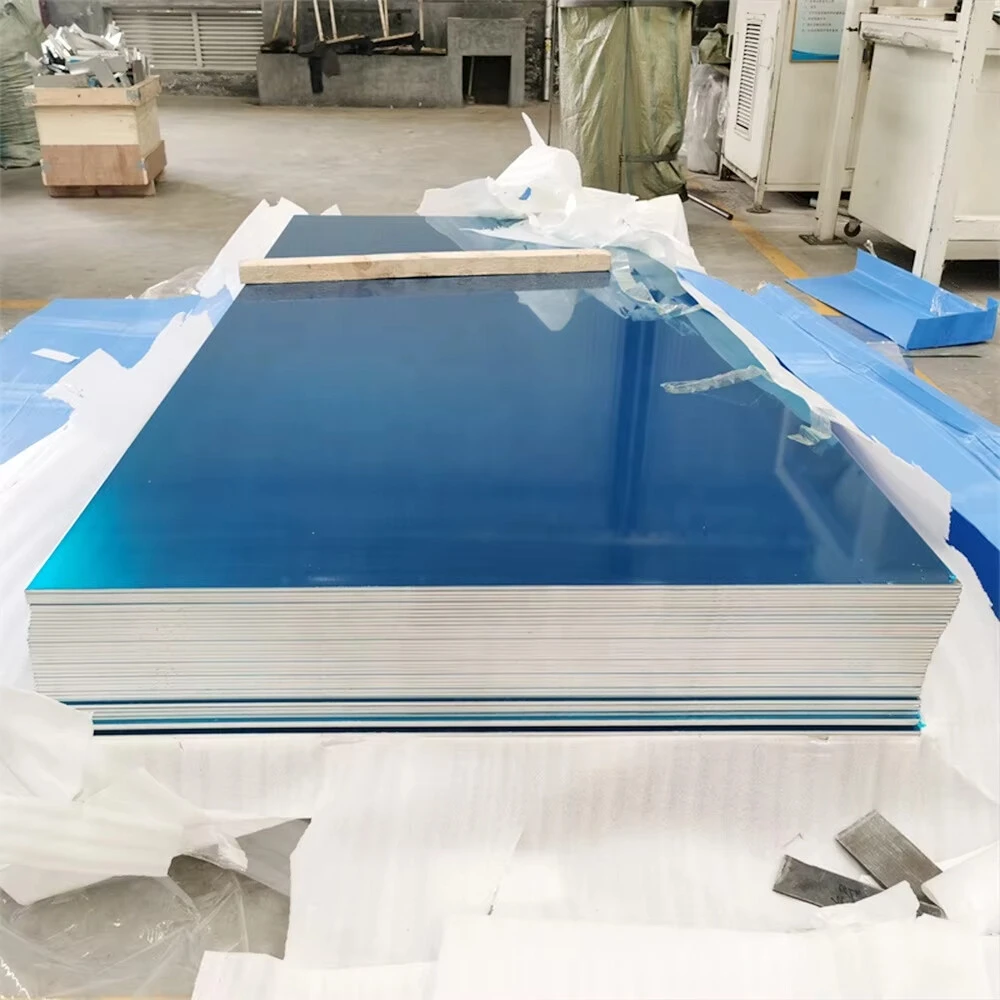

4. Dimensions & Customization

• Thickness range: 6–300 mm

• Services: Full plates, cut-to-size, blocks

5. Corrosion Resistance & Surface Treatment

• Lower corrosion resistance than 5xxx/6xxx series

• Solutions: Anodizing, protective coatings, anti-oxidation film

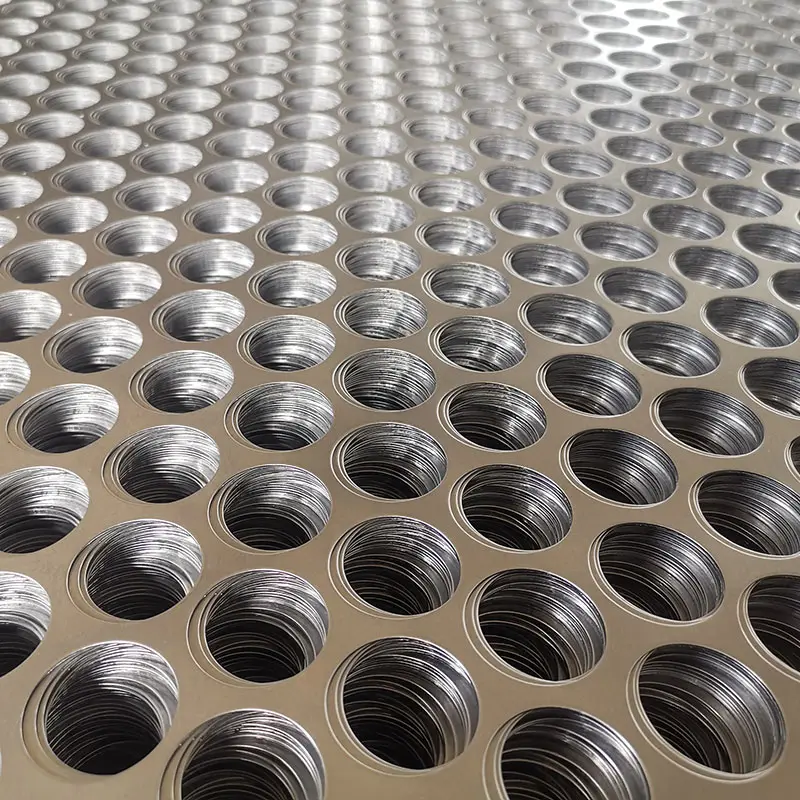

6. Machinability

• CNC machining/cutting/drilling/milling supported

• Semi-finished parts available

7. Weldability & Formability

• Poor weldability – Recommend mechanical joining

• Alternatives provided for crack-sensitive applications

8. Density & Weight

• Density: 2.81 g/cm³

• Ideal for aerospace/racing lightweight structures

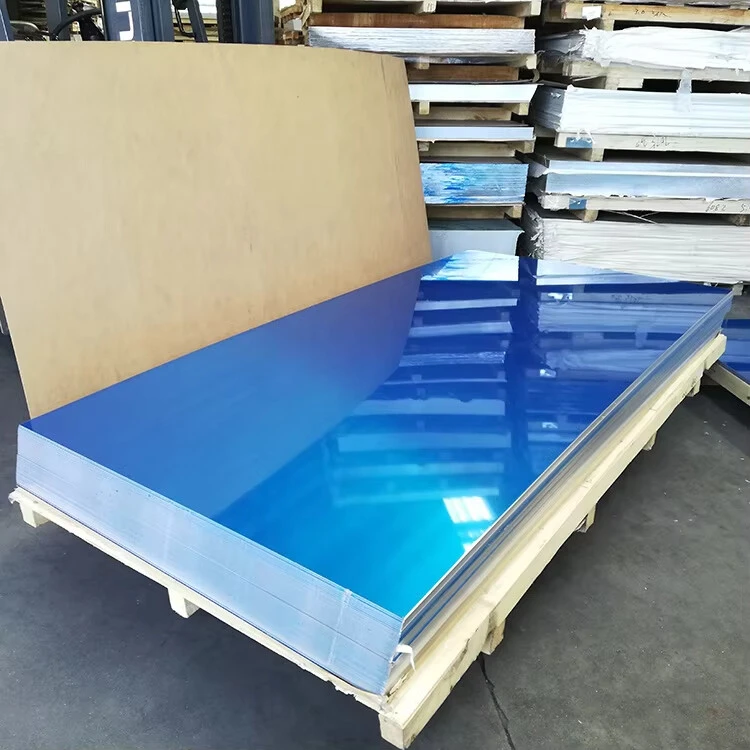

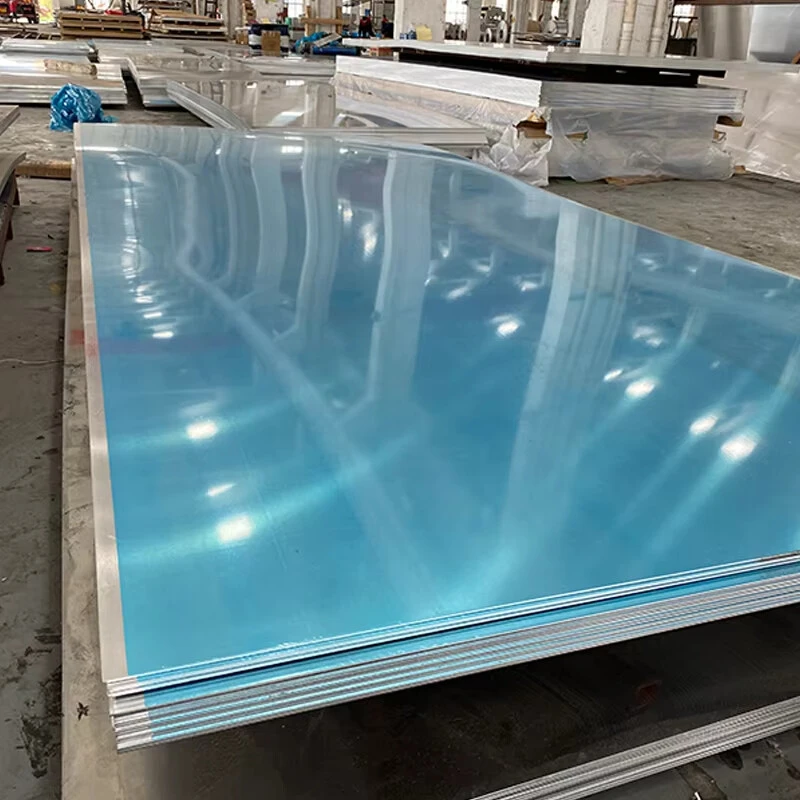

9. Surface Quality

• Strict control on waviness, oxidation marks, burrs

• Surface roughness: Customizable for mirror finishes

10. Certifications

• MTC (Material Test Certificates)

• Third-party reports: SGS, TÜV, ISO 9001

11. Applications

• Aerospace components • Mold manufacturing • Bicycle parts • High-stress structures

12. MOQ Policy

• Low MOQ accepted • Samples available

13. Fatigue Resistance

• Exceptional fatigue resistance under cyclic loading (Critical for aviation)

14. Thermal Expansion Coefficient

• 21.2 µm/m·°C (20–100°C)

• Ensures dimensional stability in high-precision assemblies

15. Conductivity

• Electrical: 33% IACS

• Thermal: 130 W/m·K

16. Internal Integrity

• Ultrasonic Testing (UT) for voids/inclusions detection

• Essential for aerospace/military grades

17. Flatness Control

• Stretch-leveling applied

• Tolerance: ±0.3mm/m or tighter

18. Sustainability

• REACH/RoHS compliant • Recyclable • Eco-friendly production

19. Delivery & Stock

• Regular specs in stock • Stable lead times for bulk orders

20. Packaging & Shipping

• VCI paper + moisture-proof wrapping + wooden crates

• Anti-deformation supports for marine transport

21. Competitive Alloy Comparison

| Parameter | 7075 | 6061 | 2024 |

|---|---|---|---|

| Strength | ★★★★★ | ★★★☆☆ | ★★★★☆ |

| Corrosion Res. | ★★☆☆☆ | ★★★★★ | ★★★☆☆ |

22. Manufacturer Credentials

• SWA Forging (ISO 9001/14001/45001 certified)

• Export licenses • Mill certificates

23. Custom Services

• Tailored: OD/ID tolerance, surface brushing, anodizing

• OEM/ODM projects welcomed