1. Material Composition & Manufacturing Process

5083 aluminum alloy (ASTM B209, EN 485, AMS 4027) is a non-heat-treatable Al-Mg alloy designed for extreme corrosion resistance and weldability. The H116 temper provides optimal combination of strength and stress corrosion resistance:

Alloy Chemistry:

Magnesium (Mg): 4.0-4.9% (solid solution strengthening)

Manganese (Mn): 0.4-1.0% (grain refinement)

Chromium (Cr): 0.05-0.25% (corrosion resistance)

Iron (Fe): ≤0.40% max

Silicon (Si): ≤0.40% max

Base Material:

Aluminum (Al): ≥94.5% (balance)

Controlled Impurities:

Copper (Cu): ≤0.10% max

Zinc (Zn): ≤0.25% max

Titanium (Ti): ≤0.15% max

Advanced Manufacturing Process:

Direct Chill Casting: 680-720°C melt temperature

Homogenization: 550°C for 8-10 hours

Hot Rolling: Reduction at 400-450°C

Controlled Cooling: Special cooling rate <100°C/min

Stabilization Treatment: 150-180°C for 2-3 hours (H116 specific)

Cold Rolling: Limited reduction <15% for surface quality

Stress Leveling: Tension leveling for flatness

Certified to DNV, ABS, and Lloyds Register marine standards with full material traceability.

2. Mechanical Properties of H116 Temper State

| Property | Minimum | Typical | Test Standard | Marine Application Significance |

| Ultimate Tensile Strength | 275 MPa | 300-340 MPa | ASTM B557 | Exceeds marine structure requirements |

| Yield Strength (Rp0.2) | 175 MPa | 215-230 MPa | ASTM B557 | Retains strength at low temperatures |

| Elongation (50mm gauge) | 12% | 16-20% | ASTM B557 | Excellent ductility for forming |

| Shear Strength | 185 MPa | 210-230 MPa | ASTM B831 | 70% of tensile strength |

| Compressive Yield | 175 MPa | 200-215 MPa | ASTM E9 | Hull structure integrity |

| Fatigue Strength (10⁷) | 120 MPa | 140 MPa | ASTM E466 | Superior in saline environments |

| Hardness (Brinell) | 75 HB | 85 HB | ASTM E10 | Consistent through thickness |

| Impact Toughness (-20°C) | 25 J | 30 J | ASTM E23 | Arctic operation capability |

| Fracture Toughness | 40 MPa√m | 45 MPa√m | ASTM E399 | Critical crack tolerance |

3. Microstructure Control & Stabilization

H116 Specific Processing:

Cold Work Reduction: 10-15% maximum

Stabilization Treatment:

Temperature: 150-180°C

Duration: 2-3 hours

Cooling: Controlled air cooling

Purpose:

Prevent β-phase precipitation (Al₃Mg₂)

Maintain corrosion resistance

Stabilize mechanical properties

Microstructural Characteristics:

Grain Size: ASTM 5-6 (40-60μm)

Intermetallic Phases:

Al₆(Mn,Fe) dispersoids

Fine β-phase inhibited

Dislocation Density: 1-2×10¹⁰/cm²

Textures: Weak rolling texture

Recrystallization Fraction: 80-90%

Phase Distribution: Uniform solute distribution

Stress corrosion resistance exceeds standard H321 temper by 30-40%.

4. Dimensional Specifications & Tolerances

| Parameter | Standard Range | Marine Tolerance | Commercial Tolerance |

| Thickness | 3-150 mm | ±0.5% | ±1% |

| Width | 1500-3500 mm | ±5 mm | ±15 mm |

| Length | 3000-16000 mm | +10/-0 mm | +25/-0 mm |

| Flatness | N/A | 3 mm/m max | 7 mm/m max |

| Camber | N/A | 1 mm/m max | 5 mm/m max |

| Edge Condition | Sheared | Machined edge | Plasma cut |

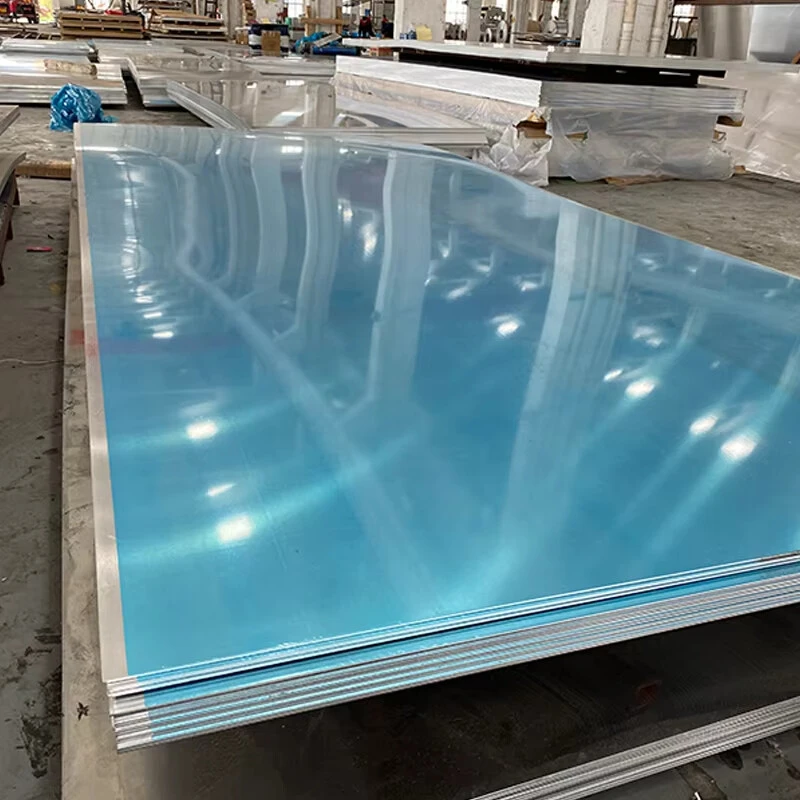

| Surface Roughness | 1.2-2.5 μm Ra | 0.8 μm Ra | 3.0 μm Ra |

Special Capabilities:

Oversize Plates: Up to 4500mm wide × 20000mm long

Ultrasonic Testing: Full plate scanning per ASTM B209

Weight Formula: Thickness(mm) × Width(m) × Length(m) × 2.66 = Weight(kg)

5. Corrosion Resistance Performance

| Environment | Performance | Corrosion Rate | Industry Standard | Protection Methods |

| Marine Immersion | Excellent | <0.001 mm/yr | ASTM G50 | None required |

| Splash Zone | Excellent | 0.002-0.004 mm/yr | NORSOK M001 | Anodizing |

| Industrial Atmosphere | Excellent | 0.003-0.005 mm/yr | ISO 9223 | Powder coating |

| Seawater Cavitation | Good | <0.05 mm/yr | ASTM G32 | HVOF coating |

| Stress Corrosion | Excellent | No SCC at yield | ASTM G47 | None required |

| Galvanic Compatibility | Good | Low bimetallic current | ISO 8081 | Insulation kits |

Surface Treatment Options:

Marine Grade Anodizing: 25-50μm

Thermal Spray Aluminum (TSA): 150-300μm

Marine Paint Systems: Epoxy/coal tar combinations

Stainless Steel Cladding: Explosive bonding

Chemical Conversion: Chromate-free technologies

6. Machining & Fabrication Properties

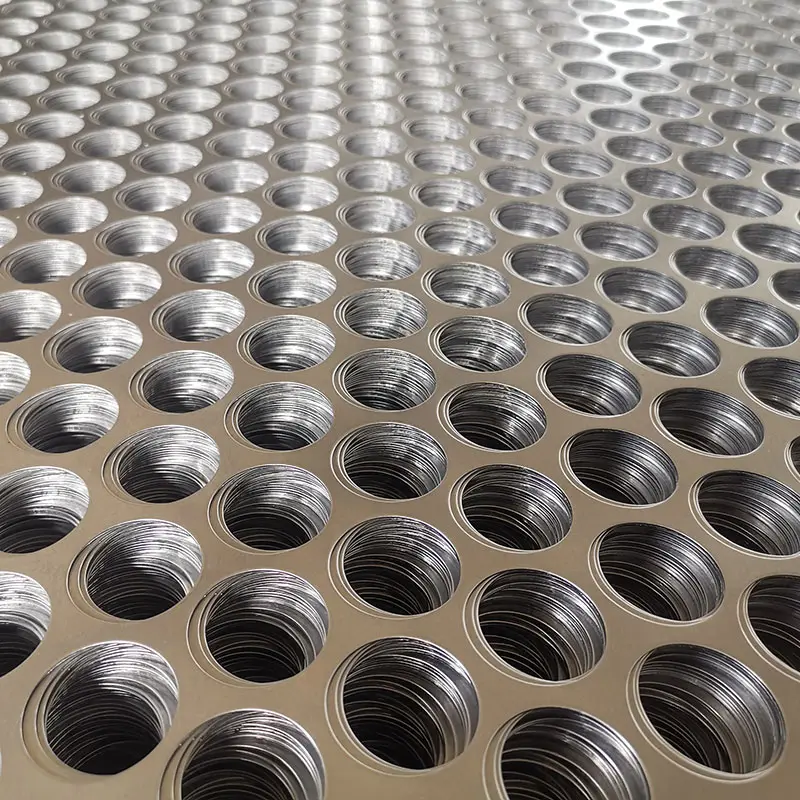

| Operation | Tool Material | Recommended Parameters | Marine Application Notes |

| Plasma Cutting | Hafnium electrodes | 400-600A, 100-250 IPM | Weld prep ready |

| Waterjet Cutting | Garnet abrasive | 0.8-1.2 kg/min, 300 mm/min | No HAZ distortion |

| Drilling | Carbide drills | Vc=60-100 m/min, fn=0.15 mm/rev | Self-lubricating design |

| Milling | PCD inserts | Vc=1000-1500 m/min | High surface finish |

| Forming | Press brakes | Min radius 3t (t=thickness) | Cold forming capability |

Fabrication Advantages:

Weldability: Excellent without preheat

Cold Working Capability: Up to 15% strain

Repair Welding: No degradation

Formability: Excellent in annealed state

Grindability: Low tool wear

Polishing: Accepts mirror finish

7. Welding & Joining Technologies

Recommended Welding Processes:

Gas Metal Arc Welding (GMAW):

Wire: ER5183, ER5356 or ER5556

Shielding: Argon or Ar/He mixtures

Friction Stir Welding (FSW):

Parameters: 600-800 RPM, 150-300 mm/min

Strength Ratio: 85-95% of base metal

Laser Welding:

Power: 4-8 kW fiber laser

Speed: 2.5-5 m/min

Stud Welding:

Capacitor discharge type

Joint Design Specifications:

Butt Joints: 60-70° included angle

Fillet Welds: 6mm min leg length

Double-Sided Welds: Preferred for >10mm thickness

Interpass Temperature: <90°C maintained

8. Physical Properties for Marine Design

| Property | Value | Marine Application Significance |

| Density | 2.66 g/cm³ | Buoyancy calculations |

| Melting Range | 570-640°C | Fire safety margins |

| Thermal Conductivity | 117 W/m·K | Heat exchanger applications |

| Electrical Conductivity | 29% IACS | Shipboard electrical systems |

| Specific Heat Capacity | 900 J/kg·K | Thermal management in engines |

| Young’s Modulus | 70 GPa | Structural stiffness |

| CTE (20-100°C) | 23.8 ×10⁻⁶/K | Expansion joint design |

| Magnetic Permeability | 1.000022 | Degaussing compatibility |

| Thermal Neutron Cross-Section | 0.22 barns | Nuclear marine applications |

9. Quality Control & Certification

Testing Protocol:

Chemical Analysis: OES for each melt

Mechanical Testing: Each plate tested

Corrosion Testing:

ASTM G67: Nitric acid mass loss test

ASTM G66: ASSET test for β-phase

EXCO test per ASTM G34

NDT Methods:

Ultrasonic per ASTM B594 Level A

Radiography for weldments

Leak testing for tanks

Macro/Micro Examination: Grain structure analysis

International Certifications:

Marine Classifications: ABS, DNV, LR, BV

Pressure Vessel Codes: ASME Section VIII

Offshore Standards: NORSOK M-120/M-121

Military Specs: MIL-DTL-24441

International Standards: EN 1090 EXC3/4

Welding Certifications: ISO 3834-2

NACE Compliance: MR0175/ISO 15156

10. Industrial Applications & Handling

Primary Marine Applications:

Ship hulls and superstructures

Offshore platform decks

LNG carrier containment

Ballast water tanks

Submarine pressure hulls

Helicopter landing decks

Marine riser systems

Desalination plant components

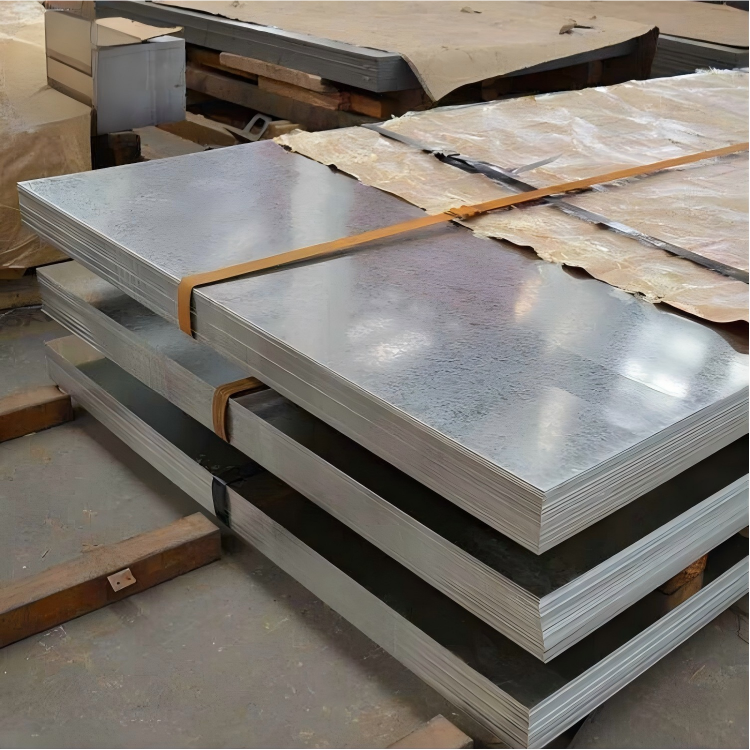

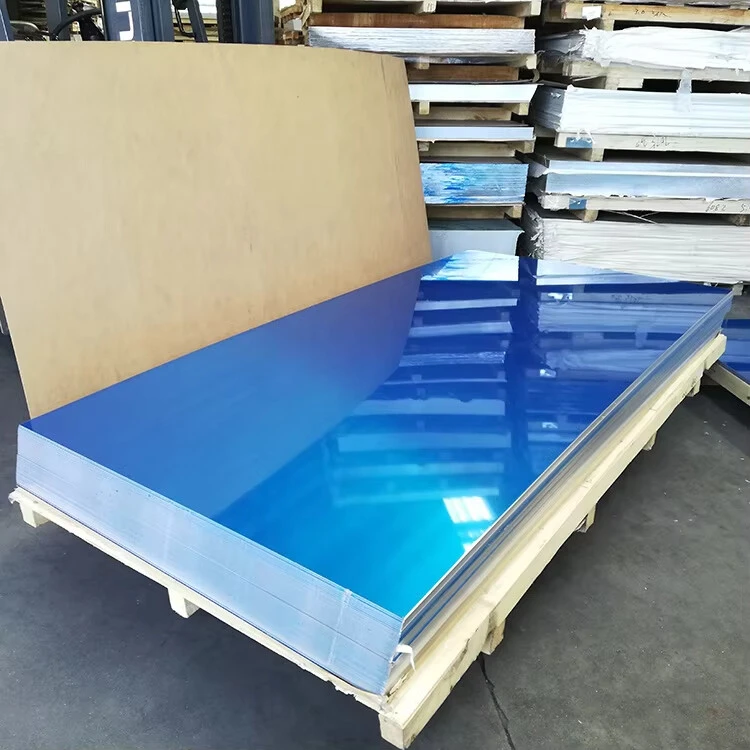

Handling & Storage Protocol:

Storage Temperature: 10-40°C

Humidity Control: <60% RH

Stacking Requirements:

Wood spacers every 500mm

Stack height limit: 1.2 meters

Surface Protection:

UV-resistant PE film

VCI paper interleaving

Lifting Equipment:

Wide pad vacuum lifters

Non-magnetic spreader beams

Edge protection sleeves

Transportation Specifications:

Seaworthy packaging

Desiccant units in containers

ISO container compatibility

Weatherproof covering

Specialized cradle systems

Shock indicators for sensitive parts