1. Material Composition & Manufacturing Process

6061 aluminum alloy (ASTM B209, AMS QQ-A-250/11) is a heat-treatable Al-Mg-Si alloy optimized for high strength-to-weight ratio applications. The T6 temper provides optimal mechanical properties through solution heat treatment and artificial aging:

Alloy Chemistry:

Magnesium (Mg): 0.8-1.2% (solution strengthening)

Silicon (Si): 0.4-0.8% (precipitation hardening)

Copper (Cu): 0.15-0.40% (enhanced machining)

Chromium (Cr): 0.04-0.35% (grain control)

Iron (Fe): ≤0.70% max

Base Material:

Aluminum (Al): ≥97.5% (balance)

Controlled Impurities:

Zinc (Zn): ≤0.25% max

Titanium (Ti): ≤0.15% max

Manganese (Mn): ≤0.15% max

Thermomechanical Processing:

Direct Chill Casting: 680-710°C molten temperature

Homogenization: 540-560°C for 8-12 hours

Hot Rolling: Reduction at 430-490°C

Cold Rolling: Final gauge reduction (15-25%)

Solution Heat Treatment: 530°C ±5°C for 1-2 hours

Water Quenching: Cooling rate >200°C/min

Artificial Aging: 160-180°C for 8-12 hours

Certified to AMS 4025 and EN 485 standards with full traceability from billet to finished plate.

2. Mechanical Properties of T6 Temper State

| Property | Minimum | Typical | Test Standard | Notes |

| Ultimate Tensile Strength | 260 MPa | 310 MPa | ASTM B557 | Superior to T651 temper |

| Yield Strength (Rp0.2) | 240 MPa | 275 MPa | ASTM B557 | 95% retention at 100°C |

| Elongation (50mm gauge) | 10% | 12-17% | ASTM B557 | Higher in thicker sections |

| Shear Strength | 170 MPa | 205 MPa | ASTM B769 | 85% of tensile strength |

| Bearing Strength | 480 MPa | 530 MPa | ASTM E238 | e/D=2.0 condition |

| Fatigue Strength (10⁷) | 95 MPa | 110 MPa | ASTM E466 | R=-1 condition |

| Hardness (Brinell) | 95 HB | 100 HB | ASTM E10 | Consistent through plate |

| Impact Toughness (Charpy) | 14 J | 18 J | ASTM E23 | At room temperature |

| Fracture Toughness (K₁c) | 29 MPa√m | 34 MPa√m | ASTM E399 | T-L orientation |

3. T6 Heat Treatment & Microstructure Control

Precision Thermal Processing:

Solution Treatment:

Temperature: 529-533°C (±3°C control)

Soak Time: 60 minutes minimum per inch thickness

Atmosphere: Protective nitrogen environment

Quenching Process:

Transfer Time: <15 seconds furnace-to-quench

Water Temperature: 20-40°C (chiller controlled)

Agitation: Turbulent flow >1.5 m/sec

Aging Treatment:

Single Stage: 165-175°C for 8-10 hours

Double Stage: 120°C/5hr + 175°C/8hr (special)

Microstructural Characteristics:

Grain Size: ASTM 6-7 (50-100μm)

Precipitate Phases:

β” needle precipitates (5-50nm length)

β’ rod-like phases (100-500nm)

Secondary Precipitates:

Al-Fe-Si dispersoids

Mg₂Si hardening phases

Dislocation Density: 4-6×10¹⁰/cm²

Recrystallization Fraction: 75-90%

4. Dimensional Specifications & Tolerances

| Parameter | Standard Range | Commercial Tolerance | Precision Tolerance |

| Thickness | 3-150 mm | ±0.5-1.0% | ±0.1-0.3% |

| Width | 1000-3000 mm | ±10 mm | ±2 mm |

| Length | 2000-12000 mm | +20/-0 mm | +5/-0 mm |

| Flatness | N/A | ASTM B209 Class | 1/4 commercial spec |

| Surface Roughness | N/A | 0.8-1.5 μm Ra | 0.2-0.4 μm Ra |

| Squareness | N/A | ≤2 mm/1000 mm | ≤0.5 mm/1000 mm |

Special Capabilities:

Oversize Plates: Up to 4500mm wide × 18000mm long

Ultrasonic Calibration: ASTM B594 Level A

Edge Conditions: Plasma cut, machined, or mill finish

Weight Calculation Formula: Thickness (mm) × Width (m) × Length (m) × 2.703 = Weight (kg)

5. Corrosion Resistance & Surface Protection

| Environment | Performance | Corrosion Rate | Protection Method |

| Industrial Atmospher | Good | 0.005-0.02 mm/yr | Chromic acid anodizing |

| Marine Environments | Fair | 0.01-0.03 mm/yr | Fluoropolymer coating |

| Fresh Water | Excellent | Negligible | PTFE impregnation |

| Chemical Exposure | Varies | Acid-dependent | PVDF coating |

| Stress Corrosion | Good | SCC threshold>150MPa | Special tempering |

Surface Enhancement Options:

Anodizing:

Type II: 5-25μm thickness

Type III: 25-75μm hardness

Chemical Conversion:

Chromate (Class 1A)

Chromium-free alternatives

Organic Finishes:

Powder coating (60-120μm)

Liquid coatings (EP, PU, Acrylic)

Embossing Options:

Diamond plate pattern

Linear tread patterns

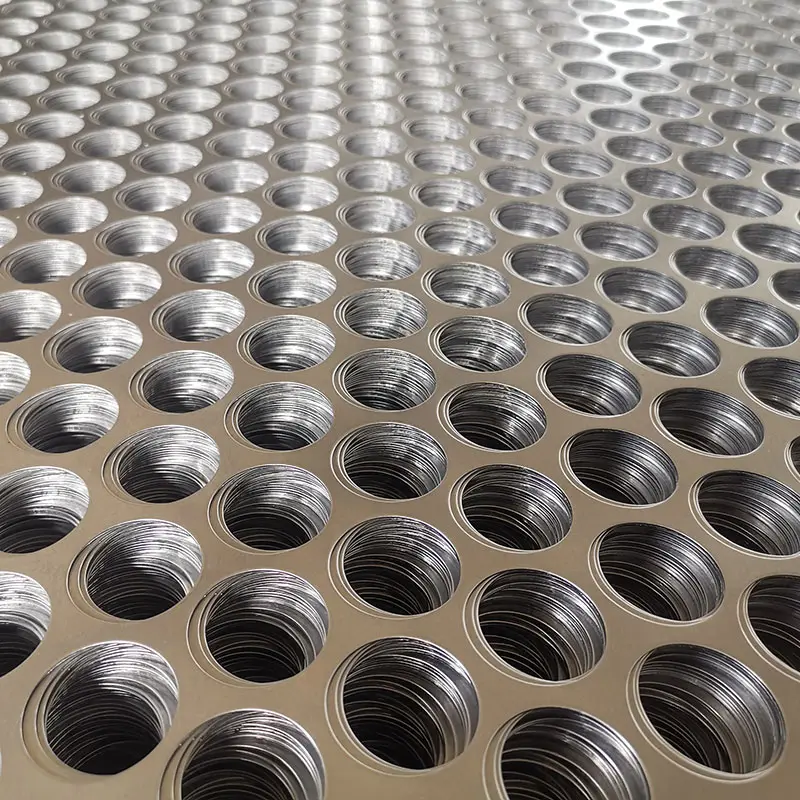

6. Machining & Fabrication Performance

| Operation | Tool Material | Recommended Parameters | Surface Quality |

| Milling | Carbide inserts | Vc=500-800 m/min, fz=0.1-0.3 mm | Ra 0.8-1.6 μm |

| Drilling | HSS-Co drills | Vc=50-80 m/min, fn=0.1 mm/rev | Hole tolerance H9 |

| Turning | PCD tools | Vc=800-1200 m/min | Ra 0.4-0.8 μm |

| Tapping | Spiral taps | Vc=10-15 m/min | 6H thread quality |

| Waterjet Cutting | 3800 bar abrasive | Speed=150-300 mm/min | ±0.15 mm precision |

Forming Characteristics:

Bend Radius (Minimum):

90° bending: 1.5T (T=thickness)

Cold forming: 2.0T minimum

Elastic Springback: 1-3° compensation required

Stretch Formability:

Maximum elongation: 8-10%

Strain hardening exponent: 0.08-0.12

7. Welding & Joining Technologies

Recommended Welding Processes:

Gas Metal Arc Welding (GMAW):

Wire: ER4043 or ER5356

Parameters: 20-24V, 160-220A

Gas: Argon (100%) or Ar/He mix

Tungsten Inert Gas (GTAW):

Electrode: Ceriated tungsten

Amperage: 150-300A DCEN

Friction Stir Welding (FSW):

Tool rotation: 600-1200 RPM

Travel speed: 150-350 mm/min

Post-Weld Heat Treatment:

Solution heat treatment: Not recommended

Aging Only: 165°C for 4-6 hours

Natural Aging: T4 condition restored after 4 days

8. Physical Properties for Engineering Applications

| Property | Value | Application Significance |

| Density | 2.70 g/cm³ | Lightweight structural design |

| Young’s Modulus | 68.9 GPa | Stiffness calculations |

| Poisson’s Ratio | 0.33 | Finite element analysis |

| CTE (20-100°C) | 23.6 ×10⁻⁶/K | Thermal expansion consideration |

| Thermal Conductivity | 167 W/m·K | Heat dissipation applications |

| Electrical Conductivity | 40% IACS | Electrical enclosures |

| Melting Range | 582-652°C | High-temperature limitations |

| Magnetic Permeability | 1.00002 | Non-magnetic applications |

| Specific Heat Capacity | 896 J/kg·K | Thermal management systems |

9. Quality Control & Certification

Testing Protocol:

Chemical Analysis: Spark OES for all shipments

Mechanical Testing:

Tensile tests: Each 2000kg lot

Hardness: Multiple locations per plate

Non-Destructive Testing:

Ultrasonic: Per ASTM B594 Level A

Dye Penetrant: ASTM E1417

Corrosion Testing:

ASTM G47 for SCC assessment

ASTM G67 for intergranular corrosion

Certification Compliance:

ISO 9001:2015 Quality System

AS9100 Aerospace Certification

NADCAP Accredited Heat Treating

PED 2014/68/EU Compliance

NACE MR0175/ISO 15156

ASME Boiler and Pressure Vessel Code

AMS 2770 Heat Treatment Standard

10. Industrial Applications & Handling

Core Application Sectors:

Aerospace structural components

Marine frames and decking

Automotive chassis and frames

Defense vehicle armor plating

Robotics structural elements

High-performance bicycle frames

Semiconductor equipment

Architectural structural elements

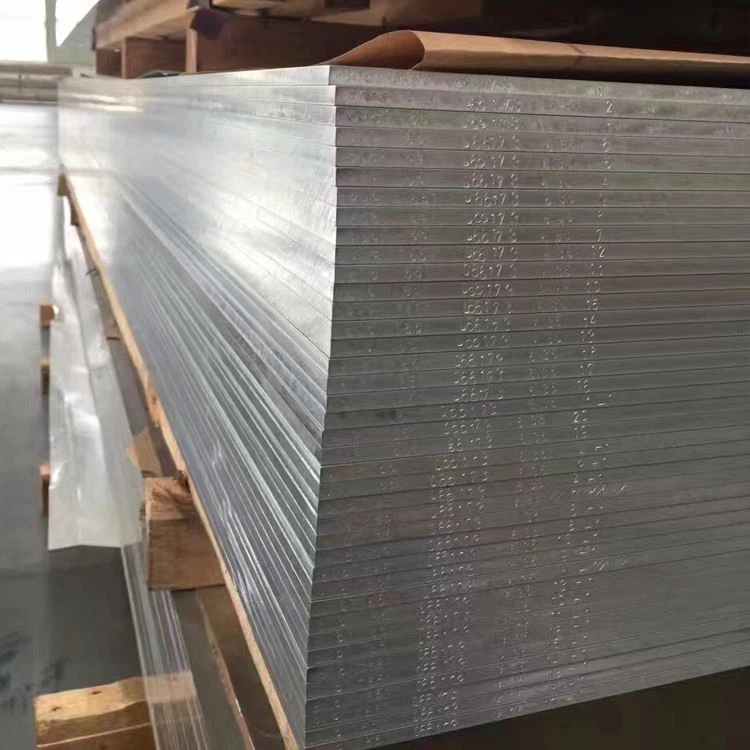

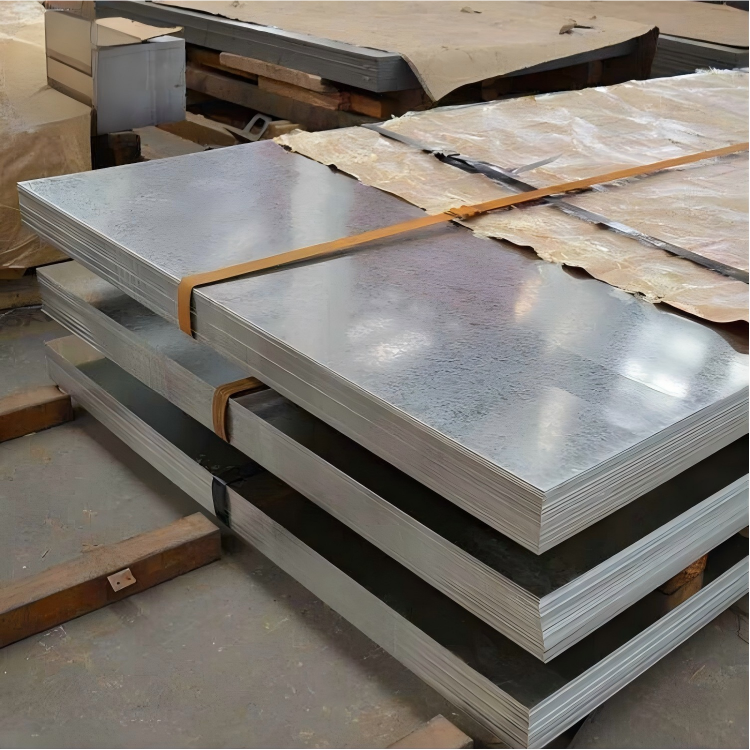

Storage & Handling Protocol:

Storage Orientation: Vertical or flat with even support

Environmental Controls:

Temperature: 15-30°C

Humidity: <60% RH

Surface Protection:

Protective plastic film

VCI (vapor corrosion inhibitor) paper

Stacking Requirements:

Wood spacers every 300-500mm

Maximum stack height: 1000mm

Handling Equipment:

Vacuum lifting systems

Non-magnetic hooks

Edge protectors on slings

Cutting & Fabrication Precautions:

Plasma cutting parameter control

Waterjet cutting angle precision

Machining coolant requirements

Pre-bending heat treatment considerations

Post-weld aging recommendations